What is the surface heat treatment process?

Surface heat treatment improves metal hardness, wear resistance, and fatigue life without changing the entire part.

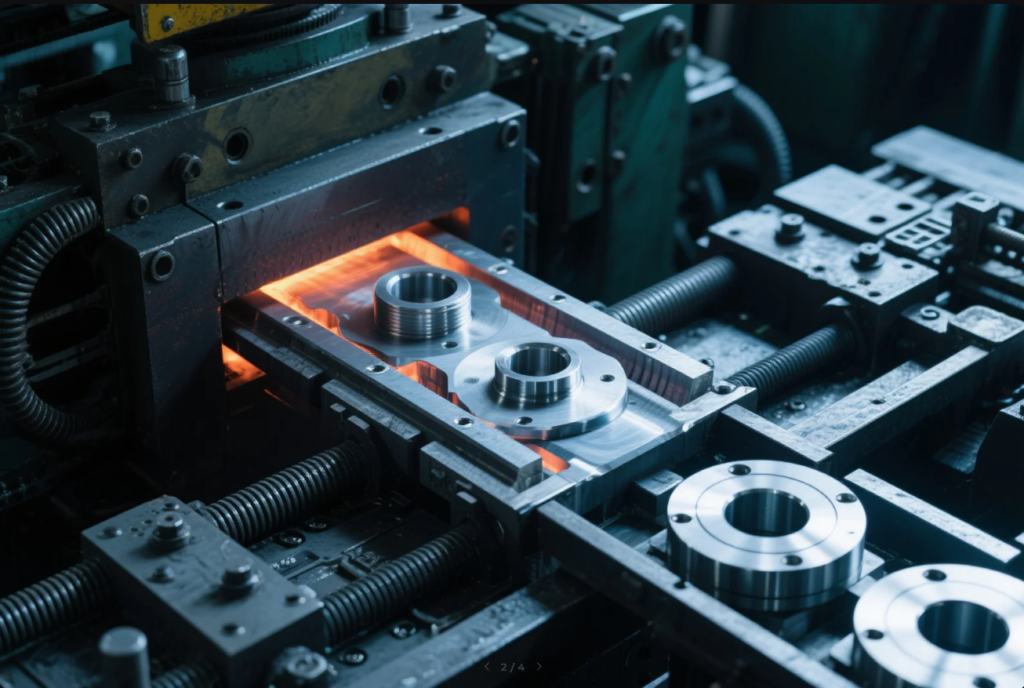

The surface heat treatment process involves heating a metal’s outer layer to change its structure, followed by rapid cooling.

In this article, we explain the steps, techniques, and advantages of surface heat treatment. We also compare it with full heat treatment, explore TF processes, and list common industrial applications.

What are the stages of the heat treatment process?

Heat treatment follows a precise sequence. Skipping a stage can weaken the metal.

The four stages of heat treatment are heating, soaking, quenching, and tempering.

Detailed steps

| Stage | Description |

|---|---|

| Heating | Raise metal temperature to a set level |

| Soaking | Hold that temperature to allow structural change |

| Quenching | Rapid cooling in oil, water, or air to harden |

| Tempering | Reheating at lower temp to reduce brittleness |

At Prime, we apply these stages to key parts like shafts, pins, and gears. This increases hardness and improves service life, especially for high-stress applications.

What is the difference between surface treatment and heat treatment?

Many clients confuse these two. But they serve different functions.

Surface treatment modifies the outer appearance or chemistry; heat treatment alters material structure, often internally.

Key differences at a glance

| Aspect | Surface Treatment | Heat Treatment |

|---|---|---|

| Purpose | Protect or decorate | Harden or soften |

| Depth of Change | Microns to millimeters | Through-thickness or local depth |

| Examples | Painting, plating, anodizing | Carburizing, annealing, hardening |

| Common Materials | Metals, plastics | Mostly metals |

Surface treatments like powder coating add color and corrosion protection. Heat treatments like induction hardening strengthen the part’s load-bearing surface. Prime often combines both in precision metal parts.

What are the four types of heat treating processes?

Heat treatment includes more than just one method. Each has its use.

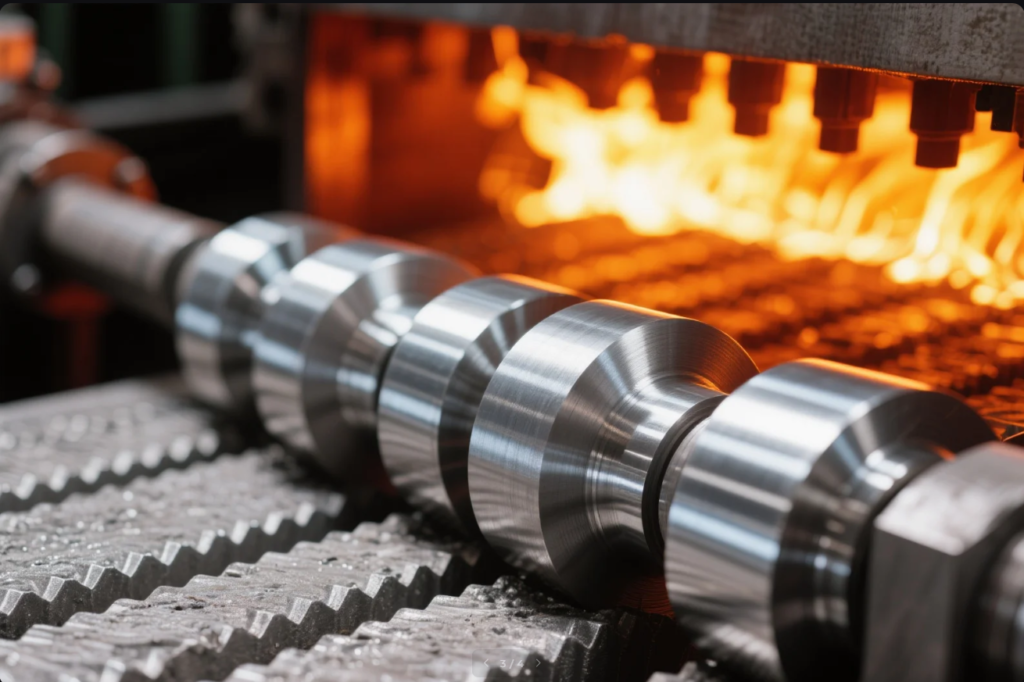

The four common heat treatment processes are annealing, quenching, tempering, and case hardening.

Overview of each process

| Type | Purpose | Application |

|---|---|---|

| Annealing | Soften metal for machining | CNC parts, stamped blanks |

| Quenching | Rapid cooling to increase hardness | Shafts, pins, tools |

| Tempering | Reduce brittleness after quenching | Structural parts, spring steel |

| Case Hardening | Harden only the surface layer | Gears, camshafts, fasteners |

Prime supports custom heat-treated parts with certificates showing depth, hardness (HRC), and cooling method. This ensures full traceability for industries like automotive and aerospace.

What is the process of TF heat treatment?

TF heat treatment (Thermochemical Finish or ThermoFusion) is a surface-specific method used in advanced industries.

TF heat treatment is a surface hardening process combining heat and chemical diffusion to improve wear and corrosion resistance.

How TF differs from standard hardening

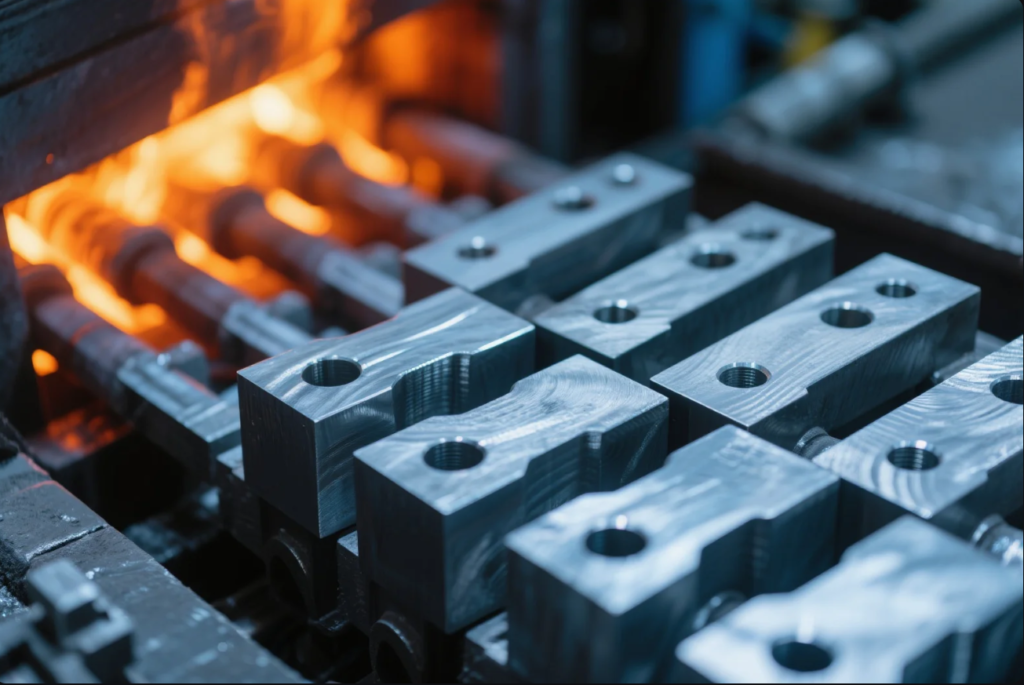

TF treatment adds elements like carbon, nitrogen, or boron to the surface at high temperature. The diffusion depth is controlled precisely, usually under 1mm. This creates an extremely hard outer layer while keeping the core tough and flexible.

TF treatment process steps

| Step | Description |

|---|---|

| Pre-cleaning | Remove all oils, oxides, and residue |

| Heating | Raise temperature to 800–1000°C |

| Chemical Diffusion | Inject gases like ammonia or carbon-rich mix |

| Holding Time | Maintain for hours depending on part size |

| Controlled Cooling | Prevent cracks while maintaining hardness |

At Prime, we use TF nitriding and carburizing methods for industrial pins, bushings, and sliding components that demand high surface wear resistance.

FAQs

Q1: Is surface heat treatment the same as case hardening?

Yes. Case hardening is a type of surface heat treatment focusing on the outer layer.

Q2: What is the maximum hardness surface heat treatment can reach?

Depending on method and material, it can exceed HRC 60 (very hard steel).

Q3: Can aluminum parts be surface heat treated?

Yes, but with different processes like precipitation hardening. Not all aluminum alloys respond.

Q4: Do you offer hardness test reports?

Yes. Prime provides Rockwell, Vickers, or Brinell test reports on request.

Q5: Can you heat treat after CNC machining?

Yes. In most cases, we machine first, then heat treat, then do final grinding if needed.

Conclusion

The surface heat treatment process boosts hardness and wear resistance—without changing internal structure. It’s key for performance parts across industries.

Contact Us

Need heat-treated CNC parts, case-hardened shafts, or TF-treated custom components?

✅ ISO-certified heat treatment partners

✅ Custom hardness, case depth, and material specs

✅ Full traceability with test reports

🔗 Website: https://primecustomparts.com/

📧 Email: [email protected]

Work with Prime to get high-performance, heat-treated parts tailored to your exact specs—fast, tested, and globally trusted.