What is the strongest drill bit for hardened steel?

Drilling through hardened steel is no easy task—it destroys weak tools in seconds.

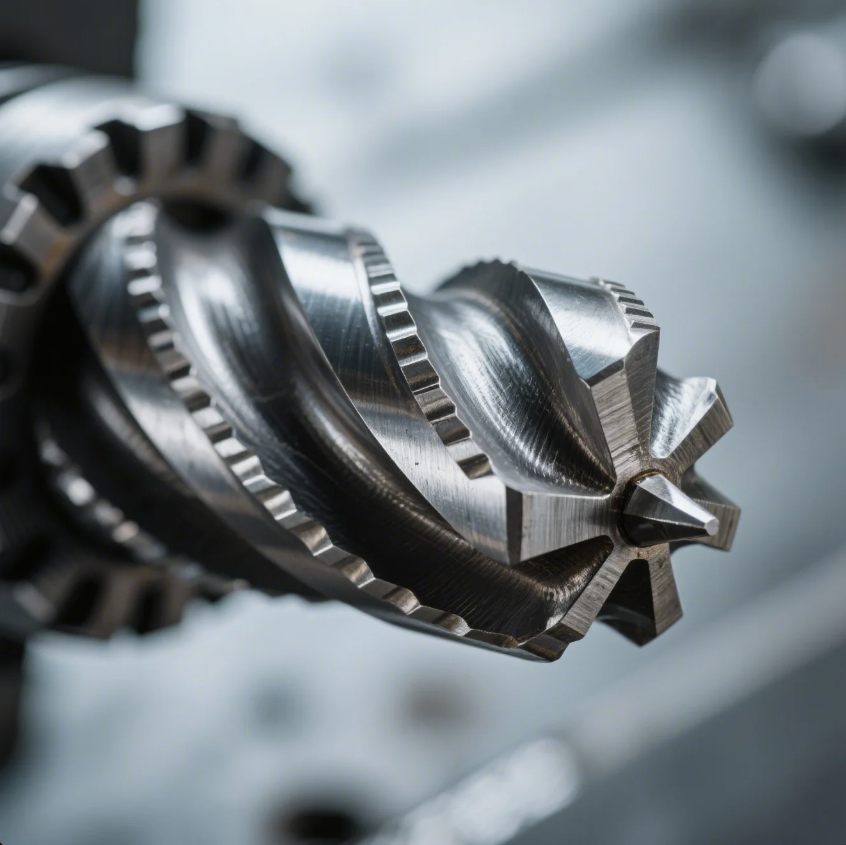

The strongest drill bit for hardened steel is a solid carbide bit. Cobalt bits also work well but wear faster under extreme heat.

In this article, I’ll explain which drill bits are best for hardened steel, how to choose the right angle, and when to use coatings like titanium nitride for better performance.

What is the best drill bit for drilling through hardened steel?

Ordinary bits won’t work. You need tools designed for high heat and hardness.

The best drill bits for hardened steel are solid carbide or high-cobalt (M42) bits, preferably with a titanium coating.

Top-performing drill bits for tough metal

| Drill Bit Type | Hardness Rating | Best For |

|---|---|---|

| Solid Carbide Bit | Extremely hard | CNC machining, small holes, high volume |

| Cobalt Bit (M42) | Very hard | General shop use, deep holes |

| Carbide-Tipped Bit | Hard edges | Field use, hand drills |

At Prime, we use solid carbide bits for CNC零件精准加工, especially on hardened steel parts for mining, defense, and automotive projects.

What is the best drill bit angle for hardened steel?

Bit angle determines how easily the tip cuts through metal without slipping.

The best drill bit angle for hardened steel is 135 degrees. It reduces walking and spreads force evenly.

Why 135° split-point is ideal

- Stays centered

- Cuts cleaner

- Reduces heat buildup

| Angle | Best Use | Drawback |

|---|---|---|

| 118° | General metal and plastic | Tends to walk on hard surfaces |

| 135° Split Point | Hardened steel, tough alloys | Needs slower drilling speed |

At Prime, we use 135° cobalt bits on semi-automated drill presses and carbide end mills on CNCs to handle critical holes in hardened components.

Are cobalt or carbide drill bits better for hardened steel?

Both are strong—but one is tougher under stress and heat.

Carbide bits are better for hardened steel. They’re harder and last longer, but cobalt bits are more affordable and versatile.

Comparing cobalt and carbide bits

| Property | Cobalt (M42) | Solid Carbide |

|---|---|---|

| Hardness | High | Very High |

| Heat Resistance | Excellent | Superior |

| Durability | Medium to high | Extremely high |

| Price | Moderate | Expensive |

| Application | Hand drills, presses | CNC, high-precision jobs |

We often recommend cobalt bits for field use or low-volume work, and solid carbide for production batches or when extreme wear resistance is required.

Will titanium drill through hardened steel?

Titanium coatings help—but they’re not the core cutting material.

Titanium-coated bits can drill through hardened steel, but only if the core is cobalt or carbide. The coating alone is not enough.

What titanium coatings actually do

- Reduce friction

- Increase bit life

- Improve heat resistance

| Coating Type | Benefit | Limitation |

|---|---|---|

| TiN (Titanium Nitride) | Reduces heat and friction | Wears off over time |

| TiAlN or TiCN | Higher resistance for CNC speeds | Still needs hard core bit |

| No Coating | Lower cost, wears faster | For soft materials only |

At Prime, we use coated carbide drill bits on tough components to ensure precision and reduce tool change frequency in production.

Conclusion

Solid carbide bits are the strongest for hardened steel. Use 135° angles and coatings for best results.

Need help with precision machining hardened steel? Contact Shandong Prime International Trade Co., Ltd. today. We offer CNC drilling, carbide tooling, and ISO-certified production with global delivery. Let us help you drill better—faster, deeper, and stronger.