Why is Stamping Used?

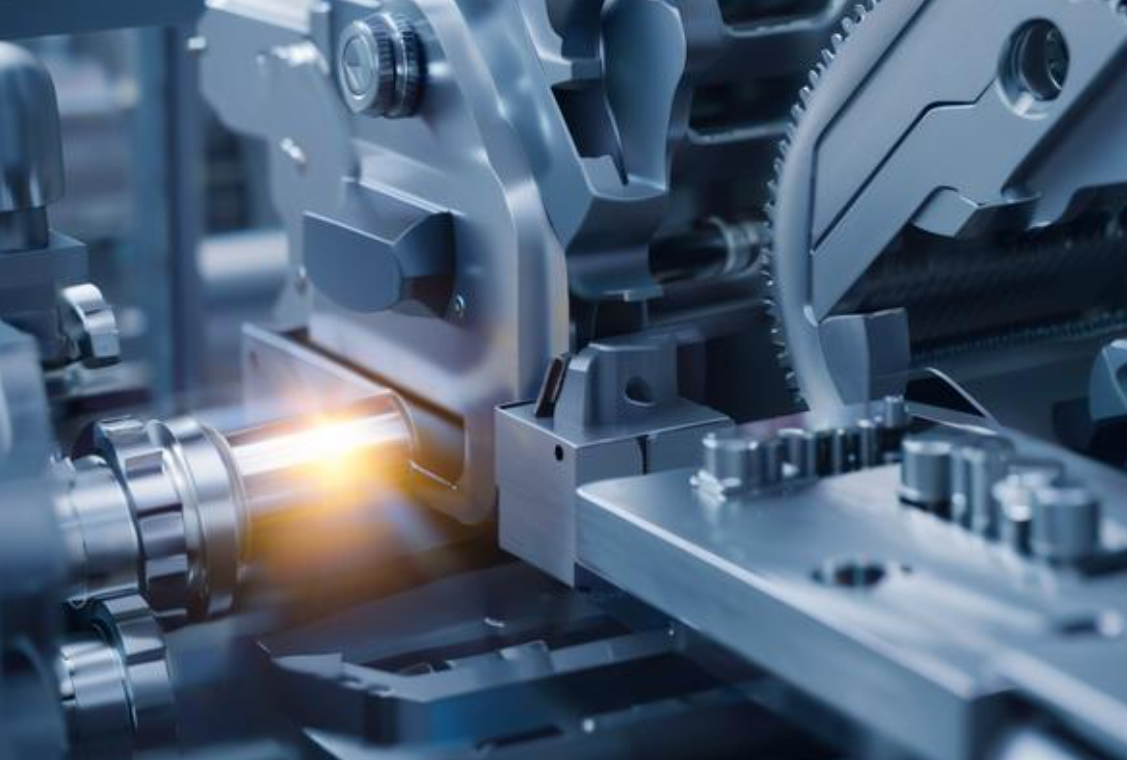

Have you ever wondered why stamping is such a critical process in manufacturing? Let’s explore the reasons behind its widespread use and its advantages.

Stamping is used to shape metal sheets into precise components efficiently, offering high precision, repeatability, and cost-effectiveness, making it essential in industries like automotive, electronics, and aerospace.

Keep reading to understand why stamping is a go-to method in manufacturing and its benefits for various industries.

What Makes Stamping Essential?

Why is stamping so integral to manufacturing? Its ability to produce high-quality, precise metal components quickly and reliably sets it apart.

Stamping is essential because it allows for the mass production of precise metal parts with consistent quality, ensuring efficiency and reliability in manufacturing processes.

The Precision of Stamping

Stamping is known for its precision, making it ideal for creating intricate metal parts. Here’s how it works:

- Design: Engineers draft detailed blueprints.

- Die Creation: Custom molds (dies) are designed.

- Stamping: Metal sheets are shaped by the die in a press.

Advantages of Precision

- Consistency: Ensures each part meets exact specifications.

- Complexity: Allows for detailed and intricate designs.

- Efficiency: Reduces the need for additional finishing work.

Why Choose Stamping Over Other Methods?

Why is stamping preferred over other manufacturing methods? Its unique advantages make it indispensable.

Stamping is chosen for its ability to produce large volumes of metal components quickly, with minimal waste and high repeatability, making it cost-effective and efficient.

Key Benefits of Stamping

- Cost-Effectiveness: Reduces material waste and labor costs.

- Speed: Produces components faster than many other methods.

- Versatility: Can handle a wide range of metal types and thicknesses.

Comparison with Other Methods

| Method | Advantages | Limitations |

|---|---|---|

| Stamping | High speed, precision, cost-effective | Limited to metal sheets |

| Molding | Suitable for complex shapes | Higher initial tooling costs |

| Machining | High precision for small batches | Slower and more expensive for large volumes |

Applications of Stamping in Different Industries

Where is stamping most commonly used? Its versatility makes it essential in various sectors.

Stamping is widely used in industries like automotive, electronics, and aerospace for creating high-precision metal components that meet stringent quality standards.

Stamping in the Automotive Industry

The automotive sector heavily relies on stamping for various parts.

- Body Panels: Precision shaping of car doors, hoods, and fenders.

- Engine Components: Producing durable, high-quality engine parts.

Benefits for Automotive Manufacturing

- Durability: Stamped parts are strong and long-lasting.

- Efficiency: High-speed production meets demand.

Stamping in Electronics

Why is stamping crucial for electronics? Its precision is unmatched.

- Connectors: Creating precise, reliable electronic connectors.

- Shielding Components: Producing effective EMI/RFI shielding.

Precision in Electronics

- Miniaturization: Allows for tiny, intricate parts.

- Consistency: Ensures reliability in electronic devices.

Stamping in Aerospace

In aerospace, stamping ensures high-quality components for safety and performance.

- Structural Components: Creating strong, lightweight parts.

- Fasteners: Producing reliable, durable fasteners.

Aerospace Standards

- Quality: Meets stringent safety and performance standards.

- Reliability: Ensures components perform under extreme conditions.

Economic Advantages of Stamping

How does stamping benefit manufacturers economically? Its cost-effectiveness and efficiency are key.

Stamping provides significant economic advantages by reducing production costs, minimizing material waste, and enabling high-volume production, making it a preferred choice for manufacturers.

Cost Efficiency

- Reduced Labor Costs: Automated processes lower labor expenses.

- Material Savings: Minimal waste due to precision.

Examples of Cost Savings

- Automotive Industry: High-volume production reduces per-unit costs.

- Electronics: Efficient production of small, intricate parts cuts costs.

Speed and Volume

- High-Speed Production: Rapid creation of components.

- Mass Production: Ability to produce large quantities quickly.

Impact on Business

- Lower Costs: Faster production reduces overall costs.

- Market Competitiveness: High volumes enable competitive pricing.

How Prime Utilizes Stamping Effectively

Why does Prime excel in stamping? Our expertise and technology set us apart.

Prime leverages advanced stamping techniques to deliver high-quality, precision metal components, ensuring efficiency and reliability for our clients across various industries.

Our Approach to Stamping

- Customization: Tailoring solutions to meet specific client needs.

- Quality Control: Ensuring each part meets strict quality standards.

- Innovation: Using cutting-edge technology for superior results.

Commitment to Excellence

- Experience: Over two decades of expertise in stamping.

- Standards: Adherence to ISO quality certifications.

Case Studies

- Automotive Components: Supplying high-quality stamped parts for leading car manufacturers.

- Electronics Solutions: Delivering precision stamped connectors for global electronics companies.

Success Stories

- Client Feedback: Positive testimonials highlighting reliability and quality.

- Industry Recognition: Awards and certifications for excellence in stamping.

Conclusion

Stamping is essential for producing precise, high-quality metal components efficiently. Prime excels in this process, providing tailored solutions for diverse industrial needs.