What machine is used for stamping?

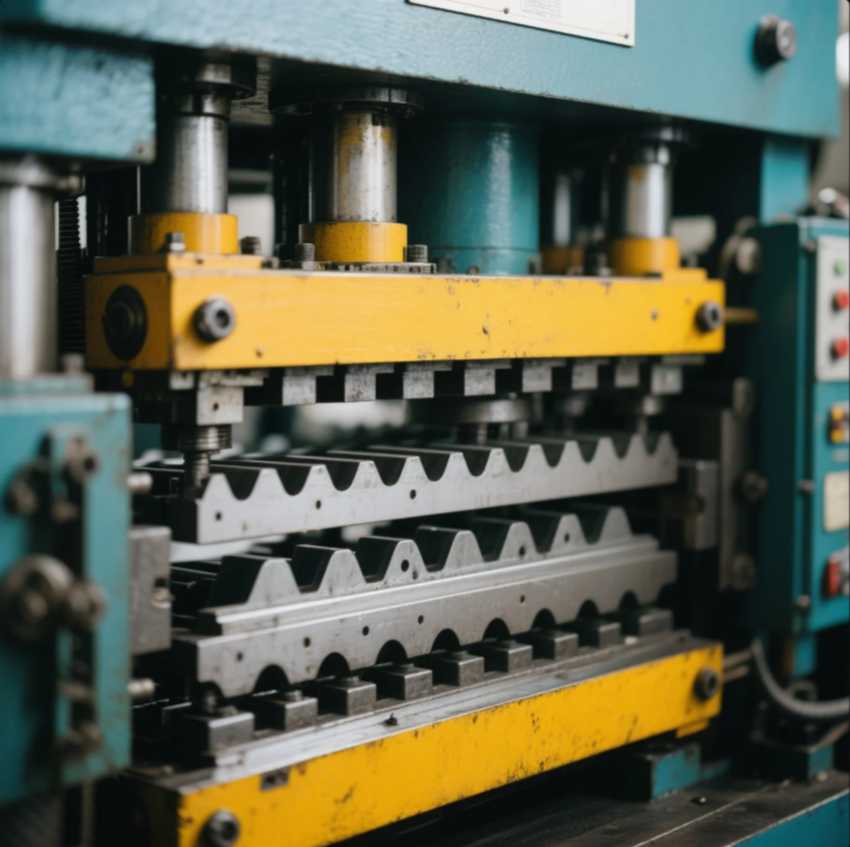

Metal stamping requires high precision, force, and speed to shape components effectively.

Stamping is typically done using a press machine—most commonly a mechanical press or hydraulic press, depending on material and complexity.

Each machine type serves different applications in automotive, electronics, and industrial manufacturing.

What is a stamping machine called?

Stamping machines go by different names depending on the operation and technology used.

A stamping machine is often referred to as a press machine, stamping press, or power press.

These machines apply force through dies to form or cut metal sheets into precise shapes.

Common Terms for Stamping Machines

| Name | Description |

|---|---|

| Press Machine | General term for all force-based shaping tools |

| Stamping Press | Machine used specifically for metal stamping |

| Power Press | Mechanical or hydraulic press with high tonnage |

| Punch Press | Applies force via a punching die |

At Prime, we use both mechanical presses and hydraulic stamping systems to manufacture custom stamping parts for clients across multiple industries.

Which machine is used for stamping?

The right stamping machine depends on the product’s shape, material, and thickness.

The most commonly used machines for stamping are mechanical presses, hydraulic presses, and servo presses.

Each offers different speed, precision, and force capabilities.

Machines Commonly Used for Stamping

| Machine Type | Key Feature | Best For |

|---|---|---|

| Mechanical Press | Fast and consistent | High-volume stamping |

| Hydraulic Press | Controlled pressure | Deep-draw or thick materials |

| Servo Press | Programmable motion control | High precision, complex shapes |

At Prime, we’ve optimized our 10 in-house production lines with all three technologies—ensuring speed and accuracy for every order.

Which tool is used for stamping?

Machines don’t work alone—tools make the shapes.

The main tool used in stamping is a die. Dies are custom-made metal tools that cut, form, or shape the workpiece during stamping.

They define the final shape, tolerance, and surface of each part.

Stamping Tools and Their Functions

| Tool Name | Purpose |

|---|---|

| Punch | Cuts or forms holes |

| Die Set | Shapes the metal with precision |

| Blank Die | Cuts raw material into blanks |

| Progressive Die | Performs multiple steps in one run |

We design custom dies for client-specific parts at Prime, ensuring every stamped product meets ISO-certified tolerance and quality standards.

What are the different types of stamping machines?

Stamping needs vary—from flat parts to deep-formed enclosures.

There are several types of stamping machines: mechanical presses, hydraulic presses, servo presses, and pneumatic presses. Each serves different production needs.

Choosing the right one impacts quality, speed, and cost.

Stamping Machine Types

| Machine Type | Functionality Level | Ideal For |

|---|---|---|

| Mechanical Press | High-speed cycles | Mass production, thin metal parts |

| Hydraulic Press | Controlled pressure | Deep draw, thicker sheets |

| Servo Press | Precision control | Complex shapes, tight tolerances |

| Pneumatic Press | Lower force, faster | Light stamping, small components |

At Prime, we select the right press based on your part’s complexity and volume. Our combination of speed, precision, and flexibility delivers high-quality custom stamping parts across North America, Europe, and beyond.

Conclusion

Stamping machines—like mechanical, hydraulic, and servo presses—shape metal with speed, force, and accuracy.

Contact Prime today to source high-quality, custom-stamped metal parts backed by 20+ years of experience, 10 advanced production lines, and ISO-certified processes. Get fast quotes, expert support, and reliable delivery for your next stamping project.