Top 5 Benefits of Using Custom Metal Molds in Manufacturing Operations: Why Precision Tooling Drives Industrial Efficiency?

Inconsistent parts waste time, money, and trust.

This article highlights the top 5 benefits of using custom metal molds in industrial manufacturing. From higher precision and repeatability to reduced cycle times and lower defect rates, custom tooling transforms operational performance.

Engineers and buyers alike will learn why tailored molds are essential to competitive and scalable production.

What are the advantages and disadvantages of mold?

Every mold offers trade-offs—but custom molds maximize output for the right product mix.

Advantages of molds include tight tolerances, fast cycle times, and repeatable part quality. Disadvantages may include high upfront costs and limited flexibility for rapid design changes. However, custom molds reduce waste and downtime over the long term.

Pros and Cons Overview

| Advantages | Disadvantages |

|---|---|

| Consistent part quality | High initial tooling cost |

| Fast production cycles | Longer lead time (design to build) |

| Suitable for high-volume runs | Design revisions can be expensive |

| Enables automation | Limited to compatible materials |

Prime minimizes mold cost by offering early-stage DFM and modular tool inserts.

For more, see Protolabs’ analysis and SyBridge Technologies’ insights.

What is mold design and manufacturing?

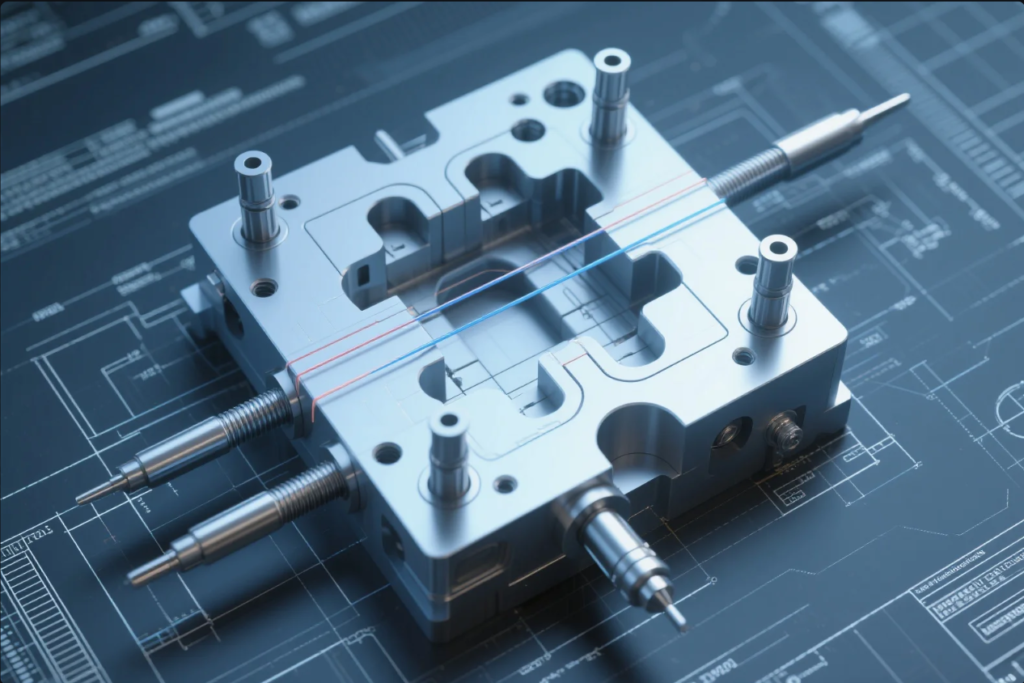

Mold design is the process of transforming part requirements into precision tooling systems.

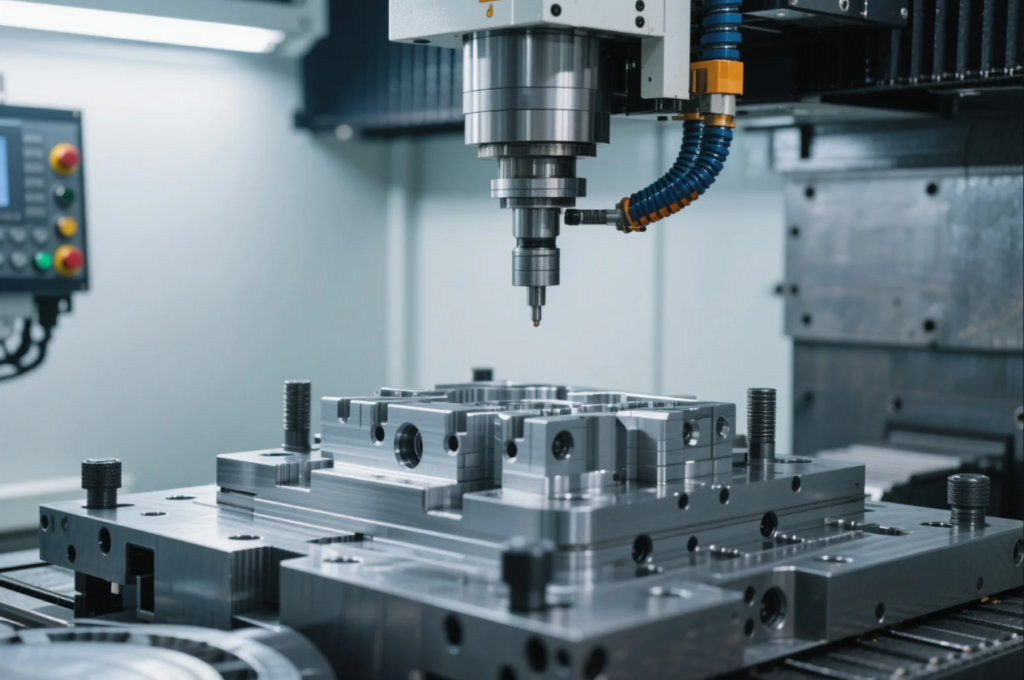

It involves defining cavity layout, selecting mold steel, configuring cooling channels, and building ejector systems. Mold manufacturing includes CNC milling, EDM, grinding, and polishing to create the final tooling components.

Design and Build Steps

- 3D modeling with DFM review

- Tool steel selection

- Core/cavity layout and gating

- CAM programming and machining

- Polishing, QC, and mold trial

At Prime, we provide both design and build services with ISO 9001-certified QA and trial runs.

See how 3ERP outlines the mold-making process and Extreme Molding discusses mold manufacturing intricacies.

What are Moulds in manufacturing?

Molds are the backbone of mass manufacturing.

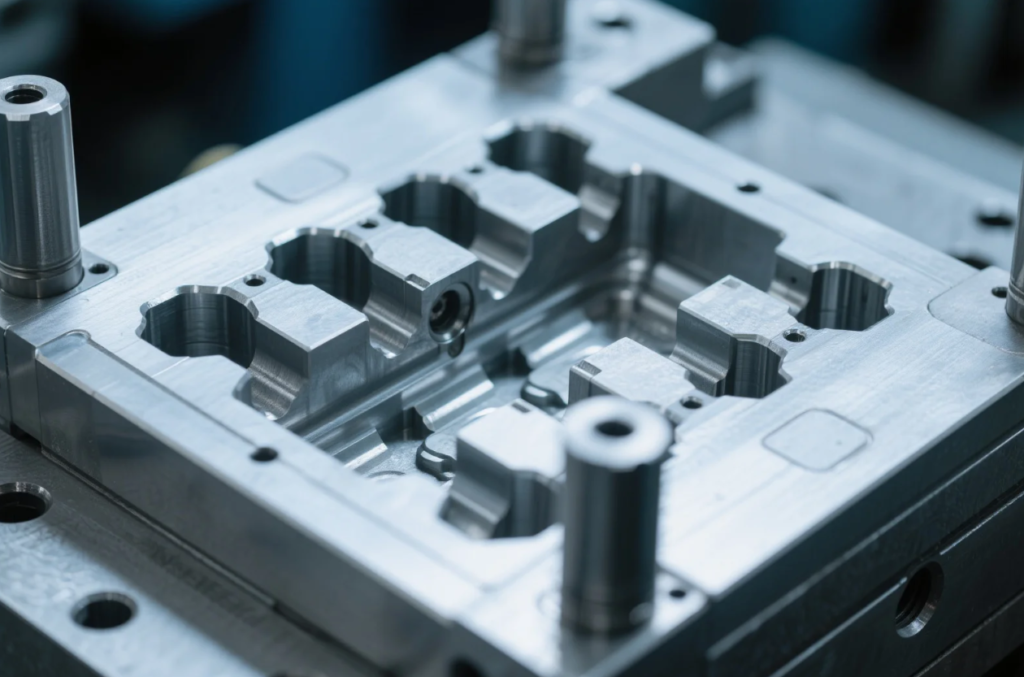

A mold is a hollow tool used to shape material into a specific form. In metal parts manufacturing, molds are used for die casting, stamping, and metal injection molding (MIM). They allow repeatable shaping under pressure and heat.

Types of Manufacturing Molds

| Mold Type | Use Case |

|---|---|

| Injection Mold | MIM or plastic parts |

| Stamping Die | Flat sheet metal forming |

| Die Casting Mold | Aluminum or zinc casting |

| Hot Runner Mold | For continuous, fast cycles |

Molds improve speed, accuracy, and uniformity across all manufacturing sectors.

Explore mold uses via Britannica – Mold Technology and Wikipedia – Molding Process.

What are the industrial importance of molds?

Industries rely on molds to maintain production flow and product quality.

Molds are crucial for efficient manufacturing. They enable consistent production at scale, reduce per-part costs, and support automation. In sectors like automotive, aerospace, and electronics, molds ensure compliance with tight tolerance standards.

Mold Benefits in Industry

| Sector | Mold Role |

|---|---|

| Automotive | High-speed production of complex parts |

| Medical | Precision for implants/tools |

| Consumer | Cost-effective mass production |

| Aerospace | Lightweight, high-strength components |

At Prime, we produce molds that meet strict export packaging, tolerance, and lead time demands.

For further reading, refer to Shunhao’s insights and Liang Long’s overview.

FAQs

Q1: Are custom molds worth the cost?

A1: Yes—especially for high-volume or precision parts. ROI improves with every production cycle.

Q2: How long does it take to build a custom mold?

A2: On average, 2–5 weeks depending on complexity. Prime also offers rush programs.

Q3: What file formats does Prime accept for mold design?

A3: STEP, IGES, Parasolid, and native formats from SolidWorks and UG NX.

Q4: Can molds be reused across projects?

A4: In many cases yes, via modular inserts and family mold layouts.

Q5: Do you provide trial runs before mold shipment?

A5: Always. Prime includes QC reports and part trials for approval.

Contact Information

Upgrade your operations with long-lasting, custom-built molds.

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

What we offer:

- Custom mold design and manufacturing

- Stamping, MIM, and die cast mold options

- ISO-certified QA and fast global shipping

- DFM and cost-saving design suggestions

Boost your production efficiency—start with the right mold.

Contact Prime now for a free consultation, DFM review, and cost quote.