Why Precision Metal Parts Are Essential in Medical and Electronics Fields?

Precision isn’t optional in medicine and electronics—it’s a matter of function, safety, and performance. From implants to circuit boards, precision metal components keep life-saving tools and digital systems working flawlessly.

This article explores what precision metals are, why they matter in healthcare and electronics, and how Prime supports global OEMs with certified, high-tolerance components.

What Is a Precision Metal?

Precision metals are defined by their tight tolerances, usually within ±0.005 mm, and are essential in critical systems. These metals—often used in medical device manufacturing—must perform under tight spatial constraints and extreme environmental conditions.

They’re common in:

- Surgical implants and instruments

- Miniaturized sensor housing

- Robotic surgical assemblies

- Microfluidic diagnostic chips

Prime achieves this through advanced machining methods like Swiss turning and 5-axis micro-milling, backed by optical inspections capable of verifying sub-micron features.

What Is the Most Suitable Metal for Medical Devices?

According to ISO 10993, materials used in the human body must meet strict biocompatibility standards. Titanium (Ti-6Al-4V) stands out as the top choice due to its light weight, non-reactive surface, and strength.

Other certified metals include:

- 316L stainless steel (non-magnetic, corrosion-resistant)

- Cobalt-chromium for load-bearing stents

- Nitinol for shape-memory vascular implants

All of Prime’s sourced materials come with EN 10204 3.1 certificates and meet ASTM F138 or ISO 5832-1 for surgical applications.

How Are Metals Used in the Medical Field?

Metals serve various roles beyond implants, including structural supports for diagnostic imaging equipment and autoclave-resistant lab instruments. According to PubMed studies, titanium and stainless steel remain the safest for prolonged exposure within biological systems.

Common uses:

- MRI frame assemblies

- Endoscopic tool shafts

- Bone fixation systems

- Centrifuge racks and fixtures

Prime supports these applications with electropolished, burr-free surfaces that pass sterilization compatibility tests including high-temperature steam and ethylene oxide gas.

What Materials Are Used in Medical Devices?

While polymers and ceramics are present, metals are preferred for load, conductivity, and radiopacity. Tantalum, for instance, is ideal for X-ray markers due to its high density, while aluminum is commonly used for diagnostic device casings where heat dissipation is critical.

| Material | Function in Devices |

|---|---|

| Titanium | Long-term implant, bone integration |

| Stainless 316L | Surgical tools, reusable systems |

| Aluminum 6061 | Lightweight shells, diagnostic housing |

| Copper Alloys | EMI shielding, conductivity |

| Tantalum | X-ray contrast markers |

Prime follows material validation protocols as recommended by FDA medical device classifications and supports customer-specific standards such as CE/MDR.

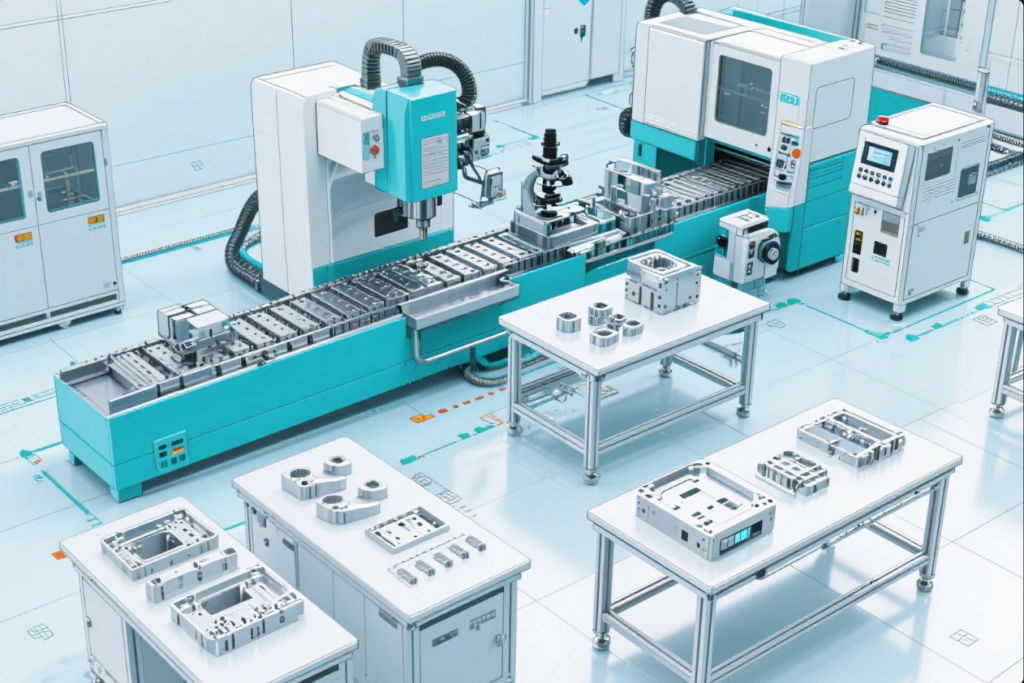

Manufacturing Process of Precision Medical and Electronic Parts

Manufacturing precision parts begins with DFM (Design for Manufacturability) reviews based on ISO-compliant files. We then create prototypes using multi-axis machining or micro-stamping, ensuring all critical dimensions conform to Engineering360’s standards for medical machining.

Prime’s 6-step flow:

- Drawing review and material check

- Prototype with sample inspection

- Mass production using CNC/Swiss turning

- Electropolishing, anodizing, passivation

- CMM/vision inspection with <5µm resolution

- Cleanroom packaging with UDI labeling

Every batch is tracked with operator ID, time stamp, and test data. Compliance includes ISO 9001 and ISO 13485-aligned QA workflows.

Surface Finishing in Medical and Electronics Applications

High-performance finishing enhances not just hygiene, but also device functionality. Prime offers:

- Passivation (ASTM A967) for corrosion resistance

- Electropolishing for smoother surfaces and improved sterilization

- Type II/III anodizing for insulation and biocompatible coloring

- Cu/Ni sputtering for EMI shielding in diagnostic casings

These treatments align with standards from ASTM F899, ensuring reliability in critical applications.

Packaging & Traceability Standards

To protect delicate medical and electronic components, Prime uses:

- ISO Class 8 cleanroom packaging

- Double-bag vacuum sealing

- ESD-safe trays for electronic modules

- QR/UDI/lot codes laser-etched or labeled

Packaging also supports compliance with CE, MDR, and UDI standards as outlined by FDA medical device labeling guides.

Project Success Cases

🦴 Orthopedic Trial: 500 Ti6Al4V bone screws delivered with anodized coding. Passed ISO 10993 biocompatibility and cytotoxicity tests.

🔬 EU Lab Project: EMI shielded aluminum shells with sputtered copper interior. Passed all signal strength and CE safety tests.

🇯🇵 Japanese Wearable: Ultra-light 6061 casings with black anodizing and <±0.01 mm tolerances. Passed 1m drop test.

🧪 German Biotech: Microfluidic titanium plates with 0.25 mm channels and electropolished finish. Delivered for a COVID-19 diagnostics system.

FAQs

Q: Can you handle Nitinol and CoCr machining?

Yes, with proper tool paths and cooling strategy.

Q: Are your QA docs traceable to ISO standards?

All QA steps are ISO 9001 and ISO 13485-aligned.

Q: Can you ship sterile-ready parts?

Yes, we provide vacuum-packaging for gamma/ETO sterilization.

Q: Do you offer UDI/lot tracking?

Yes, with etched or labeled UDI formats per FDA guidelines.

Conclusion

Precision metals power tomorrow’s medicine and electronics. By working with the right certified supplier, you ensure your product performs where it matters most—in real surgeries, labs, and lives.

📧 Contact Prime at [email protected]

🌐 Visit https://primecustomparts.com for your free consultation, quote, or design evaluation.

Let Prime bring your ideas to life—with precision you can trust.