Why are welders in high demand?

Welding is the hidden force behind global manufacturing—but skilled welders are getting harder to find.

Why are welders in high demand? It’s because of aging workforces, rising industrial needs, and fewer young people entering the trade.

In this article, we’ll answer this question from every angle. Whether you’re sourcing parts or outsourcing production, knowing why welders are in high demand will help you avoid delays and choose better partners.

Do welders make \$100 an hour?

Many people ask: Why are welders in high demand? One reason is the pay.

Some welders earn \$100/hour, but usually in specialized, high-risk environments like offshore rigs or nuclear plants.

Who earns top-dollar in welding?

While entry-level welders in most factories earn \$20–30/hour, certain roles pay far more. Underwater welders, industrial shutdown crews, and pipeline welders often work under extreme conditions. According to Indeed, top contractors do reach \$80–100/hour.

This wage potential is one reason why welders are in high demand—especially for jobs requiring extreme precision or risk.

Is there really a shortage of welders?

Yes. If you’re still wondering why are welders in high demand, here’s another key reason—there simply aren’t enough of them.

The U.S. alone may need over 400,000 new welders by 2027, according to the American Welding Society.

Why the labor gap exists

Older welders are retiring. Fewer people choose trades. Training programs are closing. Meanwhile, infrastructure projects keep growing. That’s exactly why welders are in high demand around the world.

Countries experiencing a welding labor gap

| Country | Status | Notes |

|---|---|---|

| USA | Severe shortage | High pay, urgent hiring across industries |

| Australia | Critical need | Mining, rail, and naval projects |

| Germany | High demand | Metalworking and automotive sectors |

| Canada | Moderate shortage | Oil pipelines and energy-related demand |

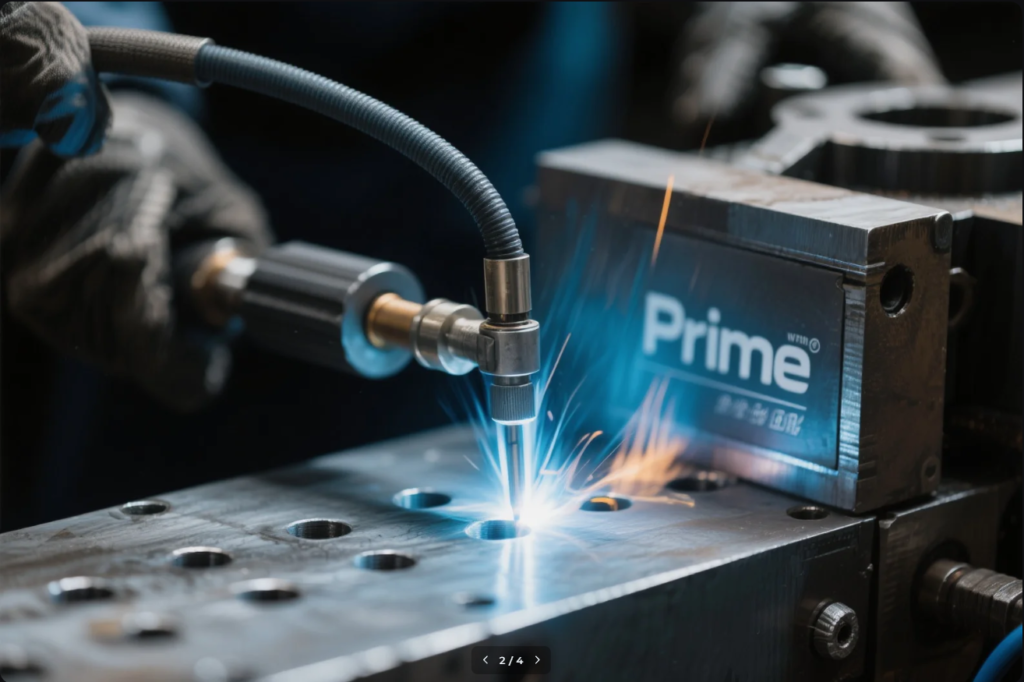

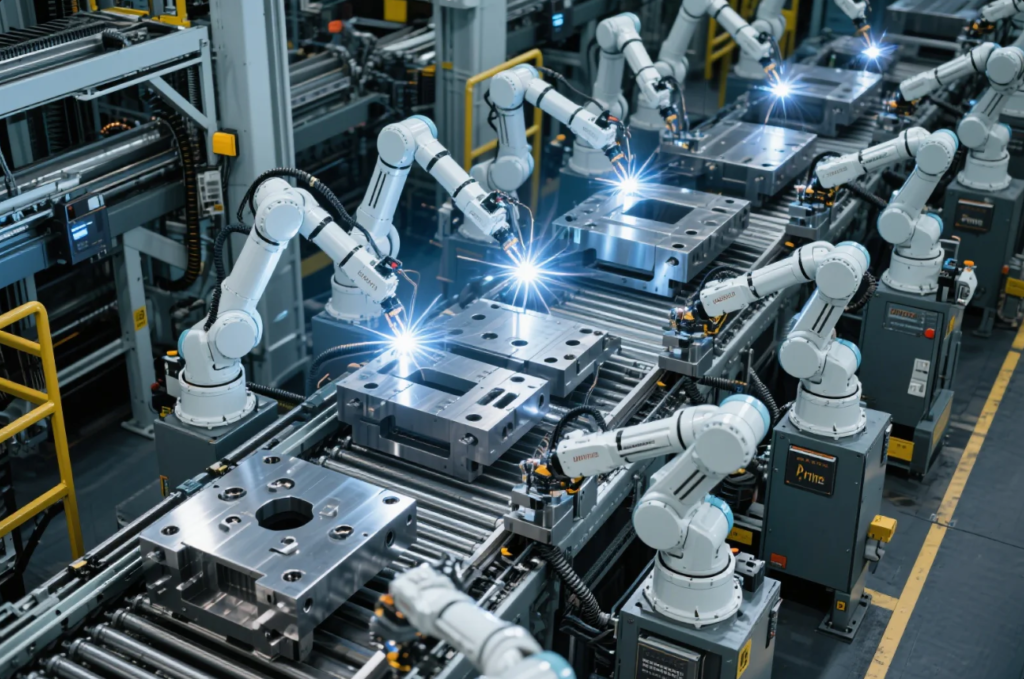

At Prime, we combat this issue through in-house training, robotic welding systems, and global recruitment—so your orders stay on schedule.

Why is the welding industry growing?

Still asking yourself why are welders in high demand? It’s because welding is essential to every major industry.

Welding demand is rising due to infrastructure upgrades, renewable energy, defense projects, and global industrialization.

More industries, more welds

From solar energy systems to military equipment, everything needs welding. When these industries grow, the demand for welders grows too—which answers again: Why are welders in high demand?

Growth sectors driving welding demand

| Industry | Role of Welding |

|---|---|

| Renewable Energy | Wind towers, solar structures |

| Aerospace & Defense | Aircraft frames, missile parts |

| Automotive | Frames, exhaust systems, custom EVs |

| Heavy Machinery | Chassis, tracks, enclosures |

Prime supports all these sectors with ISO-certified welding, from single custom parts to large industrial runs.

Why does everyone want to be a welder?

Why are welders in high demand? Another angle is—more people want in, and for good reason.

Welding offers job security, hands-on work, and high earning potential with relatively low training costs.

Blue collar is back

Welders are proud of their craft. And more young people are realizing that trades can offer freedom, income, and creativity. That’s another layer in answering: Why are welders in high demand? Because it’s becoming a popular career again—while supply still lags behind.

Reasons more people choose welding

| Advantage | Details |

|---|---|

| Fast Career Start | 6–12 month trade programs |

| Strong Demand | Global shortage creates security |

| Creative Problem Solving | Hands-on, non-repetitive work |

| High Salary Potential | \$60K–\$120K/year achievable |

At Prime, we support welding education and hire from local training schools to grow the next generation of talent.

FAQs

Q1: Why are welders in high demand today?

Aging workforce, growing industries, and limited new talent entering the field.

Q2: How do welding shortages affect buyers like me?

Delays, increased labor cost, and limited availability unless you work with prepared suppliers.

Q3: Is automation solving the welder shortage?

Partially. But complex parts and small batches still need human welders.

Q4: Can Prime manage high-volume welding projects?

Yes. We operate 10 production lines and mix robotic and manual welding.

Q5: Do you offer certified welding?

Absolutely. We meet ISO 9001 standards and provide full inspection reports.

Conclusion

Why are welders in high demand? Because they’re essential—and increasingly rare. Choosing suppliers with certified in-house welders protects your timeline and quality.

Contact Us

Looking for a reliable partner for custom welding, precision CNC parts, or ISO-certified fabrication?

✅ Over 20 years of industry experience

✅ In-house welders & robotic welding lines

✅ Stable delivery and strict quality inspection

🔗 Website: https://primecustomparts.com/

📧 Email: [email protected]

We offer free consultations, fast response, and full technical support.

Contact Prime today to get your custom welded parts project started.