Why Do Industrial Buyers Prefer Custom Metal Forgings for Precision Components?

Industrial buyers often face unstable quality, missed deadlines, and lack of customization1 when sourcing metal parts2 for demanding industrial projects.

Custom metal forgings deliver unmatched precision, mechanical strength, and design flexibility for industrial buyers worldwide. These solutions meet the most rigorous requirements of automotive, heavy equipment, oil and gas, and energy industries. When you choose a reliable supplier1, you gain better cost control, consistent quality, and long-term supply security.

Choosing custom forging solutions helps industrial buyers solve practical problems that off-the-shelf components can’t address. I have worked in this industry for over two decades, so I know how much difference a dependable forging partner1 can make. Continue reading to discover why custom metal forgings2 are the preferred choice for high-performance industrial components and how to select the right supplier for your needs.

Why Choose Custom Metal Forgings for High‑Performance Components?

Industrial projects often demand higher performance1, tighter tolerances, and extended service life2. Many standard parts fail to meet these requirements, leading to costly downtime and maintenance.

Custom metal forgings deliver superior strength, precise dimensions, and tailored designs1 for every industrial sector. Clients specify sizes, alloys, and surface finishes to ensure the final part fits their exact needs.

Based on my past sourcing experience, I have seen how forgings outperform castings1 and stamped parts, especially for safety-critical or high-stress environments. Forged parts handle shock, vibration, and load far better than other manufacturing methods. They last longer and resist failure, reducing your maintenance costs and boosting productivity.

Key Advantages Table: Forging vs. Casting vs. Stamping

| Property | Custom Forging1 | Casting | Stamping |

|---|---|---|---|

| Strength | Excellent | Moderate | Limited |

| Tolerance | Tight | Moderate | Loose |

| Impact Resistance2 | High | Moderate | Low |

| Fatigue Life | Extended | Moderate | Short |

| Material Density | Very High | Medium | Low |

| Customization | Flexible | Moderate | Low |

What Problems Do Forgings Solve?

- Eliminates breakage under heavy loads

- Avoids unpredictable wear and tear

- Reduces risk of early failure1

- Handles extreme working environments2

I remember a project where a global mining company switched to custom-forged couplings1 after repeated casting failures. The result was a 70% drop in unplanned maintenance2 and nearly zero downtime.

Main Industries Using Custom Forgings

- Automotive and heavy truck manufacturing1

- Oil and gas equipment

- Renewable energy and power plants2

- Railways and aerospace

- Construction machinery

Custom forgings1 are essential whenever you need strength, durability, and reliable long-term performance2.

Materials & Alloys: What Metals Work Best for Precision Forging?

Selecting the right material1 is crucial for your project’s success. Many buyers get overwhelmed by the range of alloys2 and specifications. Every application needs the best balance of performance, machinability, and cost.

Prime offers custom forgings1 in carbon steel2, alloy steel, stainless steel, aluminum, copper, and special alloys. Each metal offers unique benefits for specific industries and working conditions.

Typical Forging Materials and Their Applications

| Alloy Type | Key Properties | Main Industrial Uses |

|---|---|---|

| Carbon Steel1 | High strength, cost-effective | Gears, shafts, construction parts |

| Alloy Steel | Wear, fatigue resistance | Axles, crankshafts, machine parts |

| Stainless Steel2 | Corrosion, heat resistance | Valves, pumps, chemical equipment |

| Aluminum Alloys | Lightweight, conductive | Aerospace, electric, transport |

| Copper Alloys | Conductivity, formability | Busbars, heat exchangers, electrical |

| Special Alloys | Extreme environments | Turbine components, defense |

Selecting the Right Alloy: What Should Buyers Consider?

- Mechanical requirements1: Do you need more strength or flexibility?

- Environment: Will the part face moisture, heat, or chemicals?

- Machinability: Do you need easy post-forging processing?

-

Cost2: Is price a main concern for your business?

For example, I helped an automotive client select 42CrMo alloy steel1 for transmission gears due to its balance of strength and fatigue resistance. For a food equipment supplier, we chose 316L stainless steel2 for its anti-corrosion properties.

Comparison Table: Alloy Types for Common Applications

| Application Area | Recommended Alloy | Why Choose It? |

|---|---|---|

| Mining Drills | Alloy Steel1 | Toughness and wear resistance |

| Marine Fittings | Stainless Steel2 | Saltwater and corrosion protection |

| High-Speed Shafts | Carbon Steel | Cost-effective with high durability |

| Lightweight Brackets | Aluminum Alloy | Reduces weight, easy to machine |

| High-Conductivity Bars | Copper Alloy | Excellent electrical properties |

When you partner with Prime, our engineers work with you to select the most suitable metal or alloy1, considering every aspect of your application, operating environment2, and budget.

Leading Industry Resources and Directories

As you consider suppliers, it’s vital to compare services and capabilities from leading industry directories. To research the best custom metal forging manufacturers1 and precision forging companies2, you can visit:

- www.made-in-china.com

- www.globalsources.com

- www.alibaba.com

- www.thomasnet.com

- www.directindustry.com

- www.indiamart.com

- www.exportersindia.com

- www.ec21.com

- www.tradekey.com

- www.hktdc.com

- www.ferret.com.au

- www.b2bmetal.eu

These platforms allow you to compare factory certifications, process capabilities, and client reviews for custom forging suppliers1 and ISO certified forging manufacturers2 worldwide.

Quality Control: How Do We Ensure ISO‑Certified Forging Standards?

Reliable buyers know that strict quality control1 is the foundation of every successful project2. You want every shipment to meet your specs, with zero surprises.

Prime’s quality management starts with raw materials and continues through every production step. As an ISO 9001-certified1 forging supplier, we guarantee full traceability2, rigorous testing, and reliable documentation for every batch.

Full-Spectrum Quality Control: What Do We Check?

- Incoming material inspection with certification review1

- In-process control: temperature, pressure, and dimensional checks

- Final inspection: 3D scanning, hardness, and surface quality

- Destructive and non-destructive testing as required

- Complete batch traceability and digital records2

How Does Prime Keep Quality Consistent?

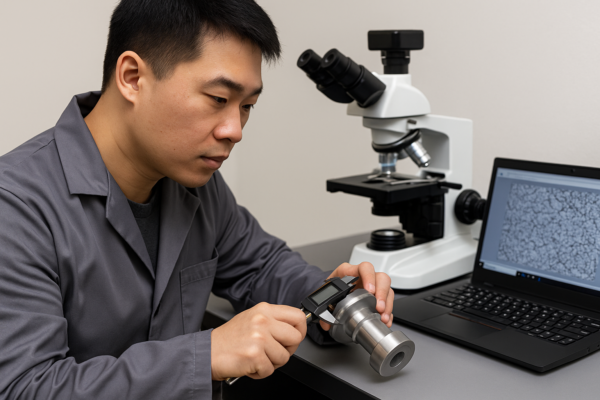

I have walked through dozens of supplier factories. At Prime, I see automated sensors1 monitoring every forging press. Engineers document process parameters for each lot. Our lab runs microstructure checks and hardness tests. We perform 100% visual inspection before packing. Prime also shares full inspection reports2, so clients always know what they are getting.

Quality Control Table: From Raw Material to Finished Part

| QC Stage | Method/Equipment | Outcome |

|---|---|---|

| Raw Material Check1 | Spectrometer, certificate | Alloy and composition confirmed |

| Forging Process | Temperature, pressure sensor | Accurate grain structure |

| Machining Inspection | Calipers, CMM, gauges | Exact dimensions |

| Surface Quality | Visual, roughness test | Defect-free finish |

| Final Testing2 | UT/MT/Hardness | Reliable, certifiable quality |

What Certifications Matter?

- ISO 9001:20151 – Quality management system

- ISO/TS 169492 – Automotive industry standards

- EN10204 3.1/3.2 – Material test certificates

Buyers often ask for certifications1 with each shipment. At Prime, we attach certificates, test reports, and traceability sheets2 with every order. This saves you time during audits and inspections.

How to Request a Quote: What’s the Process from Drawing to Delivery?

Getting started with a custom forging order1 should not be difficult. I have streamlined hundreds of sourcing projects2 by using a step-by-step approach.

To request a quote, simply send your drawing and requirements to Prime. Our engineers review your needs, suggest the best materials, and issue a detailed quotation1. After your approval, we manage sample production, mass manufacturing2, and delivery.

The Step-by-Step Quoting and Delivery Process

- Send Technical Drawings: CAD, PDF, or even hand sketches are acceptable.

- Share Key Requirements: Include materials, quantity, tolerances, and surface finish.

- Engineering Review1: Prime’s technical team checks for feasibility and suggests improvements.

- Quotation: Receive a detailed quote, including costs, lead time, and logistics options.

- Sample Production: Get prototype samples for testing and approval.

- Order Confirmation: Once samples pass, mass production begins.

- QC and Packaging: Each part undergoes full inspection and secure export-standard packaging.

- Shipping: Choose sea, air, or courier logistics based on urgency and budget.

- After-Sales Support2: Prime remains responsive for any technical or shipping questions.

Sample Timelines Table

| Step | Typical Timeframe | Key Notes |

|---|---|---|

| Engineering Review1 | 1-2 business days | Fast feedback with clear drawings |

| Quotation Issued | 24-48 hours | Details all inclusions |

| Prototype Sample | 7-15 days | Varies by complexity |

| Mass Production2 | 20-35 days | Larger or urgent orders possible |

| Delivery | 1-4 weeks (global) | Based on location and logistics |

Pro Tips for Buyers

- Always provide clear drawings and material specs.

- Ask for packing and QC photos1 before shipping.

- Confirm all certifications and paperwork requirements at the start.

- Communicate your delivery deadlines2—Prime is known for reliable on-time shipments.

I have learned the importance of clear, ongoing communication1 throughout the entire order process. Prime provides dedicated account managers2 for each project, ensuring buyers receive updates at every stage.

Other Useful B2B Sourcing Sites

For additional supplier verification1, reviews, and news about the custom metal forging2 industry, buyers should also consider:

- www.b2brazil.com

- www.europages.com

- www.taiwantrade.com

- www.tradeindia.com

- www.forgingsupplier.com

- www.machinebuilding.net

- www.engineering360.com

- www.exporthub.com

- www.go4worldbusiness.com

- www.manufacturer.com

- www.kompass.com

These directories help compare more custom forging suppliers1, discover new market trends, and verify global certifications2.

FAQs: Your Questions About Custom Metal Forgings Answered

1. What are the benefits of custom metal forgings over cast or machined parts?

Custom metal forgings1 offer superior strength, reliability, and performance. They are less prone to defects and have a more uniform grain structure2, making them ideal for critical industrial applications.

2. Can Prime produce small or complex-shaped forgings?

Yes. Prime specializes in precision forgings1, including small, intricate shapes and large heavy-duty components. We use advanced dies and CNC machining2 to achieve complex geometries.

3. How do you guarantee on-time delivery?

Prime operates 10 production lines and uses digital order management systems1 to ensure each project stays on schedule. We share progress updates2, packing photos, and shipping notifications throughout the process.

4. What industries do you serve?

We serve automotive, oil and gas, power generation, railway, mining, construction, and many other heavy industries1. Prime’s clients include global OEMs2 and leading distributors.

5. Can you support urgent or low-volume orders?

Yes, Prime supports urgent, prototype, and low-volume orders1. We are flexible in production planning and can adjust schedules for priority shipments.

6. Do you provide product certifications?

All orders come with ISO certificates1, material test reports2, and traceability records. Additional third-party inspections are available upon request.

7. What payment and shipping methods do you accept?

We accept T/T, L/C, and other secure payment terms. Shipments can go by sea, air, or courier based on client preference and urgency.

8. How do you ensure export packaging meets requirements?

Prime uses heavy-duty wooden crates1, moisture barriers, and protective wrapping to safeguard every shipment. Packaging complies with international export standards2 and client specifications.

9. How do I start my order?

Just email your drawing and project requirements to [email protected] or visit our website at https://primecustomparts.com/. Our team responds within 24 hours.

10. Can you help optimize my part design for forging?

Absolutely. Our engineers offer design-for-manufacturability (DFM) reviews and technical consulting to help you reduce costs and improve performance.

Conclusion

Custom metal forgings give buyers strength, precision, and trust in every project. Prime delivers ISO-certified quality and reliable on-time service for every order. Contact us today through https://primecustomparts.com/ or email us at [email protected] for a free consultation, expert quotation, and a custom solution tailored to your business. Let’s create success together with fast delivery and consistent quality you can rely on.

-

Explore this link to understand how heavy-duty wooden crates enhance shipment safety and compliance. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about international export standards to ensure your packaging meets global requirements. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩