Will JB Weld Hold Aluminum Together?

Are you struggling to find a robust, cost-effective, and reliable method to join aluminum without welding? You are not alone. In the fast-paced world of manufacturing, sourcing, and engineering, traditional welding is often expensive, slow, or impractical for prototypes and low- to mid-volume orders. Many global procurement managers and engineers now ask: Can industrial adhesives like J-B Weld truly hold aluminum together? The answer is nuanced—success depends on application, part design, and expert execution.

J-B Weld and other industrial epoxies can bond aluminum in many use cases. But results depend on surface prep, application skills, and understanding joint loads. Inconsistent preparation or choosing the wrong adhesive means weak bonds, failed prototypes, and lost business.

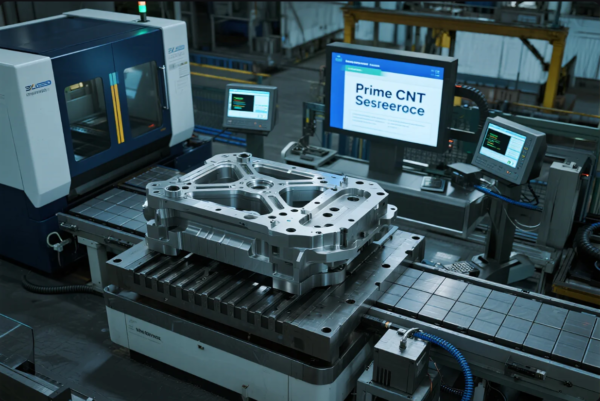

At Prime, our 20+ years of global B2B supply experience have shown: adhesives can work—but only when you control the details. This guide shares real insights for buyers, engineers, and OEMs sourcing custom aluminum, stamping, CNC, and cast parts worldwide.

Table of Contents

- Does J-B Weld Adhere to Aluminum?

- How Do You Bond Aluminum Without Welding?

- Best Epoxies and Adhesives for Aluminum

- How to Prepare Aluminum for Bonding

- Design and Engineering Insights

- Quality, Certification & Compliance

- Packaging & Global Logistics

- Real-World Use Cases & Buyer Scenarios

- Common Mistakes and How to Avoid Them

- FAQs

- Conclusion

- Contact Prime

Does J-B Weld Adhere to Aluminum?

One of the most common questions buyers ask is whether J-B Weld and similar epoxies actually bond to aluminum. The answer: Yes—but only when the aluminum is prepared correctly. Adhesives bond by creating a mechanical grip and a chemical connection at the surface, not by melting metal as with welding.

The science of adhesive bonding is explained in Henkel’s technical literature and validated by TWI Global. Here are the critical factors:

- Remove all oil, oxide, and residue with a solvent like acetone (Loctite’s application guide).

- Sand the surface (80–120 grit) to increase bonding area.

- Apply adhesive immediately after cleaning; aluminum oxide reforms in minutes (Aluminum Association).

Never assume an adhesive joint will fully replace a welded, riveted, or mechanically fastened one—especially in high-vibration, high-load, or heat-exposed applications. As noted in AZO Materials’ expert review, adhesive bonds can outperform mechanical fasteners in shear but are weaker in peel or impact.

How Do You Bond Aluminum Without Welding?

Modern manufacturers are shifting from traditional joining methods to advanced adhesives and mechanical fasteners. Why? Adhesives offer design freedom, low weight, corrosion resistance, and quick assembly—without heat distortion or expensive tooling (3M bonding metals overview).

Your primary options:

- Structural epoxy adhesives: Examples include J-B Weld, 3M Scotch-Weld, Loctite Hysol, and Permabond.

- Acrylic and polyurethane adhesives: For fast cure or flexible bonds (Permatex metal epoxy).

- Double-sided tapes: For lightweight panels or decorative pieces (3M VHB Tape).

- Mechanical fasteners: Use Fastenal’s selection or McMaster-Carr for bolts, screws, and rivets.

Application Table:

| Joining Method | Main Advantages | Limitations | Learn More |

|---|---|---|---|

| Structural Epoxy | Distributes stress, seals, no heat | Lower impact/peel strength | Engineering Toolbox |

| Mechanical Fastener | High load, field repair, removable | Adds weight, needs drilling | ThomasNet |

| 3M VHB Tape | Clean, fast, no cure | Only for panels/light fixtures | 3M VHB Tape |

Best Epoxies and Adhesives for Aluminum

With dozens of brands and formulations, global buyers must choose adhesives based on load requirements, certifications, cure speed, and local availability. The best adhesives are certified by ISO or ASTM, and used by leading manufacturers.

Industry-Proven Options:

- J-B Weld Original: Ideal for field repair, maintenance, and general industrial bonding.

- 3M Scotch-Weld: Used for OEM production; fast curing, high shear strength.

- Loctite Hysol: Industrial-grade; excellent for aluminum, steel, and dissimilar materials.

- Permabond ET500: High viscosity for gap filling; RoHS and REACH compliant.

- Permatex Metal Epoxy: Great for rapid repairs and prototyping.

How to Prepare Aluminum for Bonding

Surface prep is where most adhesive joints fail. No matter how strong the adhesive, if the aluminum isn’t clean and roughened, the joint will not last.

Expert process:

- Degrease: Use acetone or a specialty cleaner (Loctite advice).

- Abrasive prep: Sand with 80–120 grit to bare, bright metal (Henkel surface prep).

- Degrease again: Remove any dust and residue.

- Immediate application: Bond within minutes, as AZOM notes that aluminum oxide reforms fast.

- Clamp: Ensure tight fit and hold during full cure.

Packaging & Global Logistics

Aluminum is easily scratched and oxidized. Prime uses multi-layer export packaging, VCI anti-rust film, and edge protectors—similar to the best practices at ULINE.

For delivery worldwide, we offer sea, air, and rail shipping with full Incoterms transparency (Freightos Incoterms Guide).

Quality, Certification & Compliance

Prime supplies ISO 9001:2015 and RoHS certification with every order. Major clients require batch-level documentation, SGS inspection or Bureau Veritas audit, and full raw material test reports.

Real-World Use Cases & Buyer Scenarios

Rapid Prototyping

A US electronics OEM orders CNC aluminum housings and uses J-B Weld to bond covers during testing.

Medical Device Supplier

European clients require ISO-certified adhesives and RoHS-compliant fasteners.

Automotive Parts Distributor

North American buyers use 3M Scotch-Weld to join aluminum and composite parts.

Industrial Machinery Builder

Combines fasteners and adhesives from Fastenal and McMaster-Carr.

E-commerce Sourcing Manager

Verifies suppliers on Alibaba, ThomasNet, or Global Sources.

Contact Prime

Website: https://primecustomparts.com/

Email: [email protected]