What is the thinnest sheet metal you can get?

Many buyers want ultra-thin sheet metal1 for high-end industrial needs. However, they often feel lost about what is possible, where to buy, and how to avoid common quality or delivery risks.

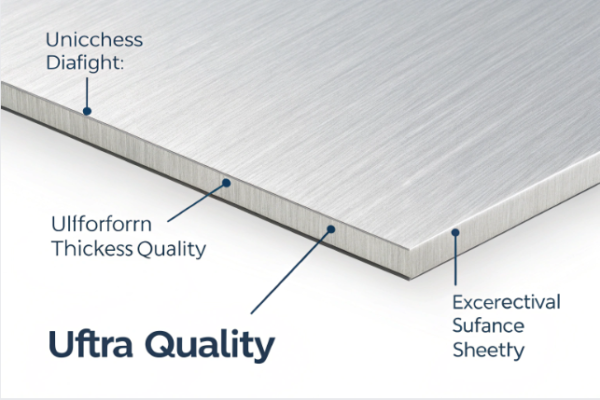

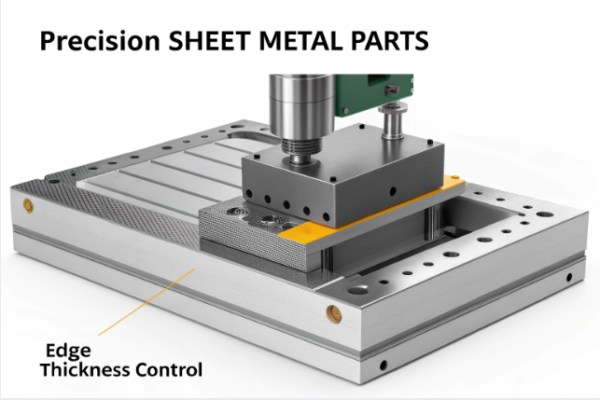

Industrial sheet metal can be as thin as 0.01mm in special alloys, but practical commercial options start at 0.2mm. Buyers should choose reliable ISO certified suppliers2 for the thinnest, most consistent products. Prime offers custom stamping parts, CNC parts, and precision thin metal, supported by advanced inspection and flexible production.

Thin sheet metal creates design advantages in many sectors, but quality and delivery issues1 can become expensive. I have solved these challenges for global clients for over 20 years. Read on for expert insight into choosing, specifying, and sourcing the world’s thinnest, most reliable sheet metal.

What is the thinnest sheet metal?

Every day, customers ask about the absolute minimum thickness of sheet metal1 available for their projects. They want lighter weight2, smaller profiles, and sometimes just lower cost.

The industry defines "foil" as the thinnest metal form, starting at just 0.01mm. Stainless steel foil, for example, can reach 0.03mm. Most “sheet metal” starts from 0.2mm. Prime supports ultra-thin orders1 for both industrial foils and precision stamping parts, with strict ISO-based QC and fast delivery.

Thin sheet metal is essential in electronics, automotive, aerospace, and even medical applications. To maximize value, I recommend discussing the full supply chain1 and technical requirements upfront. Poor planning can lead to failed batches or unusable product. For thin metal, even small mistakes cost a lot.

Dive Deeper: Thin Metal—Performance and Processing Challenges

I have helped clients across North America, Europe, and Australia specify thin metals1 for hundreds of applications. Whenever buyers request thinner gauges, risks increase. For example, thin metal can deform, warp, or crack easily during processing or shipping. You must also consider final installation—ultra-thin metal2 saves weight but may dent or tear during assembly.

H3: Key Physical Properties for Thin Sheet Metal

| Metal Type | Min. Thickness (mm) | Use Case | Key Property |

|---|---|---|---|

| Stainless Foil | 0.03 | Electronics, medical, shims | Corrosion resistance1 |

| Aluminum Foil | 0.01 | Packaging, heat shields | Malleability2 |

| Copper Foil | 0.02 | Circuits, battery tabs | Conductivity |

| Steel Sheet | 0.2 | Auto, covers, enclosures | Strength |

| Brass Shim | 0.05 | Instrument, machinery | Precision fit |

H3: Packaging and Shipping Thin Metals

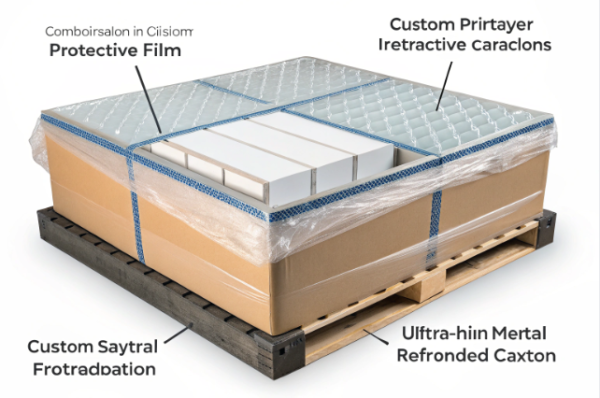

The thinner the metal, the greater the risk in global delivery. I recommend using protective film1, anti-rust paper2, and rigid, reinforced packaging. Prime’s warehouse team always photographs and records each step, ensuring your products arrive in factory condition.

H3: Case Study—Ultra-Thin Stainless for Medical Devices

A European medical device company needed 0.05mm stainless foils1 for a critical sensor. Standard suppliers could not achieve the right flatness. Prime’s team used precision CNC flattening2 and edge deburring to deliver 10,000 flawless sheets within two weeks, saving the customer both time and scrap costs.

What is the lowest thickness of sheet metal?

Buyers sometimes request the lowest thickness1 possible for their application. They seek price advantages, better design fit, or improved thermal or electrical properties2.

The lowest thickness for sheet metal1 depends on both material and process. Aluminum and copper foils can reach 0.01mm. Stainless steel and carbon steel are usually limited to 0.03–0.2mm for safe handling. Prime’s stamping parts and CNC parts support ultra-thin needs2, with advanced tolerance control and ISO certification.

Buyers must balance thinness1 with durability, processability, and cost. For every new project, I review technical drawings2, usage environment, and the expected load or stress.

Dive Deeper: The Engineering Behind Ultra-Thin Sheet Metals

I have seen many projects fail due to chasing the thinnest metal1 without full engineering review2. In reality, the best part balances thickness with functional needs, not just cost.

H3: Technical Risks of Going Ultra-Thin

- Handling: Thin sheets are hard to grip, bend, or weld.

- Forming: Bending or stamping below 0.1mm may cause micro-cracks1 or burrs.

- Joining: Welding or screwing into thin metal2 needs specialized processes.

- Corrosion: Thinner surface exposes more to air and moisture, requiring better coatings.

H3: Thickness Control Methods

| Control Method | Description | Quality Impact |

|---|---|---|

| CNC Precision Grinding1 | Flatness, consistent thickness | ±0.01mm tolerance |

| Automated Inspection2 | Laser or ultrasonic thickness checking | Early detection of variance |

| Certified Raw Material | Only high-grade, traceable coils | Reliable baseline properties |

| Special Packaging | Custom trays, foam, edge guards | Prevents deformation |

H3: Applications of the Thinnest Metals

- EMI/RFI shielding in electronics1

- Flexible circuit production2

- Battery current collectors

- Medical sensors and test strips

At Prime, I have led projects using every thinness on the market. My advice is always to discuss usage, testing requirements1, and packaging needs2 before confirming the order.

What is the thinnest metal you can buy?

Buyers need to know what the market really offers—not just what’s technically possible in a lab.

You can buy metal as thin as 0.01mm, mainly in foil form. Standard steel sheet for industrial use typically starts at 0.2mm. Prime supports special orders for custom thin metal parts1, meeting ISO, DIN, and ASTM standards2.

The thinnest metals are often used for specialized purposes like micro-electronics, sensors, and high-precision spacers. Prime offers both bulk and custom-cut thin metal1, with strict QC2 to prevent defects or size drift.

Dive Deeper: Supply Chain, Customization, and Global Logistics

Most thin metal on the market is available as standard coil or sheet, but many customers need laser cutting1, stamping, or even CNC machining2 for final parts. I have helped hundreds of clients design packaging, labeling, and logistics for these fragile goods.

H3: Sourcing the Thinnest Metal—How to Choose a Supplier

- Certification: Always ask for ISO and origin certificates1.

- Sample policy: Good suppliers send samples with thickness and material certificates.

- Cutting/Processing: For foil and shim, choose suppliers with modern stamping and CNC2.

- Communication: Responsive, technical sales reps save you time and prevent costly mistakes.

H3: Real-World Examples of Thin Metal Products

| Application | Metal Type | Thickness (mm) |

|---|---|---|

| PCB shield cans1 | Tin-plated | 0.2 |

| Precision washers | Brass, SS | 0.05–0.2 |

| Medical shims | Stainless | 0.03 |

| Automotive sensor covers2 | Steel | 0.2–0.5 |

| Battery current collectors | Copper, Al | 0.01–0.05 |

H3: Best Practices—Protecting Ultra-Thin Metal in Transit

Prime uses a three-level packaging system: primary protective film1, secondary anti-static bag, and outer reinforced box. Each lot has a unique QR code for traceability2.

What is a thin sheet of metal called?

Terminology confusion creates risk and miscommunication in global trade. Using the correct name ensures you receive the right material.

Thin metal under 0.2mm is usually called foil, while precision thin parts are called shims. 0.2mm–6mm thickness is typically called sheet metal. Prime supplies foil, shim, and sheet, supporting global B2B clients as a “custom stamping parts supplier1” and “ISO certified casting parts manufacturer2.”

Understanding these terms is essential for technical drawings1, customs clearance2, and supplier communication.

Dive Deeper: Sheet, Foil, Shim—Global Naming Standards

I always clarify the client’s real need using both metric and imperial units, preventing costly errors. For B2B clients, I prepare technical data sheets1 and samples, and support fast prototyping2.

H3: Industry Definitions and Use Cases

| Name | Thickness (mm)1 | Key Application2 |

|---|---|---|

| Foil | 0.01–0.2 | Electronics, packaging |

| Shim | 0.02–0.5 | Gaps, precision spacers |

| Sheet | 0.2–6 | Covers, brackets, panels |

| Plate | 6+ | Structural, frames |

H3: How to Order Thin Sheet Metal—Key Tips

- Always specify both thickness and material grade.

- Request tolerance (e.g., ±0.01mm) and finish (matte, polished, etc.).

- Clarify surface protection needs (oil, film, passivation).

- Ask for packaging photos before shipment.

H3: Certification and QC for Thin Sheet Metal

Prime includes material certificates1, inspection reports2, and packaging details in every shipment, supporting hassle-free customs and global delivery.

Extra: Key Applications for Ultra-Thin Sheet Metal

Ultra-thin sheet metal is not just for electronics. I have delivered solutions for dozens of industries where thinness means better function and cost savings.

H3: Sector Examples

| Sector | Typical Product | Why Use Thin Metal1? |

|---|---|---|

| Aerospace | Heat shields, sensors | Weight reduction, flexibility |

| Medical | Test strip, shims | Precision2, sterility |

| Automotive | Gaskets, sensor covers | Space saving, vibration damping |

| Packaging | Lids, foil wrapping | Barrier, cost-effective |

| Energy | Battery foils, contacts | Conductivity, safety |

I always encourage buyers to send samples or drawings for review. This speeds up quotation and helps avoid future risk.

Extra: How Prime Ensures Quality and Fast Delivery

With over 20 years of experience, Prime has developed systems that ensure stable quality and on-time delivery worldwide.

H3: Prime’s Process Control Highlights

- 10+ advanced production lines for stamping, CNC, welding, and casting

- Full ISO9001/ISO14001 quality certification1

- Multi-level inspection: incoming, in-process, and outgoing

- Custom packaging solutions2 and damage-resistant shipping

- Fast prototyping and flexible order volume for both small and large runs

FAQs

Q1: What is the minimum thickness of stainless steel sheet1 metal you can order from Prime?

A1: We can supply stainless steel foil2 down to 0.03mm, and sheet starting at 0.2mm. Tolerances can be as tight as ±0.01mm.

Q2: Can Prime provide custom packaging1 for ultra-thin parts2?

A2: Yes, we design custom packaging1 (film, trays, foam, etc.) for every order to prevent deformation and scratches.

Q3: How do you guarantee thickness and flatness?

A3: Every batch is measured by digital micrometers1 and laser systems2, with data recorded for traceability.

Q4: Is it possible to order small batch or prototype ultra-thin metal parts1?

A4: Yes, we support flexible order sizes and can deliver small batches2 or prototypes quickly.

Q5: What is the lead time for thin sheet metal parts1?

A5: Standard orders are delivered in 7-15 days. Urgent orders can ship faster.

Q6: Do you provide certificates and testing reports?

A6: Yes, every order comes with ISO material certificates1, test reports2, and detailed packing lists.

Q7: Which countries can you ship to?

A7: We deliver to North America1, Europe2, Australia, the Middle East, and many other regions worldwide.

Q8: How can I get a quotation?

A8: Send your drawings, material, and quantity needs to sales@primecustomparts.com or use our online form at https://primecustomparts.com/contact/.

Conclusion

The thinnest sheet metal depends on your project’s needs. Prime delivers ISO certified1, ultra-thin, custom sheet metal2 worldwide—always on time, with stable quality. Contact us now for a free consultation, quotation, and custom solution.

Contact us:

Website: https://primecustomparts.com/

Email: sales@primecustomparts.com