What is the surface coating process?

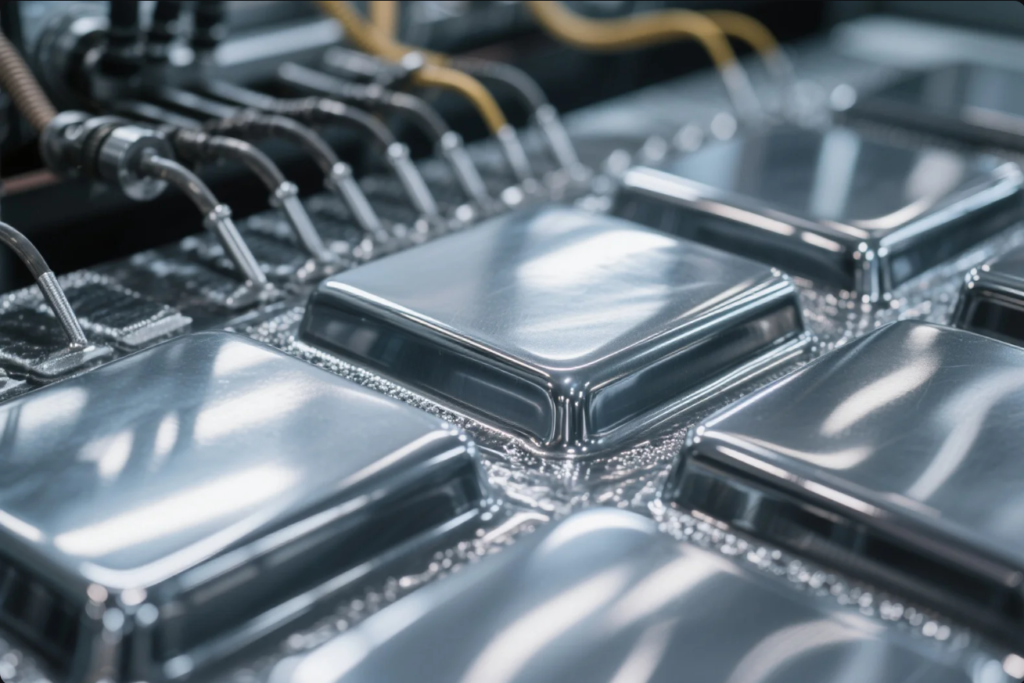

Surface coating enhances part protection, color, and performance—but what exactly happens during the process?

The surface coating process involves surface preparation, application of the coating material, curing, and final inspection.

In this article, we’ll explain how surface coatings work, the key steps, their role compared to heat treatment, and how advanced coating integrates with thermal processing in industrial applications.

What are the stages of the heat treatment process?

Before discussing surface coating, it’s important to understand the heat treatment stages that often prepare parts for coating.

Heat treatment involves four main stages: heating, soaking, quenching, and tempering.

Step-by-step breakdown

| Stage | Description |

|---|---|

| Heating | Raise metal temperature to trigger transformation |

| Soaking | Maintain target temp for a specific time |

| Quenching | Rapid cooling to harden the surface |

| Tempering | Reduce brittleness, stabilize structure |

At Prime, we use heat-treated metal parts as the base before applying surface coatings. This ensures both strength and wear resistance in demanding applications like automotive brackets and CNC machine parts.

What is the difference between surface treatment and heat treatment?

Many confuse surface coating with structural hardening. But they’re distinct.

Surface treatment modifies the outer appearance or resistance; heat treatment changes the internal structure.

Key differences between processes

| Feature | Surface Coating | Heat Treatment |

|---|---|---|

| Goal | Protection, appearance, adhesion | Strength, hardness, flexibility |

| Process Type | External layer application | Internal structure alteration |

| Techniques | Powder coating, painting, plating | Carburizing, annealing, quenching |

| Common Materials | Metals, plastics | Mostly metals |

For best results, Prime often combines both: we heat-treat high-wear parts and follow up with powder coating or electroplating based on customer needs.

What are the four types of heat treating processes?

Heat treatment supports surface coatings by improving the base metal.

The four core heat treating methods are annealing, quenching, tempering, and case hardening.

Purpose and application of each

| Process | Use Case | Effect |

|---|---|---|

| Annealing | Softening parts before machining | Makes metal more workable |

| Quenching | Hardening steel parts | Increases surface hardness |

| Tempering | Post-quenching adjustment | Improves toughness |

| Case Hardening | Surface-specific hardening | Ideal for gears, pins, shafts |

These processes help prepare metal parts for later surface coating, ensuring the underlying material supports the coating during use.

What is the process of TF heat treatment?

TF (Thermochemical Finish) heat treatment is often paired with advanced surface coating for premium performance.

TF heat treatment diffuses elements like carbon or nitrogen into a surface, improving hardness and chemical resistance.

How TF complements coating

TF-treated surfaces bond better with certain coatings and can withstand high-friction or corrosive conditions. This makes them ideal for military hardware, oilfield tools, and high-wear machine parts.

| TF Process Stage | Purpose |

|---|---|

| Pre-cleaning | Ensure surface purity |

| Thermal-chemical soaking | Diffuse hardening elements |

| Controlled cooling | Prevent cracks and distortion |

| Optional coating stage | Add corrosion resistance/color |

At Prime, we offer TF nitriding + powder coating solutions for components needing dual protection—mechanical and environmental.

FAQs

Q1: Is powder coating a type of surface treatment or heat treatment?

It’s a surface coating technique. Heat is used only to cure the layer, not to alter the metal structure.

Q2: Can you coat parts after heat treating?

Yes. We commonly heat treat first, then apply coatings to avoid high-temp damage to finishes.

Q3: What is the difference between painting and powder coating?

Powder coating is thicker, more durable, and eco-friendly—ideal for industrial use.

Q4: Do coatings add measurable thickness?

Yes. Powder coating adds 60–120μm. Prime compensates for this in part design.

Q5: Can Prime test adhesion and coating thickness?

Absolutely. We offer test reports including cross-cut adhesion, salt spray, and micrometer-based thickness measurements.

Conclusion

The surface coating process protects parts and extends performance—especially when combined with heat treatment for structural strength.

Contact Us

Need surface-coated metal parts, heat-treated fasteners, or dual-process CNC components?

✅ Powder coating, plating, painting, and anodizing

✅ Heat treatment + coating workflows

✅ Full inspection and ISO-certified production

🔗 Website: https://primecustomparts.com/

📧 Email: [email protected]

Work with Prime to get high-performance, coated components made for your industry—delivered fast and globally supported.