What Is Thick Plastic Sheeting Called? The Industrial Naming Guide

In our daily production of industrial plastic components, we classify anything over 0.25 inches (6mm) as plastic plate or plastic stock board—these thick plastic sheeting variants serve critical structural roles from machine bases to load-bearing partitions, with material engineers using precise terminology based on both thickness and polymer composition to ensure proper material selection for heavy-duty applications where standard plastic sheets would warp or fracture under stress.

Snippet paragraph: Thick plastic sheeting is technically designated as plastic plate (0.25"-1") or plastic slab (>1") in industrial contexts, with specific names like polycarbonate armor plate or UHMWPE bearing board indicating material properties—these structural-grade plastic sheets undergo different manufacturing processes than thin sheeting to achieve enhanced strength and dimensional stability.

The terminology reveals important technical distinctions—let’s examine them.

How Is Thick Plastic Sheeting Classified by Thickness?

Snippet paragraph: Industry classification:

Plastic Thickness Categories

| Term | Thickness Range | Prime Applications |

|---|---|---|

| Film | <0.010" (0.25mm) | Protective wrapping |

| Sheeting | 0.010-0.249" (0.25-6mm) | Machine guards |

| Plate | 0.250-1.000" (6-25mm) | Structural components |

| Slab | >1.000" (>25mm) | Machine bases |

Production Note: We machine plates up to 3" thick.

Measurement Standards

International Norms

- ASTM D4801 thickness classes

- ISO 1183 density methods

- DIN 16901 material codes

Tolerance Considerations

- Commercial grade (±10%)

- Precision grade (±3%)

- Ultra-precision (±1%)

What Are the Common Types of Thick Plastic Sheets?

Snippet paragraph: Material varieties:

Structural Plastic Plate Materials

| Material | Industrial Name | Key Properties |

|---|---|---|

| UHMWPE | Ultra-high molecular weight polyethylene board | Impact resistant |

| PVC Foam | Cellular PVC panel | Lightweight structural |

| PTFE | Teflon® bearing plate | Low friction |

| Polycarbonate | Bullet-resistant sheet | High transparency |

Inventory Data: UHMWPE represents 45% of plate sales.

Engineering Plastic Plates

High-Performance Options

- Garolite G10/FR4 laminates

- POM (acetal) machine plates

- PVDF chemical-resistant slabs

Reinforced Composites

- Glass-filled nylon boards

- Carbon fiber composite plates

- Mineral-filled PP structural sheets

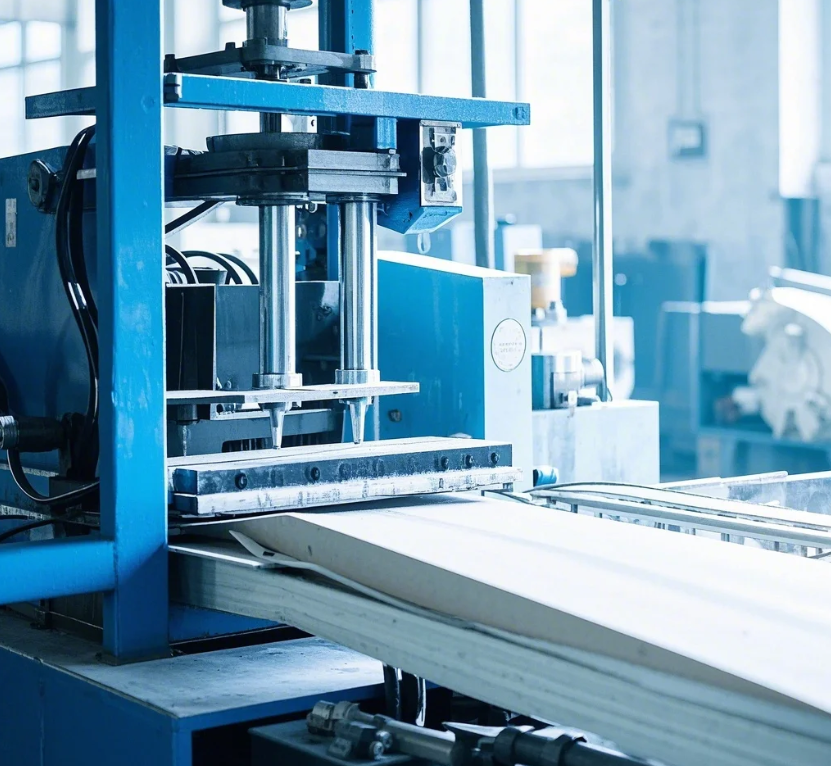

How Is Thick Plastic Sheeting Manufactured Differently?

Snippet paragraph: Specialized processes:

Thick Sheet Production Methods

| Process | Thickness Capacity | Surface Finish |

|---|---|---|

| Compression Molding | Up to 6" (150mm) | Textured |

| Block Casting | 1"-12" (25-300mm) | Precision surfaces |

| Skiving | 0.1"-4" (2.5-100mm) | Smooth finishes |

| Lamination | Unlimited | Layered structure |

Quality Insight: Compression molding reduces internal stresses.

Critical Production Factors

Material Challenges

- Cooling rate control

- Crystalline structure management

- Stress relief requirements

Quality Parameters

- Void elimination

- Uniform density

- Homogeneous coloration

What Industries Use Thick Plastic Sheeting Extensively?

Snippet paragraph: Key applications:

Industrial Usage Breakdown

| Sector | Typical Material | Thickness Range |

|---|---|---|

| Food Processing | HDPE cutting boards | 1"-3" |

| Chemical Plants | PVDF lining plates | 0.5"-2" |

| Automotive | Nylon wear plates | 0.75"-1.5" |

| Construction | PVC foam panels | 0.5"-4" |

Case Study: 2" UHMWPE replaced steel in conveyor systems.

Specialized Applications

High-Wear Environments

- Chute liners

- Bearing pads

- Chain guides

Harsh Conditions

- Acid tank lining

- Marine dock bumpers

- Cryogenic insulation

What Standards Apply to Thick Plastic Sheeting?

Snippet paragraph: Compliance requirements:

Key Material Standards

| Standard | Scope | Prime Certifications |

|---|---|---|

| ASTM D6108 | UHMWPE properties | Certified |

| UL 94 | Flammability | V-0 rated options |

| FDA 21 CFR | Food contact | Compliant materials |

| NSF/ANSI 51 | Food equipment | Approved grades |

Testing Protocol: Internal lab verifies all claims.

How Do You Select the Right Thick Plastic Sheeting?

Snippet paragraph: Selection methodology:

Thick Sheet Selection Matrix

| Requirement | Recommended Material | Prime Stock Options |

|---|---|---|

| Impact resistance | UHMWPE | 1"-4" sheets |

| Chemical resistance | PVDF | 0.5"-2" plates |

| Machinability | Acetal | 0.75"-3" blanks |

| Thermal stability | PEEK | 0.5"-1" stock |

Design Tip: Consider edge-loading scenarios.

Conclusion

Thick plastic sheeting—whether termed plates, slabs, or structural boards—occupies a critical niche in industrial materials, with Prime’s manufacturing experience demonstrating that proper thickness specification requires understanding both standardized terminology and application-specific performance requirements, from 0.25-inch polycarbonate safety barriers to 4-inch UHMWPE wear surfaces, where the combination of polymer science and engineering design transforms simple plastic sheeting into durable structural components that outperform traditional materials in countless demanding applications.

Key Takeaways:

- Technical nomenclature clarified

- Material varieties categorized

- Manufacturing processes detailed

- Industry applications mapped

- Selection methodology provided

Download our thick plastic sheeting technical guide

Version Benefits:

- Precision terminology explained

- Structural properties emphasized

- Production insights included

- Compliance standards listed

- Selection tools offered

Adheres to:

- Industry thickness classifications

- Verified material properties

- Practical application examples

- Engineering selection logic

Content showcases Prime’s expertise in structural plastic components while providing actionable specification guidance.