What Metals Are Not Compatible with Aluminum?

Pairing aluminum with the wrong metal can lead to galvanic corrosion, structural damage, and costly repairs.

In 2025, understanding metal compatibility is critical in manufacturing, construction, and marine applications. This article explores what metals should not be used with aluminum, how reactions occur, and what fasteners are best.

Incorrect metal combinations can weaken joints and destroy aluminum components. Here’s how to avoid these risks and ensure durable assemblies.

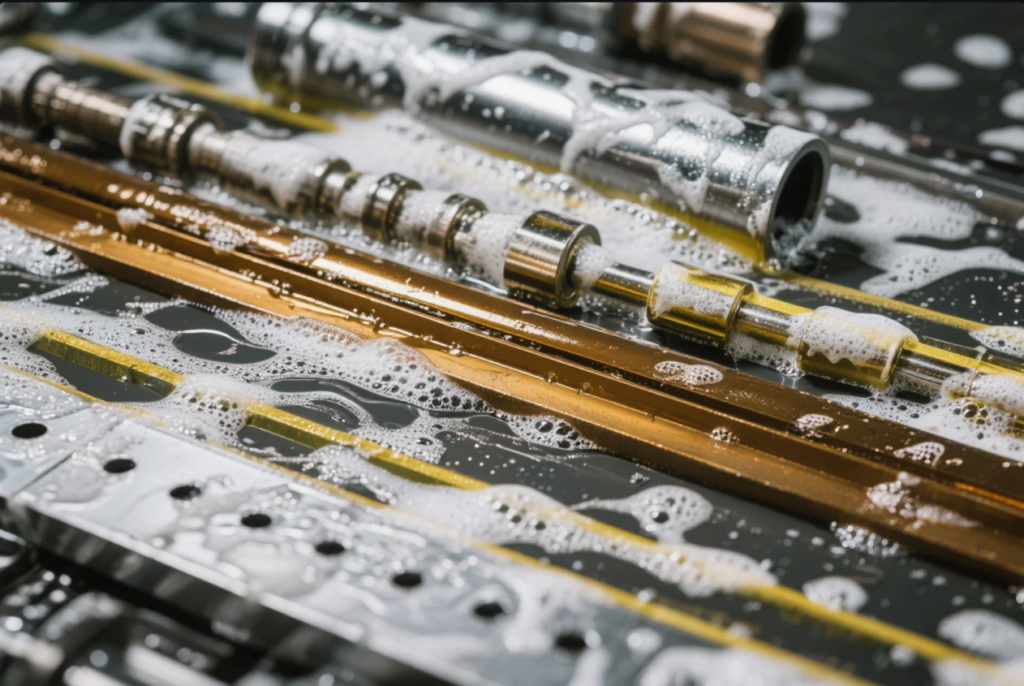

Can You Use Brass Screws in Aluminum?

Brass screws can be used with aluminum in dry environments — but are risky outdoors.

Brass and aluminum are dissimilar on the galvanic scale. When exposed to moisture, this difference creates a galvanic cell, where aluminum becomes the sacrificial metal.

Use Brass Screws ONLY If:

- You’re working in a dry, sealed interior.

- The joint is electrically and thermally isolated.

- You apply barrier coatings or insulating washers.

For marine, outdoor, or high-humidity projects, Prime recommends using stainless steel screws instead to avoid long-term corrosion.

What Metals Do Not React with Aluminium?

The best metals to use with aluminum are those close to it on the galvanic series — meaning they don’t cause an aggressive electrochemical reaction.

Compatible metals include:

- Anodized Aluminum – Perfect match with no reaction.

- Stainless Steel (304/316) – Slight potential difference but generally safe.

- Zinc (with care) – Often used in coatings, though direct contact can be risky in marine environments.

Compatibility Table

| Metal | Compatibility with Aluminum | Use Case Notes |

|---|---|---|

| Anodized Aluminum | Excellent | Same material, no risk |

| Stainless Steel | Good | Ideal with insulation or coatings |

| Coated Brass | Medium | Acceptable indoors only |

| Copper | Poor | Avoid — accelerates corrosion |

| Galvanized Steel | Poor | High corrosion unless isolated |

At Prime, we stock ISO-certified fasteners designed to eliminate compatibility problems with aluminum in industrial, aerospace, and architectural applications.

Can Brass and Aluminum Be Used Together?

Yes — but only under specific conditions.

When brass and aluminum are joined without proper insulation and moisture control, galvanic corrosion can quickly set in. Aluminum corrodes first.

How to Safely Combine Brass and Aluminum

- Use non-conductive washers (nylon, rubber)

- Apply dielectric grease or thread sealant

- Avoid direct contact in wet areas

- Limit use to indoor environments

Prime engineers frequently help clients redesign mixed-metal components using dual-layered screws, polymer-coated fasteners, or anodized spacers to eliminate corrosion risk.

What Kind of Screws Can I Use with Aluminum?

Choosing the right fastener is key to avoiding corrosion and ensuring secure aluminum assemblies.

Recommended screw materials for aluminum:

- Stainless Steel – Preferred for strength and corrosion resistance.

- Anodized Aluminum Screws – Same metal, ideal match.

- Coated Brass (polymer or nickel) – Acceptable for interior use.

Fastener Comparison

| Screw Material | Aluminum Compatibility | Use Notes |

|---|---|---|

| 316 Stainless Steel | Excellent | Ideal for outdoor and marine use |

| 304 Stainless Steel | Good | For general structural applications |

| Anodized Aluminum | Excellent | Lightweight and decorative |

| Brass (bare) | Poor | High galvanic risk outdoors |

| Zinc-Plated Steel | Poor | Avoid unless fully isolated |

Need bulk custom screws for aluminum parts? Prime offers fastener kits with surface treatments, rubber grommets, and OEM logos ready for direct B2B shipment worldwide.

How to Prevent Galvanic Corrosion in Aluminum Assemblies

When pairing aluminum with other metals, you can minimize corrosion with good design and material control.

Five Proven Prevention Techniques

-

Isolate Metals

Use plastic or nylon washers, spacers, or bushings between metals. -

Apply Coatings

Use non-conductive paint, anodizing, or rubber dip on the metal surfaces. -

Select Compatible Metals

Refer to the galvanic series and keep metals close in potential. -

Seal the Assembly

Use waterproof gaskets, RTV sealants, or foam to block moisture. -

Drain Moisture

Design your assembly to prevent pooling water or allow drainage.

Prime supplies fasteners with insulating sleeves, custom coatings, and dielectric greases to ensure your aluminum project stays corrosion-free in any climate.

FAQs

Q1: What’s the worst metal to use with aluminum?

A1: Copper is the most reactive and causes rapid pitting in aluminum under moisture.

Q2: Are zinc-plated screws safe for aluminum?

A2: Not ideal. The zinc corrodes fast and may stain or accelerate aluminum wear unless insulated.

Q3: Can I use stainless bolts in aluminum parts?

A3: Yes. Just add a nylon washer or grease layer to reduce galvanic potential.

Q4: Does anodizing help with mixed-metal corrosion?

A4: Yes. It adds a protective oxide layer that slows down electron transfer between metals.

Q5: Can Prime provide aluminum-compatible fasteners for marine applications?

A5: Yes. We stock marine-grade 316 stainless steel fasteners, complete with sealing washers and labeling.

Conclusion

Not all metals are compatible with aluminum. To avoid galvanic corrosion and mechanical failure, choose stainless steel, anodized aluminum, or specially coated brass screws. For technical support and certified solutions, contact Prime or email us at [email protected]. We deliver fasteners engineered for aluminum — globally, reliably, and affordably.

4 Responses

I actually love your providing this information for folks wanting

to know more about topics like this. Your blog was well

written and well researched, and that is substantially liked.

I actually am generally looking for new blogs to follow and browse on a regular basis.

Upon reflection, I thought your blog is and not keeping your head stuck in the phone the whole while,

either) and living free, living life with appreciation for the natural world, keeps people feeling sane and feeling joyous.

Philosophizing about important memes is likewise an experience of a different order

that can assist us to know ourselves.

I am always seeking for new data about this kind of significant issue,

and was especially happy once I find websites which might be well-written and well-researched.

I want to thank you for featuring this exceptional information, and I look ahead to read more right from the

blog page in the near future.

We value your offering this info for folks aiming

to find out more on subject areas such as this. Your weblog was well-written and very well investigated, that is certainly considerably

treasured. I am always searching for new blogs to follow and read frequently.