Why Custom Metal Molds Are Critical for High-Precision Manufacturing in 2025?

As tolerances shrink and demand for miniaturized components grows, generic molds fall short. Manufacturers face rising defects and inefficiency.

Custom metal molds meet the demands of high-precision production in 2025—supporting miniaturization, automation, and zero-defect output.

This article explores what molds are, how they differ from casting, and why customized tooling is a non-negotiable for precision industries.

What is mold in the manufacturing process?

A mold is a precisely engineered tool used to form material into a desired shape under heat, pressure, or injection.

In manufacturing, molds are used to produce parts consistently with accurate dimensions and surface finishes.

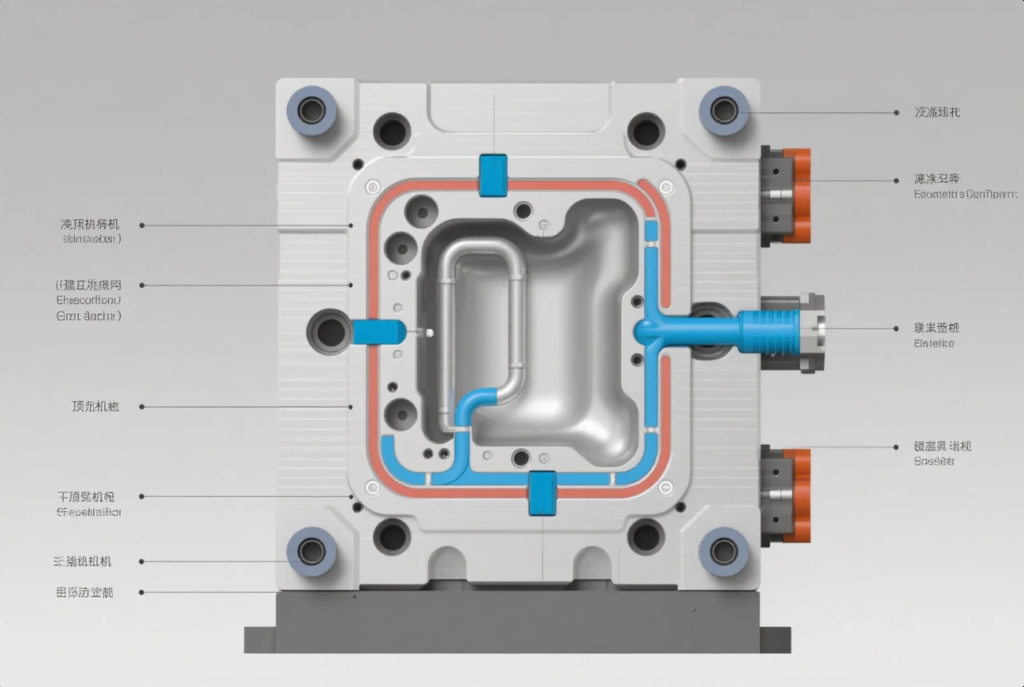

Mold Functions in Production

| Mold Component | Role |

|---|---|

| Cavity/Core Inserts | Define the final part geometry |

| Cooling System | Controls part solidification time |

| Gate System | Directs material into mold cavity |

| Ejector Mechanism | Releases finished part without damage |

Molds are essential for mass production in plastic, metal, ceramic, and composite industries. Learn more from Wikipedia – Molding Process and Autodesk Mold Design Overview.

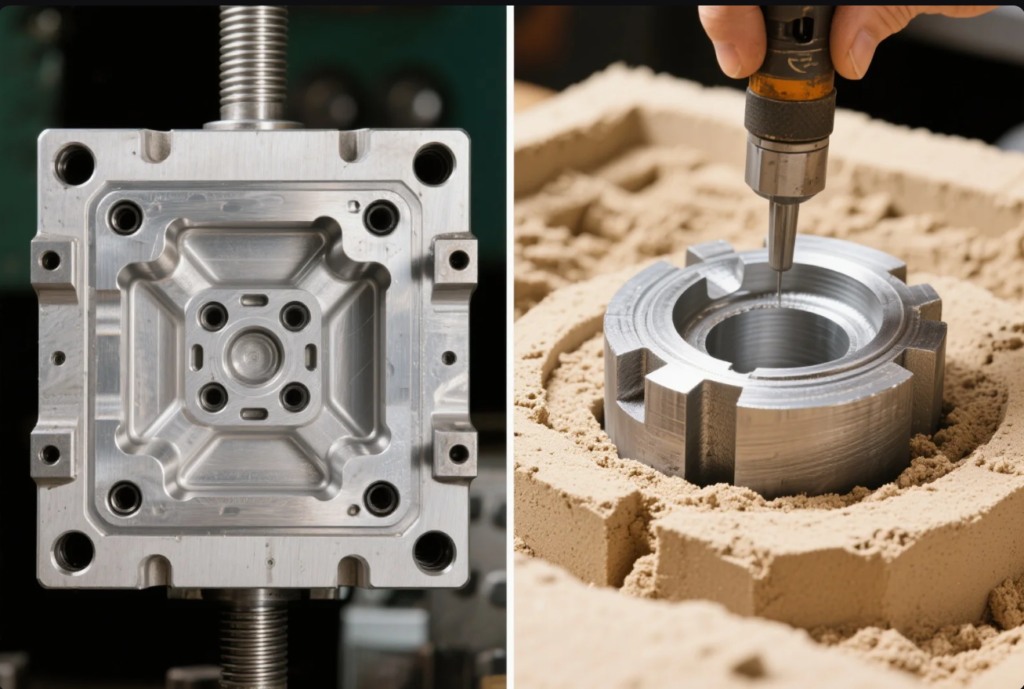

What is the difference between mold and cast manufacturing?

The terms "molding" and "casting" are often used interchangeably, but the processes and tooling are different.

Molding uses pressure to shape material inside a mold, while casting involves pouring molten material into a cavity where it solidifies.

Key Differences Between Molding and Casting

| Feature | Molding | Casting |

|---|---|---|

| Material State | Solid or semi-solid | Fully molten |

| Tooling | Precision mold with ejectors | Open or closed cavity molds |

| Pressure Involved | High pressure injection/press | Low-pressure pouring |

| Surface Finish | Fine (Ra < 0.8 µm) | Often rough, needs post-processing |

Compare further at Engineering Product Design: Molding vs Casting and Reliance Foundry.

What is mold tooling?

Mold tooling includes all components used to shape and form materials into parts—this is the core of any molding process.

Tooling encompasses the cavity/core, base, inserts, sliders, cooling, and ejection systems, all built to exacting specs.

Essential Elements of Mold Tooling

| Tooling Component | Function |

|---|---|

| Mold Base | Structural frame, supports all elements |

| Core/Cavity | Defines part shape and tolerances |

| Sliders/Lifters | Forms side details, undercuts |

| Ejector Pins/Plates | Part removal without damage |

| Cooling/Venting | Temperature control, avoids sink marks |

For further reading, visit Thomasnet – Mold Tooling Types and ToolingU-SME Training.

What is mold design and manufacturing?

Mold design and manufacturing refer to the complete process of conceptualizing, engineering, and fabricating a mold ready for mass production.

Design includes CAD modeling, DFM evaluation, material selection, and cooling analysis. Manufacturing covers CNC, EDM, polishing, and assembly.

Step-by-Step Mold Development

- CAD Modeling – Based on part geometry and shrinkage

- DFM Review – Detects warping, undercuts, ejection risks

- Material Selection – Tailored to part volume and precision

- CAM Programming – For high-accuracy CNC machining

- Mold Assembly – With test shot validation

- Final Debugging – T1/T2 optimization and delivery

We follow this workflow at Prime for every custom project. Learn from Xometry – Mold Design Guide and Modern Machine Shop – Mold Engineering.

FAQs

1. What steel grades do you use?

We use P20, H13, NAK80, and 420SS, depending on part type and production volume.

2. How long does a mold last?

P20 lasts \~300,000 shots. H13 and stainless molds: over 1 million cycles with good maintenance.

3. What file formats do you accept?

STEP, IGES, Parasolid, STL, DXF, SolidWorks, and AutoCAD.

4. Do you provide moldflow or cooling simulation?

Yes. We provide Moldex3D and CADMOULD reports for every new mold.

5. Do you support international shipping?

Absolutely. We ship globally with ISPM-15 packaging and CE/ISO documentation.

Conclusion

In 2025, precision molds are non-negotiable. At Prime, we deliver ISO-certified metal molds for demanding industries worldwide.

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let’s mold your next breakthrough—with accuracy, speed, and reliability.