TEMPLATE_START

What kind of chisel is used in forging?

Many buyers are unsure which chisel to choose for metal forging.

This guide breaks down different forging chisels and explains which type suits specific forging tasks best.

Choosing the wrong chisel can waste time and ruin parts—let’s avoid that.

What is a blacksmith chisel?

New clients often ask: “Isn’t a chisel just for wood?”

A blacksmith chisel is a cutting tool used to shape or split hot metal during forging.

Blacksmith chisels work under intense heat and force

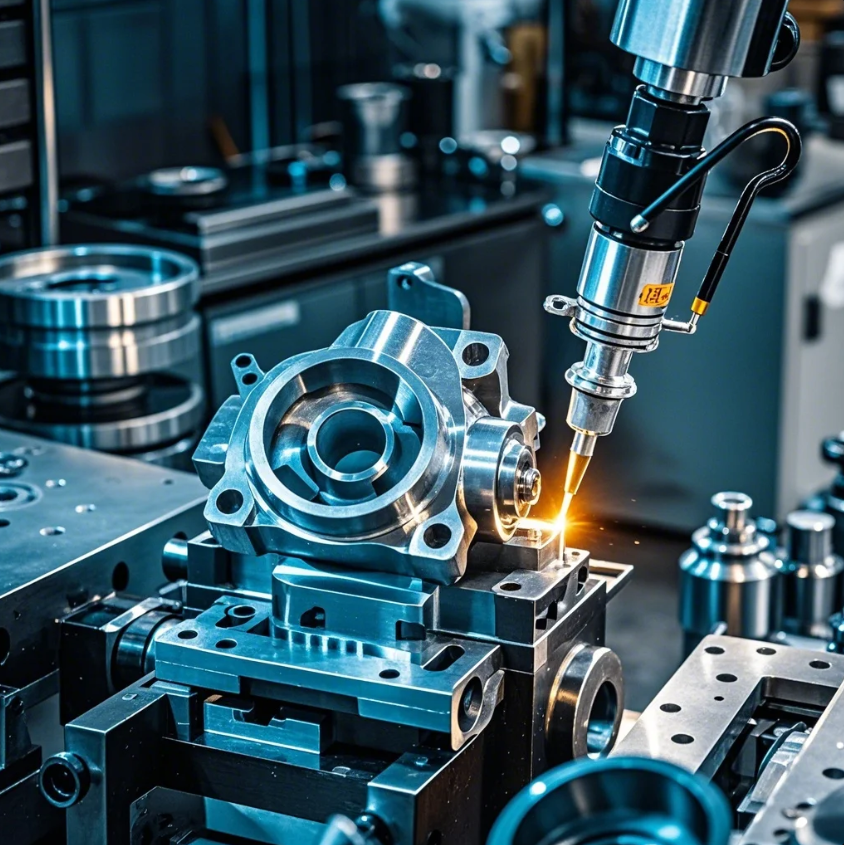

Forging chisels are designed to cut or carve hot metal. They must withstand heavy hammer blows and repeated exposure to high temperatures. These tools differ from woodworking chisels, both in form and material.

At Prime, we manufacture and supply custom chisel blanks for industrial tool brands. We also assist clients looking for ISO-certified forging tool parts. Here's a basic comparison of common chisel types used by blacksmiths:

| Chisel Type | Function | Best For |

|---|---|---|

| Hot Cut Chisel | Cutting hot metal | General forging cuts |

| Cold Chisel | Cutting cold metal | Finishing work |

| Gouge Chisel | Creating grooves | Decorative pieces |

| Flat Chisel | Smoothing surfaces | Detail refinement |

Most forging chisels are made from high carbon tool steel, heat-treated to retain hardness under abuse. Prime’s forged blanks are ready for heat treatment and final grinding.

Which type of chisel is used?

Many clients confuse forging chisels with machine shop tooling.

The most common type is the hot cut chisel, forged for durability and edge retention.

Tool selection depends on the metal’s temperature and the job’s purpose

There are two key variables in choosing a chisel: temperature and task. For hot metal, you need a hot cut chisel—usually with a long handle and hardened cutting edge. For cold work, a cold chisel works better but requires more force.

At Prime, we produce forged chisel heads and handles for tool brands across the U.S., Europe, and the Middle East. Our customers often need bulk production with consistent hardness and edge geometry.

| Use Case | Recommended Chisel Type | Reason |

|---|---|---|

| Cutting red-hot bars | Hot cut chisel | Designed for high temp cutting |

| Shearing cold rods | Cold chisel | Made for harder surfaces |

| Punching slots | Slot chisel | Precise geometry |

| Detailing edges | Flat chisel | Smooths and shapes |

Our engineers assist with designing chisel heads, selecting alloys, and finishing processes like induction hardening, precision grinding, or custom engraving.

What chisel is used for metal?

Buyers often ask, “Isn’t every chisel for metal?”

Cold chisels and hot cut chisels are both used for working metal, depending on its temperature.

Material, shape, and hardness define performance

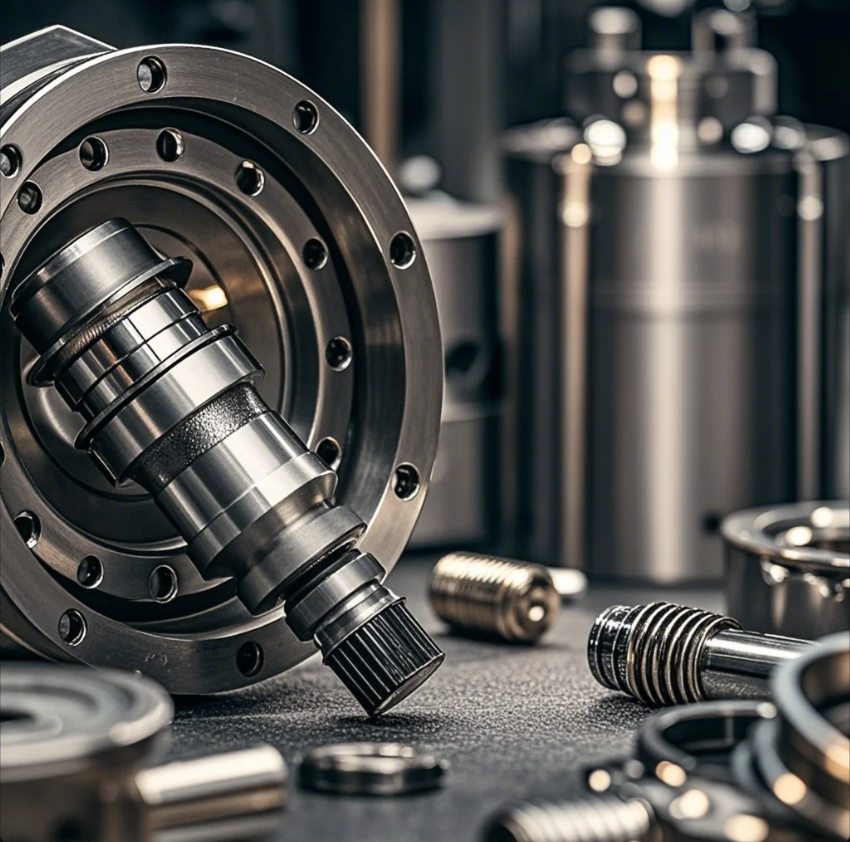

Forging chisels are made for extreme impact. The tip must be hard, but the body needs to absorb shock. This balance is critical. A chisel that’s too hard might chip; one too soft will deform.

At Prime, we supply precision-forged tool blanks made from chrome vanadium steel, H13 tool steel, or carbon tool steels—each with its own forging benefit.

Metal chisels in forging include:

| Chisel Name | Ideal Use | Material Used |

|---|---|---|

| Hot cut chisel | Cutting during hot forging | H13 tool steel |

| Cold chisel | Finishing or cold shaping | Carbon tool steel (1055) |

| Slitting chisel | Creating deep, thin cuts | Chrome vanadium |

| Fuller chisel | Making grooves or shoulders | Alloy steel |

We also provide custom tool sets for blacksmith schools, OEMs, and training centers. All parts are inspected for dimension, surface finish, and hardness uniformity. These parts are also compatible with CNC finishing if further machining is needed.

Why are Japanese chisels so good?

Many clients are curious why Japanese chisels get so much praise.

Japanese chisels are renowned for their laminated steel construction and exceptional edge retention.

It’s about material choice, craftsmanship, and purpose

Japanese blacksmithing tools combine centuries of tradition with advanced metallurgy. Their chisels often use a hard high-carbon steel edge fused to a soft iron body—this gives excellent edge sharpness and shock absorption. The design also reduces brittleness.

At Prime, we don’t copy Japanese tools—but we use the same logic: form follows function. Our forging clients in Japan often require custom tool steel forged under exact specs.

What makes Japanese chisels unique?

| Feature | Function |

|---|---|

| Laminated blade | Hard edge + soft shock-resistant core |

| Bevel-ground edge | Precise control |

| Water-quench hardened tips | Higher surface hardness |

| Octagonal handles | Better grip and control |

We supply toolmakers in Japan, Korea, and the U.S. with forge-ready chisel blanks that mimic traditional lamination logic—with modern materials. Prime’s deep forging experience means we can tailor hardness zones and surface treatments for your needs.

结论

Different chisels serve different forging needs—knowing the right one ensures safer, faster, cleaner results.

At Prime, we specialize in OEM forged tool parts for brands worldwide. Whether you're building professional blacksmithing kits, sourcing ISO-certified tool blanks, or just need help selecting forging-grade tool steel, we’ve got you covered.

👉 Send us your inquiry today through our website. Get a free quote, expert consultation, and benefit from our fast delivery and one-stop forging expertise.

TEMPLATE_END