What Screws Work Best with Aluminum?

In industrial design and fabrication, many professionals wonder what kind of screws to use when working with aluminum components. The answer isn’t as simple as picking any metal screw off the shelf.

Aluminum is soft, lightweight, and chemically reactive, so it requires fasteners that offer strength, resist corrosion, and avoid galvanic failure. This guide covers optimal fastener types, material compatibility, installation techniques, and mistakes to avoid—all based on two decades of manufacturing insight from Prime.

Best Screws for Holding Strength in Aluminum

Due to aluminum’s low hardness, using the wrong screw type may lead to thread stripping or loosening under vibration.

Thread-forming screws, self-tapping variants, and machine screws with metal inserts offer excellent retention in aluminum applications. These screws are designed for soft metals and maintain grip under stress.

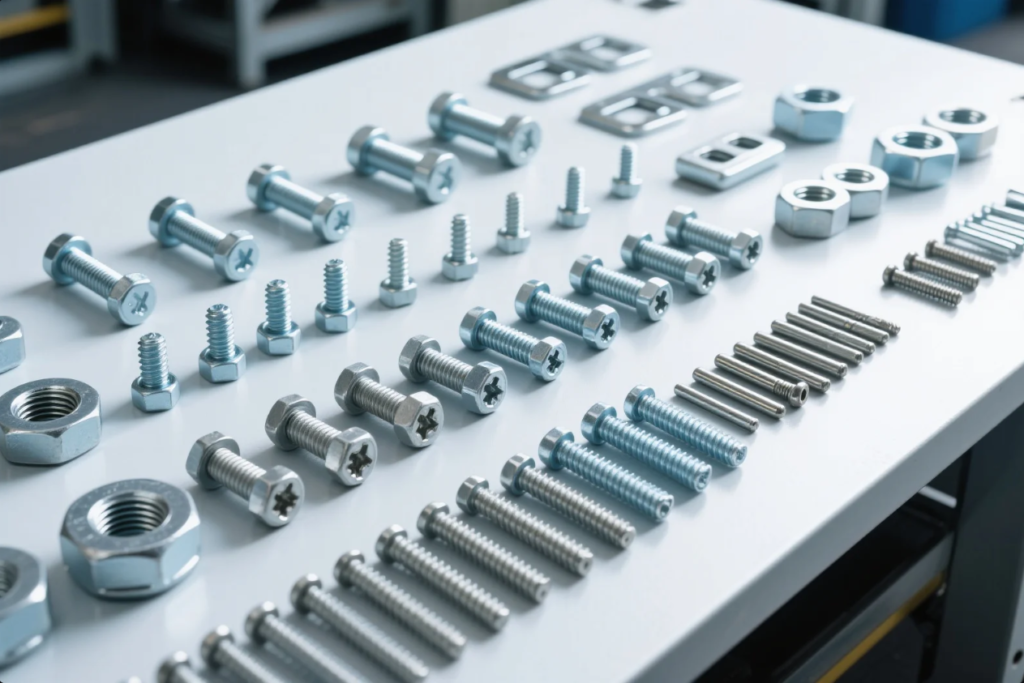

Popular Screw Types and Their Applications

| — | ||||||

|---|---|---|---|---|---|---|

| Self-Tapping | Thin sheet or extruded aluminum | Easy and quick installation | ||||

| Thread-Forming | Dynamic load or machinery use | Improved thread strength, no backing nut | ||||

| Machine + Insert | Thick aluminum blocks or frames | High load tolerance, reusable | ||||

| Stainless Steel | Outdoor or marine hardware | Corrosion-resistant, durable | ||||

| Anodized Aluminum | Aerospace and electrical enclosures | Chemically compatible, lightweight |

Prime supplies standard and custom screws tailored to every aluminum application, with test data for tensile and shear strength available on request.

Material Compatibility: Which Screws Are Safe with Aluminum?

Mixing dissimilar metals without isolation can cause galvanic corrosion. This weakens connections and degrades both fastener and part.

Suitable materials for aluminum include anodized aluminum screws, stainless steel (with barrier isolation), and zinc-coated steel. Uncoated steel, copper, or brass should only be used with dielectric separation.

Galvanic Risk Overview

| — | ||||||

|---|---|---|---|---|---|---|

| Anodized Aluminum | Excellent | No galvanic effect, ideal for matching parts | ||||

| Stainless Steel (304/316) | Good | Use with nylon washers or anti-seize compound | ||||

| Zinc-Plated Carbon Steel | Fair | Indoor use only, avoid moisture | ||||

| Brass | Moderate | Add dielectric paste or plastic washers | ||||

| Raw Steel | Poor | Requires full insulation or coating |

Visit Corrosionpedia to understand metal interaction risks.

Is It Safe to Screw Directly into Aluminum?

Aluminum can accept direct screws if you drill the correct pilot hole, choose the appropriate screw thread, and prevent over-torquing. Self-tapping and thread-forming screws are ideal for this purpose.

Key Guidelines:

- Pilot Hole: Drill to 85–90% of the screw’s minor diameter

- Tooling: Use low-speed, high-control drivers with torque limit

- Thread Locking: Apply thread locker if under vibration or dynamic loads

- Screw Length: Engage at least 1.5x diameter in depth

Prime offers pilot hole size charts and torque recommendations based on screw type and aluminum grade.

Using Stainless Steel Screws with Aluminum Parts

Stainless steel fasteners offer strength and corrosion resistance, making them a popular choice—but they’re not naturally compatible with aluminum.

To safely use stainless fasteners in aluminum, you must prevent metal-to-metal contact using isolators or coatings. This stops galvanic activity and extends part lifespan.

Best Practices:

- Use nylon washers, isolating bushings, or anti-seize paste

- Choose 316 stainless for superior corrosion resistance

- Seal joints in outdoor use to prevent water intrusion

- Avoid direct screw contact with uncoated aluminum

For advanced applications, Prime supplies pre-coated screws or hybrid aluminum-stainless fastening kits.

Installation Tips for Strong Aluminum Fastening

Poor installation technique ruins even the best screw choice.

Recommended Installation Procedure

| — | ||||

|---|---|---|---|---|

| Drill Prep | Use cobalt or TiN drill bits for smooth entry | |||

| Clean Debris | Remove aluminum chips to avoid misalignment | |||

| Tap or Self-Drive | Choose tap or thread-forming screws accordingly | |||

| Apply Torque Control | Use powered drivers with clutch or torque gauge | |||

| Final Check | Retighten after thermal cycling if necessary |

Prime provides on-site and virtual training support for high-volume or mission-critical assemblies.

Common Mistakes to Avoid

Improper fastening can compromise safety, structure, or function.

Frequent Errors & Fixes

| — | ||||

|---|---|---|---|---|

| Thread Stripping | Use correct pilot size and controlled torque | |||

| Loosening Under Load | Add thread locker or spring washers | |||

| Corrosion at Joint | Isolate metals and seal against moisture | |||

| Insert Pull-Out | Use knurled or flanged threaded inserts | |||

| Surface Cracking | Avoid hard corners and sharp transitions |

Every screw Prime ships is tested to meet ISO and customer-defined load or corrosion standards.

FAQs

Q1: Are wood or drywall screws suitable for aluminum parts?A: No. Those screws are too brittle and not designed for metal applications.

Q2: What torque should be applied to small aluminum fasteners?A: For an M4 screw, torque should stay between 2–3 Nm depending on application.

Q3: Should anodizing be done before or after threading?A: Ideally before, but if tapping afterward, compensate for the added oxide layer.

Q4: Can Prime customize aluminum screws with logos?A: Yes. We offer engraving, coloring, packaging, and full OEM branding support.

Q5: How soon can I get fastener samples for testing?A: Samples are available in 5–7 days, including express courier support worldwide.

Conclusion

Using the right screws with aluminum helps ensure strength, safety, and longevity. Whether you\’re building enclosures, machinery, or aerospace assemblies, choosing compatible fasteners and installing them correctly will protect both your part and your reputation.

👉 Need certified fasteners for aluminum-based designs?📌 Visit: https://primecustomparts.com📧 Email: [email protected]

We deliver customized, ISO-approved fasteners for manufacturers, engineers, and industrial buyers across the globe.

Further Reading

Published by Shandong Prime International Trade Co., Ltd. — Trusted by global manufacturers since 1993.