Will 7018 Weld Aluminum?

Trying to use the wrong welding rod on aluminum leads to cracked joints, wasted time, and failed parts.

No, 7018 rods are designed for steel—they cannot weld aluminum effectively or safely.

Let’s look at why aluminum requires different electrodes, and how to choose the right method.

Can I use 7018 on aluminum?

It’s a common mistake—but using 7018 on aluminum doesn’t work.

No, 7018 welding rods are not compatible with aluminum—they’re specifically made for carbon and low-alloy steel.

Why 7018 won’t work on aluminum

7018 rods contain an iron powder flux coating designed to stabilize arcs and prevent cracking in steel welds. But aluminum:

- Has different melting behavior

- Lacks compatible metallurgical bonding with steel electrodes

- Requires non-ferrous fillers like E4043

I’ve seen clients try 7018 on aluminum and end up with weak, contaminated welds that flake off under pressure.

Table: 7018 Rod Compatibility

| Base Metal | Weldability with 7018 | Notes |

|---|---|---|

| Carbon Steel | Excellent | Designed for structural welds |

| Low-Alloy Steel | Good | Strong joints |

| Stainless Steel | Poor | Use stainless-specific rod |

| Aluminum | Not weldable | Requires aluminum electrode |

At Prime, we only use 7018 for steel components. For aluminum, we switch to MIG or TIG with proper filler rods.

What metal can 7018 weld?

7018 is a go-to rod in heavy industry—for steel only.

7018 rods are ideal for welding mild steel, low-alloy steel, and structural steel components.

Where 7018 shines

This low-hydrogen electrode produces smooth, ductile welds with great mechanical properties. It’s commonly used in:

- Construction beams and columns

- Pressure vessels and bridges

- Machinery frames and piping

It offers excellent crack resistance and is compliant with many structural welding codes (e.g., AWS D1.1).

Table: Common Uses for 7018

| Industry | Application | Why 7018 Works Well |

|---|---|---|

| Construction | I-beams, structural frames | Strong, low-slag welds |

| Manufacturing | Machinery, brackets | Toughness, durability |

| Pipelines | Seam welds on thick pipe | High tensile strength |

| Automotive (steel) | Chassis repairs | Smooth arc, minimal spatter |

At Prime, we use 7018 extensively for heavy-duty welded steel components—but we never cross-use it on non-ferrous metals like aluminum.

Can I weld aluminum with 6011?

Some believe any stick rod can weld anything—but that’s not true.

No, 6011 rods are not made for aluminum—they’re for steel and iron-based metals.

Why 6011 doesn’t work for aluminum

The 6011 rod excels at cutting through dirty, rusty steel with deep penetration. But its flux is completely incompatible with aluminum’s chemistry and oxide layer.

Welding aluminum with 6011 will:

- Fail to form a proper bond

- Result in severe porosity

- Risk electrode contamination

Table: 6011 Rod vs. Aluminum

| Property | 6011 on Steel | 6011 on Aluminum |

|---|---|---|

| Arc Stability | Good | Poor |

| Bond Strength | High | None |

| Surface Compatibility | Excellent | Incompatible |

For stick welding aluminum, special aluminum electrodes like E4043 are required—but even then, performance is limited.

At Prime, we guide clients away from stick welding aluminum altogether and offer TIG/MIG alternatives for better strength and cleaner welds.

Can you use an arc welder to weld aluminum?

Yes—but only with specific tools, preparation, and limits.

You can arc weld aluminum, but only using aluminum-specific electrodes and careful technique.

When arc welding aluminum works (barely)

While possible in theory, stick welding aluminum is:

- Hard to control

- Prone to slag, porosity, and cracking

- Unreliable for critical components

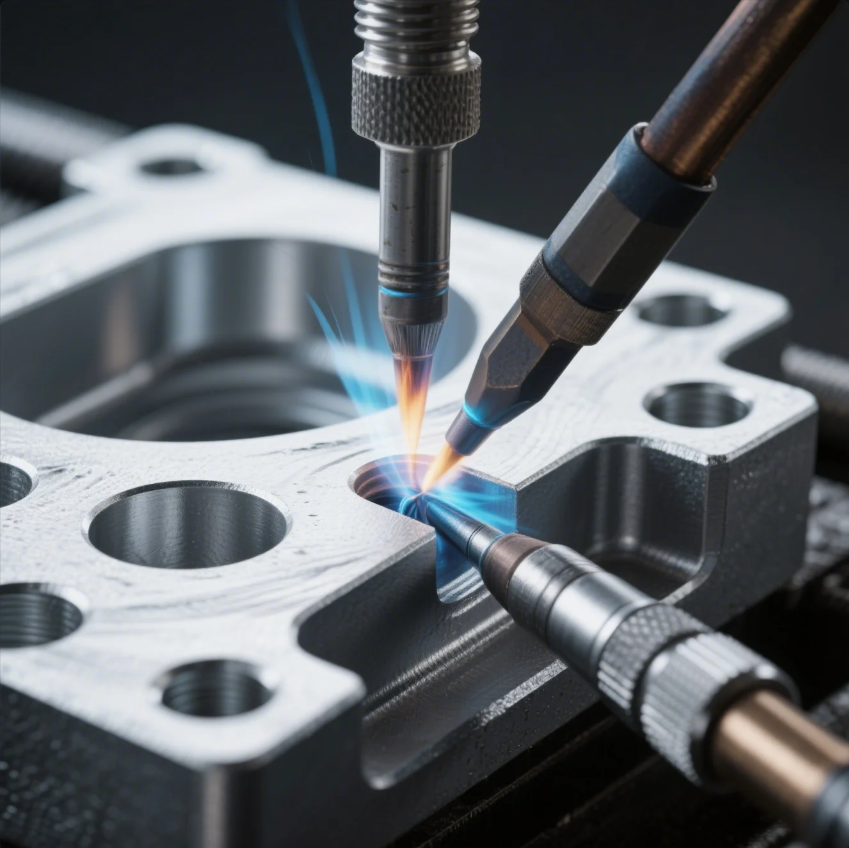

If using a stick welder, you must:

- Use E4043 or E5356 aluminum electrodes

- Weld at high amperage with fast travel

- Clean the surface aggressively to remove oxide

Even then, results are usually inferior to MIG or TIG welding, especially for thinner sections or aesthetic applications.

Table: Welding Aluminum by Process

| Process | Quality | Best For | Notes |

|---|---|---|---|

| Stick (SMAW) | Low | Emergency repair | Limited control, spatter |

| MIG (GMAW) | High | Production, medium parts | Spool gun improves results |

| TIG (GTAW) | Very High | Precision, thin materials | Cleanest weld, most control |

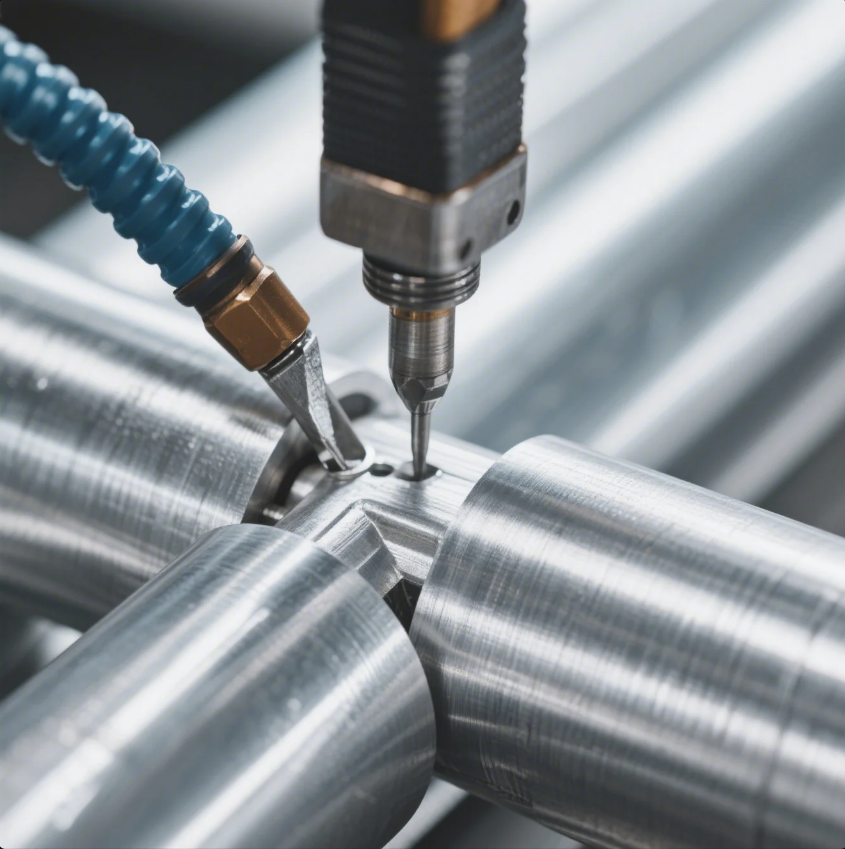

Prime supports clients with custom TIG/MIG aluminum welding services, often including CNC aluminum blanks and fixturing to reduce field issues.

Conclusion

7018 rods are for steel—not aluminum. To weld aluminum, use the right method and the right materials.

Avoid guesswork and weak joints—contact Prime now for expert welding services, proper filler selection, and high-precision aluminum parts.

We provide ISO-certified welding, CNC machining, and global delivery to help your project succeed the first time.

Get your free quote and consultation today.