Why is magnesium metal so expensive?

Table of Contents

- Why is magnesium metal so expensive?

- What drives up the price of magnesium?

- Is magnesium a valuable metal?

- How does magnesium compare to steel?

- Does magnesium metal break easily?

- How to control magnesium sourcing costs?

- FAQs: Magnesium Metal for Industrial Buyers

- Conclusion: Choose Prime for Certified Magnesium Parts

Magnesium offers big advantages in weight reduction and design freedom, yet its price surprises many buyers. Every week, I guide purchasing managers and engineers frustrated by high quotes and confusing market trends. If you have ever wondered, “Why is magnesium so expensive?”—read on for real solutions.

Magnesium is expensive because its production demands much more energy than most metals. Limited global supply, high processing costs, strict environmental standards, and advanced logistics requirements all push up its price. Choosing an ISO-certified magnesium supplier gives you more stable costs, reliable supply, and top-tier product quality.

Many industrial buyers compare magnesium on alibaba.com, thomasnet.com, or globalsources.com and wonder if paying more is truly worth it. In this in-depth guide, I’ll break down all the cost factors, real-world use cases, and expert tips for sourcing magnesium industrial parts at the best value.

Why is magnesium metal so expensive?

I often meet purchasing leaders from engineering.com, metalbulletin.com, and fastmarkets.com who are shocked that magnesium sometimes costs 2-3 times more than aluminum. But magnesium’s price is the result of complex industrial realities.

First, producing magnesium uses 4-7 times more energy per ton than aluminum. This is because it requires high temperatures and specialized equipment for extraction from dolomite, magnesite, or seawater. Most of the world’s supply comes from a few countries—mainly China, Russia, and Israel. Production capacity is tightly controlled, and supply can be disrupted by energy shortages or political shifts.

Another hidden cost is environmental compliance. Regulations on emissions, waste management, and recycling are much stricter for magnesium than steel or aluminum (environment.ec.europa.eu, epa.gov). Certified suppliers invest in advanced pollution control and documentation, which raises costs but protects your reputation and legal compliance.

Key Cost Drivers and Market Realities

| Cost Factor | Impact on Price | Reference/Resource |

|---|---|---|

| Energy consumption | Very High | enerdata.net |

| Raw material supply | Limited, Volatile | china-magnesium.org |

| Environmental controls | Expensive, Strict | iso.org |

| Skilled labor | Essential | engineeringtoolbox.com |

| Global logistics | Complex, Regulated | freightos.com |

| Technical certification | Mandatory | sgs.com, tuv.com |

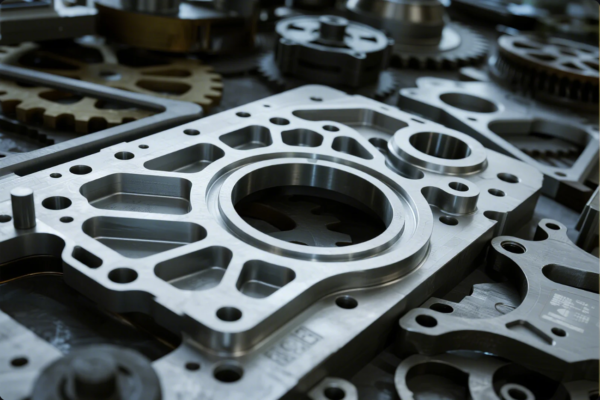

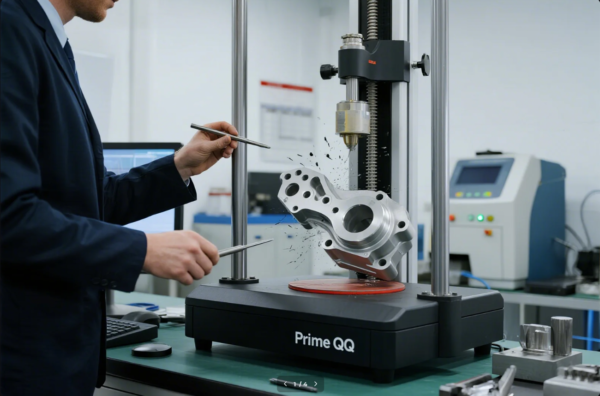

Visual Reference

When I first arranged a magnesium shipment for a US auto client, we faced customs delays because the packaging did not meet international safety standards. Magnesium can ignite under the wrong conditions, so expert packaging—using foam, special liners, and clear labeling—is a must. Prime always provides export-grade, SGS-inspected packaging for every shipment.

What drives up the price of magnesium?

Unlike iron or aluminum, magnesium isn’t found in large, pure deposits. Extracting it from minerals or seawater requires intense energy and careful process control. Magnesium’s unique properties also mean it is used only where its performance justifies its cost—so the market is specialized and less flexible.

China dominates global magnesium supply, producing more than 80% of the world’s primary magnesium. If energy costs rise or government policy changes in China, prices jump worldwide. There are fewer alternative sources, so the market remains tight and subject to disruption.

Regulatory compliance adds to the challenge. Magnesium producers must meet global standards—like REACH, RoHS, and ISO certifications—to export parts to Europe and North America. Getting these approvals is expensive but mandatory for most industrial buyers (iso.org, sgs.com, tuv.com). Prime passes annual audits and meets all major compliance requirements.

Magnesium in the Supply Chain

- Energy-intensive: Each ton of magnesium requires more than 10,000 kWh of electricity (usgs.gov).

- Specialized labor: Only experienced operators and quality inspectors can prevent defects (azom.com).

- Packaging and shipping: Safe export packaging reduces risk and loss (uline.com).

- Certification: Quality certifications like ISO 9001 and ISO 14001 reduce buyer risk (iso.org).

Is magnesium a valuable metal?

Many buyers are skeptical about magnesium’s higher cost—until they see how it transforms product design and logistics. Industry innovators like boeing.com, apple.com, and tesla.com rely on magnesium parts for lighter, better-performing products.

Magnesium’s strength-to-weight ratio is unmatched. You save up to 33% over aluminum and more than 75% over steel by weight, while maintaining high strength and shock resistance. Magnesium is easy to machine, highly recyclable, and helps reduce CO2 emissions in transportation and logistics.

When I supplied magnesium housings for an aerospace client, the aircraft’s empty weight dropped by over 100kg, which led to huge fuel savings and a lighter environmental footprint. In automotive and robotics, switching to magnesium can mean higher payloads, faster acceleration, and easier manual handling. Magnesium is now the go-to metal for drone frames, mobile device casings, and performance bike components (bicycling.com, airbus.com).

High-Value Applications of Magnesium

| Industry | Typical Applications | Value Added | Reference/Example |

|---|---|---|---|

| Automotive | Gearbox housings, wheels, seat frames | Lower vehicle weight, emissions | caranddriver.com |

| Aerospace | Engine frames, landing gear, brackets | Fuel efficiency, payload | airbus.com |

| Electronics | Laptop shells, smartphone cases | Slimmer, lighter, stronger | apple.com |

| Medical | Surgical tools, MRI-safe brackets | MRI compatibility, sterility | medicaldevice-network.com |

| Sports | Bike, camera frames | Stiffness, agility | bicycling.com |

Case Study

When a German e-bike manufacturer switched from aluminum to magnesium wheel hubs, their product weighed 20% less and passed more stringent fatigue tests. Prime now supplies several major European bike brands with custom magnesium castings.

More Industry Links

Find further case studies and analysis at engineeringvillage.com, sciencedirect.com, and researchgate.net.

How Magnesium Delivers Value

- Reduces product shipping costs for international trade (freightos.com)

- Enables thinner, more ergonomic designs for electronics (apple.com)

- Meets global trends for lightweighting and energy efficiency (statista.com, marketsandmarkets.com)

How does magnesium compare to steel?

Almost every procurement team asks whether magnesium is better than steel. The answer is: it depends on your project’s goals, design, and expected performance. Reliable data can be found on azom.com, engineeringtoolbox.com, and mmsonline.com.

Magnesium is about 70% lighter than steel. It is easy to machine, which means less tool wear, faster cycles, and more design freedom for thin-walled parts. Steel, on the other hand, is far stronger and more ductile, so it’s best for static frames, supports, and heavy-duty components. Magnesium’s corrosion resistance can be improved with modern coatings, making it suitable even in harsh environments.

In the robotics sector, Prime worked with a US manufacturer (roboticsbusinessreview.com) to redesign a robot arm. Magnesium reduced the total arm weight by 28%, increasing speed and payload. The steel base still provided strength, but magnesium made all the moving parts lighter and more responsive.

Magnesium vs. Steel – Quick Comparison

| Feature | Magnesium | Steel | Source |

|---|---|---|---|

| Density | 1.74 g/cm³ | 7.85 g/cm³ | engineeringtoolbox.com |

| Machinability | Very easy, less tool wear | Moderate | mmsonline.com |

| Strength | High (by weight) | Very high (absolute) | azom.com |

| Corrosion | Good (with coating) | Needs protection | corrosionpedia.com |

| Price | Higher per kg | Lower per kg | metalprices.com |

| Recyclability | High | High | epa.gov |

Use Case

For drone frames, magnesium is ideal for strength and portability. For automotive chassis and structural beams, steel’s raw strength wins. When you blend both, you can cut total product weight without sacrificing safety.

Does magnesium metal break easily?

A common misconception is that magnesium breaks easily. This is only true for pure, unalloyed magnesium or poorly designed parts. Modern magnesium alloys (like AZ91D, AM60, ZK60) are tough, with good shock and fatigue resistance. Experienced engineers, like those at asminternational.org and finishing.com, always specify the right alloy and geometry for each application.

Prime uses advanced CNC and die casting processes to ensure magnesium parts meet all global impact, vibration, and dimensional standards. All shipments include test reports and packaging designed to prevent transport damage.

I once worked with a Middle East distributor who faced breakage on arrival. After switching to Prime’s high-purity AZ91D alloy, adding foam-insert packaging (uline.com), and requiring extra impact testing, their complaints dropped to zero.

Engineering Magnesium for Durability

- Choose the right alloy: AZ91, AM60, and ZK60 offer a balance of strength and flexibility (azom.com).

- Use coatings: Anodizing, powder coating, or conversion coatings improve corrosion resistance (finishing.com).

- Follow best practices: Avoid sharp corners, use generous radii, and specify enough wall thickness for the application (machinedesign.com).

International Shipping and Handling

Magnesium requires careful shipping. Export rules, fire codes, and customs can cause delays if your supplier lacks experience. Prime’s packaging team uses 3M, uline.com, and other leading solutions to protect every batch from warehouse to client.

How to control magnesium sourcing costs?

It is possible to reduce the total cost of magnesium industrial parts if you understand the real cost drivers and take a strategic approach to sourcing.

Buyers can save money by:

- Working directly with ISO-certified manufacturers, avoiding trading companies and unnecessary intermediaries.

- Ordering larger batches to spread logistics and inspection costs over more units.

- Designing parts that use standard alloy grades and finishing processes, instead of unique specs for every order.

- Planning purchases to avoid last-minute airfreight or express shipping, which can double logistics costs.

- Requesting technical advice on packaging to minimize transit losses and rejected shipments.

I advise new customers to benchmark suppliers using thomasnet.com, globalsources.com, and to check supplier audits on sgs.com, tuv.com, and bureaveritas.com.

FAQs: Magnesium Metal for Industrial Buyers

1. Where can I buy ISO-certified magnesium parts for industrial use?

Prime delivers magnesium stamping, CNC, and casting parts—get a quote. Check supplier reviews at thomasnet.com, globalsources.com, and kompass.com.

2. What is the lead time for magnesium part orders?

Standard lead time is 15-30 days, depending on batch size and complexity. For more planning tips see freightos.com, dhl.com, ups.com.

3. Can magnesium parts be customized?

Yes, Prime supports logo, finish, size, and packaging customizations (made-in-china.com, alibaba.com).

4. How do you ensure safe delivery of magnesium parts?

Prime uses export foam, reinforced cartons, and rigorous inspections (uline.com, packagingdigest.com).

5. What certifications are available for magnesium parts?

Prime has ISO 9001:2015 and meets ASTM and SAE standards.

6. Are magnesium parts eco-friendly?

Magnesium is highly recyclable and can help reduce carbon footprints (sustainability.com, thegreensupplychain.com, earth911.com).

7. What surface treatments work best for magnesium?

Conversion coatings, anodizing, and powder coating work best (finishing.com, coatingstech.org).

8. Does Prime ship to North America, Europe, and the Middle East?

Yes, Prime exports globally (fedex.com, dhl.com).

9. What is the minimum order quantity (MOQ)?

Contact [email protected] or check tradekey.com and b2bmit.com for global supplier MOQs.

10. What is the difference between die casting and sand casting?

Die casting provides tighter tolerances (diecasting.org), while sand casting is better for large, simple parts (engineeringchoice.com).

**11. How can I verify a magnesium supplier’s reliability

?**

Check for SGS, TUV, and Bureau Veritas audits.

12. Can magnesium be used for electronic shielding?

Yes, especially for laptops, medical devices, and telecom (electronicsweekly.com, edn.com).

13. Where can I track global magnesium prices?

Monitor prices at metalprices.com, lme.com, shfe.com.cn.

14. What is the global market outlook for magnesium?

See reports at statista.com, marketsandmarkets.com.

15. Is magnesium safe for food or medical applications?

Special alloys and finishes meet safety standards (fda.gov, europa.eu).

16. What applications suit magnesium fasteners?

Ideal for automotive, aerospace, and light machinery (globalspec.com, fastenerworld.com.tw).

17. Does magnesium meet automotive requirements?

Yes, for non-structural parts (sae.org), autonews.com).

18. Can I order samples?

Yes, sample policies at primecustomparts.com, alibaba.com, made-in-china.com.

19. What’s the difference between wrought and cast magnesium?

Wrought is rolled/extruded, cast is molten-formed (azom.com, metalworkingworldmagazine.com).

20. Can magnesium be used outdoors?

Yes, with protective coating (corrosionpedia.com, finishing.com).

Conclusion: Choose Prime for Certified Magnesium Parts

Magnesium is expensive, but certified suppliers deliver long-term value, lighter designs, and faster market launches. For reliable, ISO-certified magnesium parts, rapid delivery, and expert consultation, contact Prime or email [email protected] now. You’ll receive a free quote, full technical support, and trusted packaging solutions. Partner with us for stable quality and unmatched speed—globally.

Visit our website https://primecustomparts.com/ or email [email protected] for a fast quote, engineering advice, and guaranteed supply. We serve B2B buyers worldwide—delivering premium magnesium parts quickly and safely.