What Screws to Use on Aluminum Boat?

Boat owners and marine engineers often ask: what screws to use on an aluminum boat? Using the wrong fasteners can lead to galvanic corrosion, structural failure, or costly repairs.

The best screws for aluminum boats are marine-grade stainless steel (316), coated aluminum screws, and other corrosion-resistant fasteners designed for saltwater exposure.

In this guide, you’ll learn which fasteners perform best on aluminum hulls and frames, how to avoid corrosion, and how to install screws for long-term durability. This advice is based on decades of experience supplying fasteners to shipbuilders and marine fabricators.

What Kind of Screws to Use in an Aluminum Boat?

Marine environments are highly corrosive—especially where aluminum and saltwater are involved.

Use corrosion-resistant screws such as 316 stainless steel, anodized aluminum screws, or zinc-plated steel with barrier washers. Avoid uncoated carbon steel or copper-based screws.

Recommended Marine Screw Options

| Screw Type | Use Area | Benefits |

|---|---|---|

| 316 Stainless Steel | Deck mounts, hinges, hardware | Corrosion-proof in saltwater |

| Anodized Aluminum | Non-load-bearing interior panels | Lightweight, galvanically safe |

| Coated Steel (zinc/chrome) | Indoor or covered compartments | Budget-friendly, moderate corrosion protection |

| Nylon Screws (limited use) | Electronics or enclosures | Non-conductive, corrosion-free |

At Prime, we help shipyards choose the right screws by offering complete marine-grade fastener kits designed for aluminum vessel use.

What Kind of Screws Do You Use for Aluminum Marine Parts?

Not all aluminum fasteners are created equal—marine exposure adds unique requirements.

For boat-specific aluminum applications, choose screws that resist saltwater, temperature fluctuation, and electrochemical interaction.

Ideal Fastener Features:

- Saltwater resistance

- No galvanic reaction with aluminum

- Anti-vibration properties

- Long-term UV and temperature stability

We offer ISO-certified marine fasteners tested in salt spray chambers, ideal for fishing vessels, pontoon boats, and aluminum yachts.

Can You Use Stainless Steel Screws in an Aluminium Boat?

Yes—with isolation and proper installation.

Stainless steel fasteners (especially grade 316) are safe for aluminum boats if insulated properly. Without insulation, galvanic corrosion may develop quickly, especially in moist bilge areas or saltwater zones.

Protection Methods:

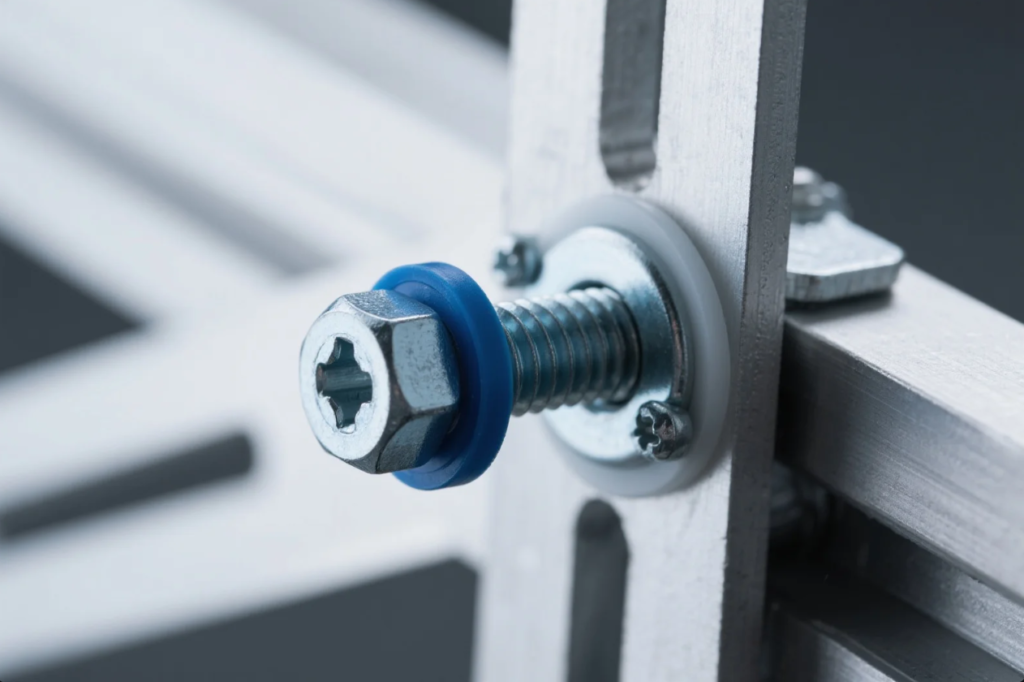

- Use nylon washers or plastic bushings to separate metals

- Apply anti-seize compound on threads

- Seal fasteners with marine-grade silicone

- Avoid ponding water around screw sites

Prime’s marine fasteners come with optional insulation packs, washers, and waterproof coatings for field-ready installation.

What Screws Are Compatible with Aluminium in Saltwater?

Saltwater accelerates electrochemical reactions and demands the highest level of material compatibility.

The most compatible screws for aluminum in marine settings are 316 stainless, anodized aluminum, and plastic-coated variants. Avoid dissimilar metals unless electrically isolated.

Galvanic Compatibility in Marine Conditions

| Screw Material | Saltwater Rating | Compatibility Notes |

|---|---|---|

| 316 Stainless Steel | Excellent | Ideal with insulation in aluminum hulls |

| Anodized Aluminum | Good | Perfect match, minimal risk |

| Coated Steel | Moderate | Not ideal for direct saltwater exposure |

| Brass/Copper | Poor | Highly reactive with aluminum—avoid |

| Plain Steel | Very Poor | Rusts rapidly, unsafe in marine use |

Learn more about galvanic series in seawater.

Marine Fastening Best Practices for Aluminum Hulls

Installing marine fasteners on aluminum boats isn’t just about screw selection—it’s about proper drilling, sealing, and isolating.

Step-by-Step Best Practice

- Mark and Pre-Drill: Use sharp cobalt or titanium bits

- Deburr Holes: Prevent raised edges or misfit

- Apply Sealant: Use marine silicone to block moisture

- Insert Nylon Washer: Electrically isolate metals

- Tighten with Care: Use torque-controlled drivers

- Recheck After 1 Week: Compensate for thermal cycling

We also recommend torque mapping critical mounting points, especially for hull penetrations and engine mounts.

FAQs

Q1: Can I use regular stainless screws on my boat trailer or hull?

A: No. Use 316-grade stainless only. 304 or 302 may corrode in coastal environments.

Q2: Are rubber washers enough to prevent corrosion?

A: Rubber helps, but nylon or plastic isolators are better for long-term use.

Q3: Should I apply thread locker on marine screws?

A: Yes, especially for parts exposed to vibration. Use marine-safe thread lockers.

Q4: Can I use aluminum rivets instead of screws?

A: Yes, but only if the rivets and hull materials match chemically.

Q5: What’s the lead time for Prime’s marine fastener kits?

A: Standard kits ship within 3–5 days; custom kits are available in 7–10.

Conclusion

Securing hardware to an aluminum boat demands more than basic screw knowledge. Choose marine-grade fasteners, isolate dissimilar metals, and use waterproofing methods to extend service life.

👉 Looking for marine-grade screws for aluminum boats?

📌 Visit: https://primecustomparts.com

📧 Contact us: [email protected]

We supply ISO-certified fasteners, corrosion-tested assemblies, and global support to boat builders and marine OEMs.

More Marine Engineering Resources

- Galvanic Corrosion in Boats – BoatUS

- 316 vs 304 Stainless – Marlin Steel

- Naval Fastener Guidelines – US Navy Tech Manual

Prepared by Shandong Prime International Trade Co., Ltd. — Trusted aluminum and marine fastener supplier since 1993.