What plastic is used in injection molding?

Many buyers and engineers ask which plastic is best for injection molding — but the answer depends on strength, cost, and use case.

Common plastics for injection molding include ABS, PP, PE, PC, and nylon. The choice depends on application, durability, and cost.

At Prime, we guide every client toward the right resin for their custom plastic parts, ensuring balance between performance and price.

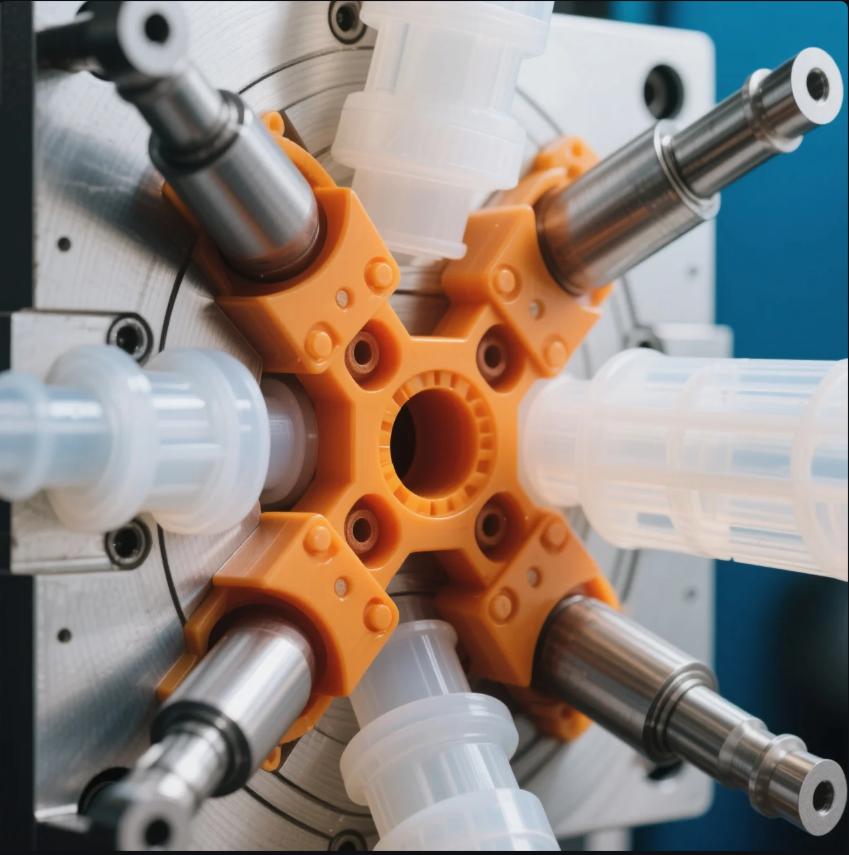

What is the strongest plastic for injection molding?

Strength is key for industrial, automotive, or structural applications — and not all plastics are equal.

The strongest plastics used in injection molding include polycarbonate (PC), nylon (PA), and glass-filled polymers.

One U.S. client needed impact-resistant parts for electrical housings. We used PC with 20% glass fiber, improving strength without affecting molding performance.

Strong Plastics Comparison

| Plastic Type | Key Strength Feature | Common Use |

|---|---|---|

| Polycarbonate (PC) | High impact resistance | Electrical enclosures |

| Nylon (PA) | Tough + abrasion resistant | Gears, automotive parts |

| PBT + Glass Fiber | Stiff, strong, heat stable | Connectors, engine covers |

At Prime, we help clients validate these materials with real-world performance testing and ISO-certified processing.

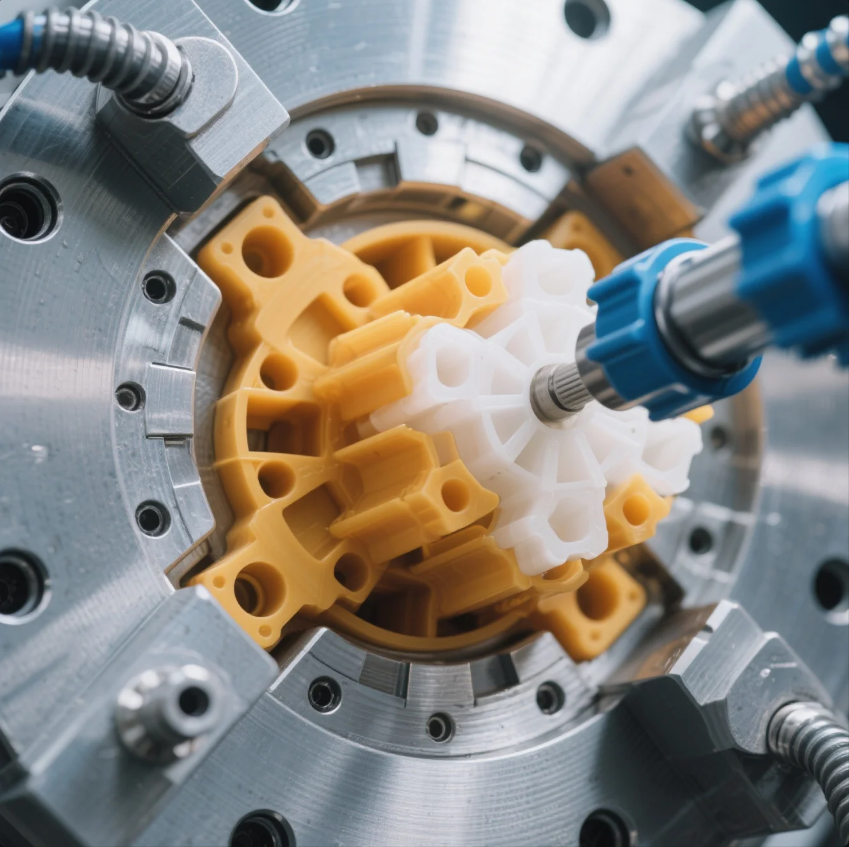

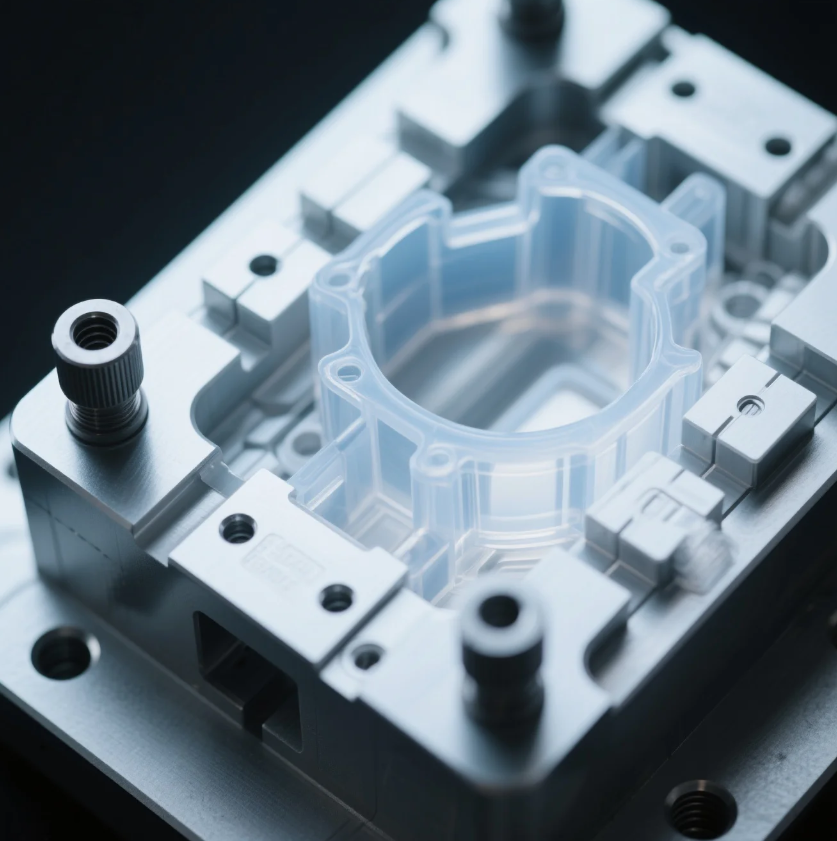

What material are injection molds made of?

The quality of the mold affects precision, lifespan, and cost.

Injection molds are commonly made of steel or aluminum. Steel offers higher durability; aluminum offers faster, cheaper tooling.

We helped a European startup choose aluminum for a 5,000-piece run, saving 40% in tooling while meeting their product specs.

Mold Material Comparison

| Mold Material | Cost | Lifespan | Best Use |

|---|---|---|---|

| Aluminum | Lower | 5,000–100,000 | Prototyping, short runs |

| P20 Tool Steel | Medium | 100,000+ | General production |

| H13 Steel | High | 1,000,000+ | High-volume, high-temperature |

Prime’s tooling service includes both aluminum and steel molds — matched to your part’s requirements.

What is the cheapest plastic for injection molding?

When cost is the main concern, many buyers want the most affordable resin available.

The cheapest plastics for injection molding include polypropylene (PP), polyethylene (PE), and polystyrene (PS).

We helped a Middle East distributor switch from ABS to PP for a non-load-bearing part, cutting material cost by over 35% per unit.

Low-Cost Plastic Options

| Plastic | Cost Efficiency | Typical Use Case |

|---|---|---|

| Polypropylene (PP) | Very low cost, flexible | Consumer goods, packaging |

| Polyethylene (PE) | Cheap, chemical-resistant | Bottles, containers |

| Polystyrene (PS) | Rigid, inexpensive | Housings, disposables |

At Prime, we suggest materials that meet function and budget — not just the lowest price.

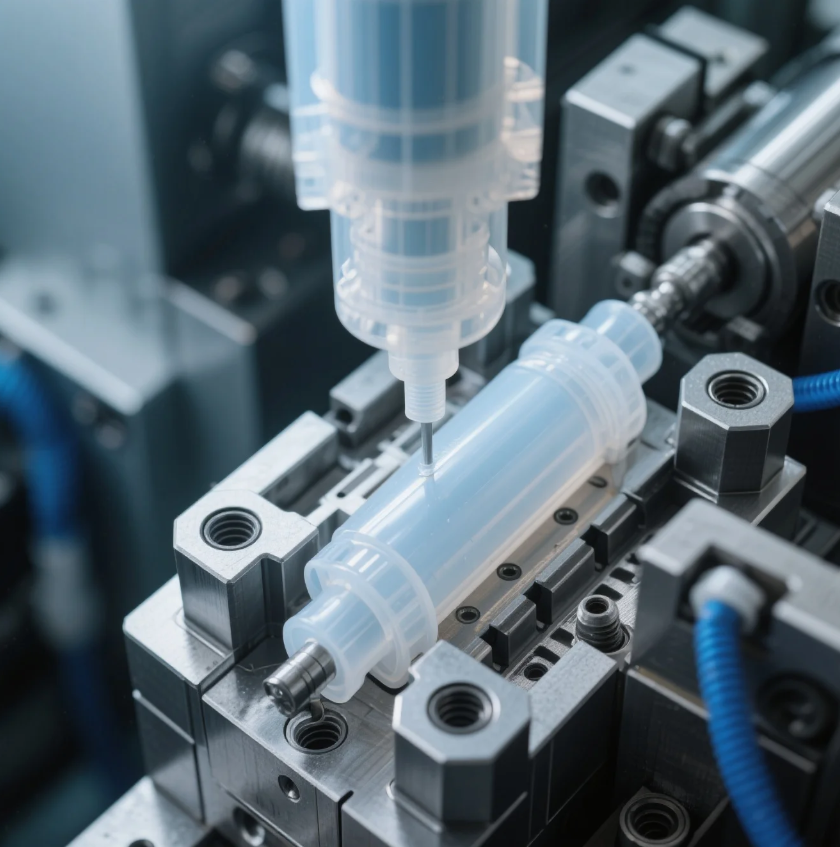

What is the most common raw material for injection molding?

Certain plastics are used across nearly every industry due to versatility and ease of processing.

Polypropylene (PP) is the most common raw material in injection molding, due to its low cost, flexibility, and chemical resistance.

We use PP in many of our high-volume projects — from packaging components to simple mechanical housings — where strength is less critical.

Top Materials in Use Today

| Resin | % Market Use | Industry Application |

|---|---|---|

| Polypropylene (PP) | \~25% | Packaging, caps, trays |

| ABS | \~20% | Electronics, auto interiors |

| Polyethylene (PE) | \~15% | Containers, toys |

| Polycarbonate (PC) | \~10% | Safety covers, lighting |

Prime stocks all common resins and supports custom blends to meet unique specs.

Conclusion

The best plastic for injection molding depends on strength, price, and purpose — with PP, ABS, and PC among the most popular.

Need help choosing the right plastic for your next project? Prime offers free material consultation, DFM analysis, and production quotes. Contact us today to start your custom plastic part journey with the right resin, right mold, and the right partner.