Cylinder Components

The world's leading supplier of metal cylinder parts.

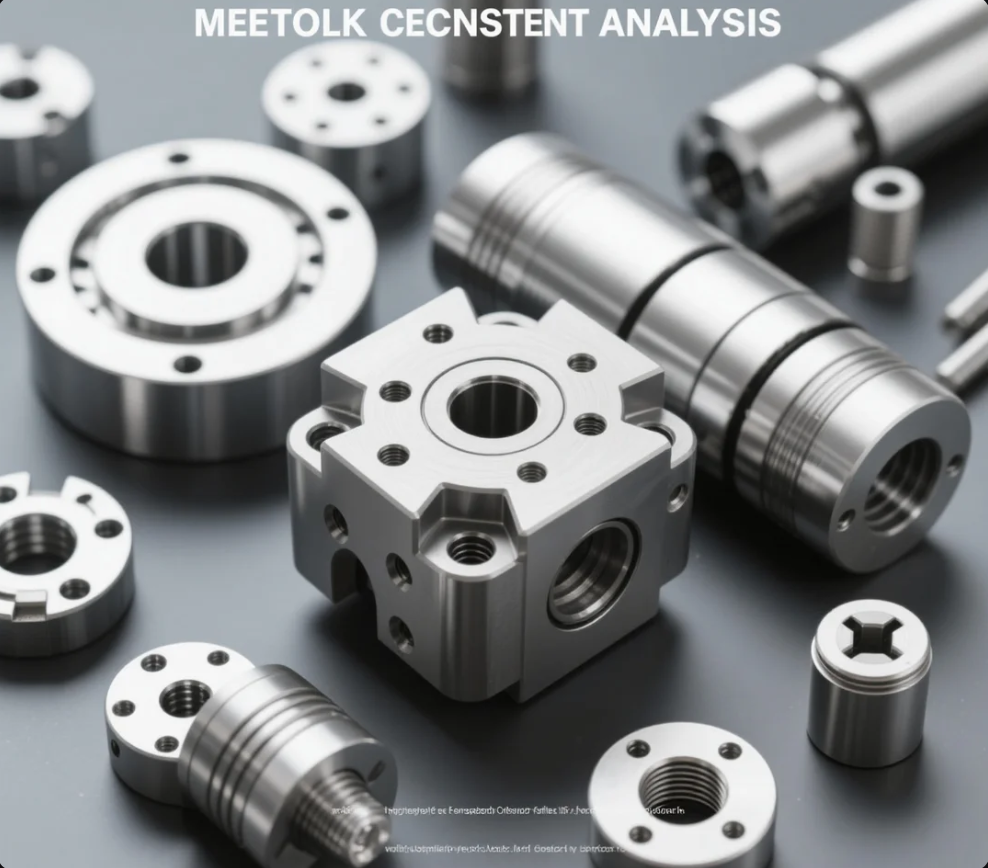

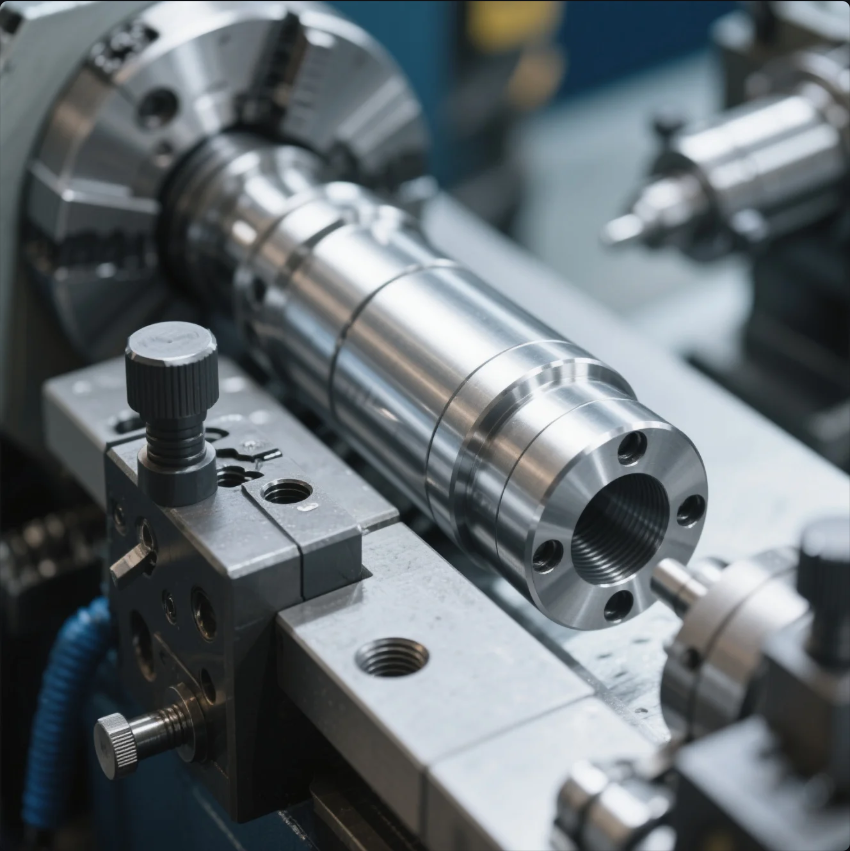

Customized metal cylinder parts

Customized metal cylinder components are indispensable core components in modern industrial equipment, which are widely used in key fields such as hydraulics, pneumatics, energy and machinery manufacturing. We offer customized cylinder solutions through high precision metalworking and casting technology to meet customers’ stringent requirements in terms of structural strength, sealing performance, pressure rating, etc. .

Application fields of customized metal cylinder components

Customized metal cylinder components are widely used in hydraulic and pneumatic systems, automation equipment, engineering machinery, petrochemical industry, rail transit and marine equipment and other key fields, is all kinds of high-voltage drive and execution system of the core component. With excellent pressure resistance, sealing and structural strength, these components can adapt to high load, high frequency, corrosive or harsh working conditions in extreme environments to ensure the stability and safety of equipment operation. We can provide a one-stop customized solution from drawing design to mass delivery to meet the stringent requirements of high-performance cylinder components from customers around the world.

Your trusted expert in the manufacture of metal cylinder parts

In industrial equipment, the stability and sealing performance of cylinder components are directly related to the operation efficiency of the whole machine. With more than 30 years of experience in precision manufacturing, Prime specializes in the production of high-performance metal cylinder components, providing reliable, cost-effective solutions to global customers. All of our products are ISO quality certified to ensure that each cylinder components are durable long-term use test.

As a professional factory in China, Prime has 10 advanced production lines, specializing in manufacturing all kinds of stamping, CNC machining, casting and related structural parts, products are widely exported to North , Europe, the Middle East, Australia and other markets. Our efficient batch delivery capacity and strict quality control, has won the favor of many international buyers.

We provide customized cylinder components in a wide range of sizes and constructions, including custom drawings, brand logos and packaging, to meet the needs of engineering projects and distribution businesses.

Contact us immediately to add lasting power to your product with Prime’s high quality metal cylinder parts!

Stainless steel flexible filling hose for gas cylinder

Use our metal cylinder parts and stainless steel flexible filling hoses to increase the efficiency of your industrial equipment. They have excellent pressure resistance and sealing, widely used in gas transmission, hydraulic system and high pressure container connection and other scenarios, to ensure safe and reliable, long-lasting performance.

LPG Gas Cylinder neck ring

Use our metal cylinder component, the Liquefied petroleum gas cylinder neck ring, to enhance the safety and efficiency of your industrial operations. With excellent structural strength and dimensional accuracy, they are widely used in the manufacture and reuse of gas cylinders to ensure air tightness and long-term reliability.

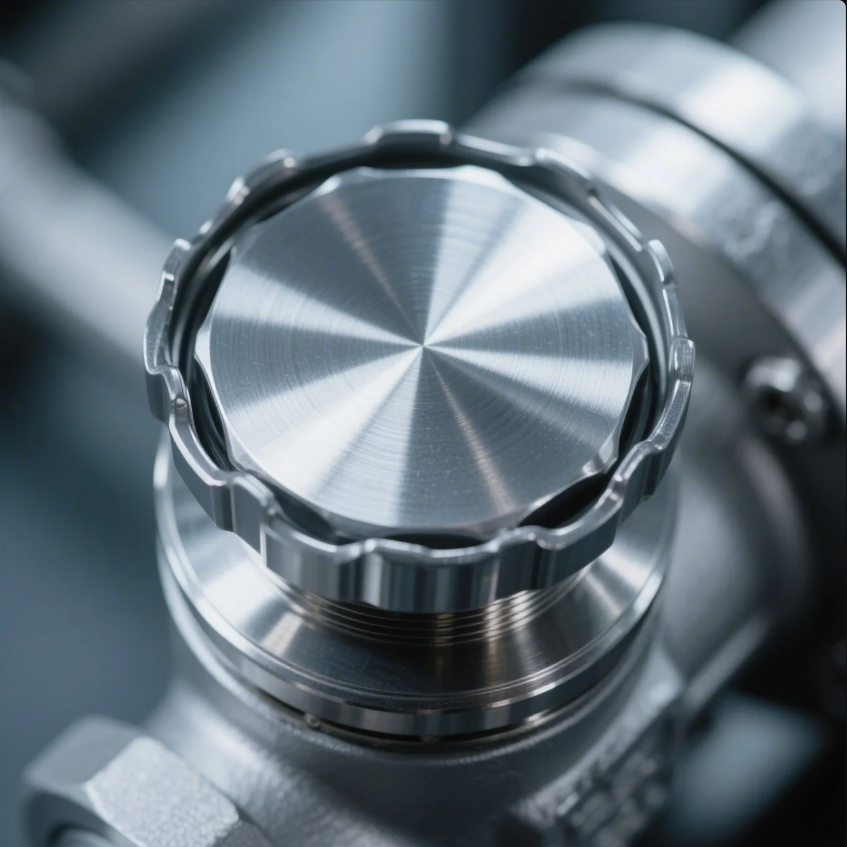

ISO9001 PG80 screw cap

Use our ISO9001 PG80 threaded cylinder cap, a metal cylinder component, to increase the efficiency of your industrial operations. With the precise thread design and excellent sealing performance, they are widely used in the field of high-pressure gas cylinders, and effectively guarantee the safety of gas storage and long-term stable operation.

Gas cylinder cap for valve protection

Improve the safety of your industrial equipment with our metal cylinder component, the cylinder cap designed for valve protection. With durable structure and precise fit, they are widely used in all kinds of gas cylinder packaging and transportation, effectively prevent valve damage, ensure the stability and safety of the use process.

Cylinder Regulator Protector helmet

Use one of our metal cylinder components, the cylinder regulator protector helmet, to improve your safety in industrial operations. With their robust protective structure and reliable impact resistance, they are widely used in various industrial gas cylinder systems, effectively protecting regulators from collision and damage, and ensuring the stable operation of gas delivery systems.

Customizable steel cylinder safety valve guard

Improve the safety of your industrial system with our customizable cylinder steel safety valve protector, a metal cylinder component. With strong steel structure and flexible custom ability, they are widely used in all kinds of high pressure cylinders, effectively protect the valve from impact and damage, ensure the safety and reliability of gas storage and transportation process.

Custom steel gas cylinder safety cap

Use our custom-made steel cylinder safety cap, a metal cylinder component, to enhance the protection of your industrial equipment. With excellent compressive strength and precise design, they are widely used in gas cylinder storage and transportation process, effectively protect the valve components, ensure the safety and reliability of operation.

Gas cylinder safety guards or steel handles

Use our metal cylinder components-high-strength cylinder safety device and steel handle, to enhance your industrial safety and convenience. With excellent structural design and durable materials, they are widely used in all kinds of gas cylinder handling and use scenarios, effectively preventing accidental damage, ensuring operator safety and improving operation efficiency.

Cage type protection device for compressed gas valve

Improve the safety of your cylinder system with our special cage protector for compressed gas valves. With strong structure and comprehensive protection coverage, they are widely used in high pressure gas storage and transportation, effectively prevent valve collision damage, ensure safe operation and long-term stable operation of equipment.

Custom cast steel gas cylinder shroud

Improve the safety of your industrial equipment with our custom steel cylinder shield, a metal cylinder component. They are widely used in all kinds of industrial cylinders due to their durable cast steel structure and precision customization ability. They effectively protect valves and key components and ensure safe and stable operation during handling and use.

Valve Protector for ABS cylinders

Use our metal cylinder components-ABS cylinder valve protection device to improve the safety of your industrial equipment. With excellent impact resistance and lightweight structure, they are widely used in all kinds of portable or industrial cylinders, effectively protecting valves from accidental impact and damage, and ensuring the safety and stability of transportation and operation processes.

Valve protectors for steel cylinders

Use our metal cylinder components-steel cylinder valve protectors to enhance your level of industrial safety. With strong structural strength and excellent protection performance, they are widely used in high pressure cylinder system, effectively resist external impact, prevent valve damage, ensure the stability and safety of the operation process.

General Hot Selling Products

Prime manufactures a wide range of gas cylinder assemblies for the compressed gas industry, the utility model comprises a shell, a neck ring, a compressed gas flange, a can sleeve ring, a can cover, a can handle, a compressed gas joint, a cylinder casing and a cylinder foot ring.

Compressed Gas Tank Shells

We offer compressed gas tank shells that can be customized to your specifications. Our tank shells are available in stainless steel, aluminum, and carbon. You have the option to choose your height, diameter, and wall thickness as well as your end shape.

Features:

High strength pressure bearing structure

Excellent sealing performance

Strong corrosion resistance

Compressed Gas Neck Rings

The cylinder neck ring mounts to a seamless high-pressure gas cylinder to provide a means of attachment for the cylinder valve protection device, such as a cap, valve guard, or other valve protection device.

Features:

Stability of high strength connection

Excellent sealing performance

Strong corrosion and wear resistance

Compressed Gas Flanges & Spuds

Compressed gas tank flanges are often used on cylinder tanks in the oil and gas industry. A flange is an external or internal ridge that is used for strength or for attachment to another object. The flanges help to make the compressed gas tank safer. We manufacture compressed gas tank flanges to your specifications.

Features:

Precise threaded connection, reliable seal

Design for withstanding high voltage

Both material strength and corrosion resistance

Compressed Gas Tank Collars

Our compressed gas tank jacket is similar to a tank cap and provides safety protection to propane, Liquefied petroleum gas and natural gas suppliers from the outside environment. This combination allows the user to easily operate the compressed air valve through the side opening and the top for filling and connection.

Features:

Protect the bottle valve from collision damage

High strength material, strong corrosion resistance

Adapt to a variety of bottle type, support custom structure

Compressed Gas Tank Lids

The cover of compressed gas tank is an indispensable safety protection device in the transportation and storage of gas cylinders. It is designed to protect the cylinder valve from collision, dust, moisture and foreign matter, ensure the safety of gas tank in all kinds of environment. We offer a wide range of cap sizes and constructions for industrial gases, Liquefied petroleum gas gases (LPG) , medical gases and more, supporting custom sizes and markings to meet the diverse needs of the global market.

Features:

Design of anti-collision protection

Standard threaded interface for easy installation

Customizable vent and latch construction

Compressed Gas Tank Handles

The handle of compressed gas tank is an important accessory designed for portability and safe operation. It is widely used in industrial gas, medical gas and outdoor gas cylinders. By optimizing the structure and material selection, the gas tank handle not only improves the handling efficiency, but also plays the role of cylinder valve protection to a certain extent. We can provide a variety of specifications, installation and color customization, to meet the needs of different cylinder models and use of the environment.

Features:

Easy to carry, easy to operate

High-strength material, reliable load-bearing

Diversified structure design, strong adaptability

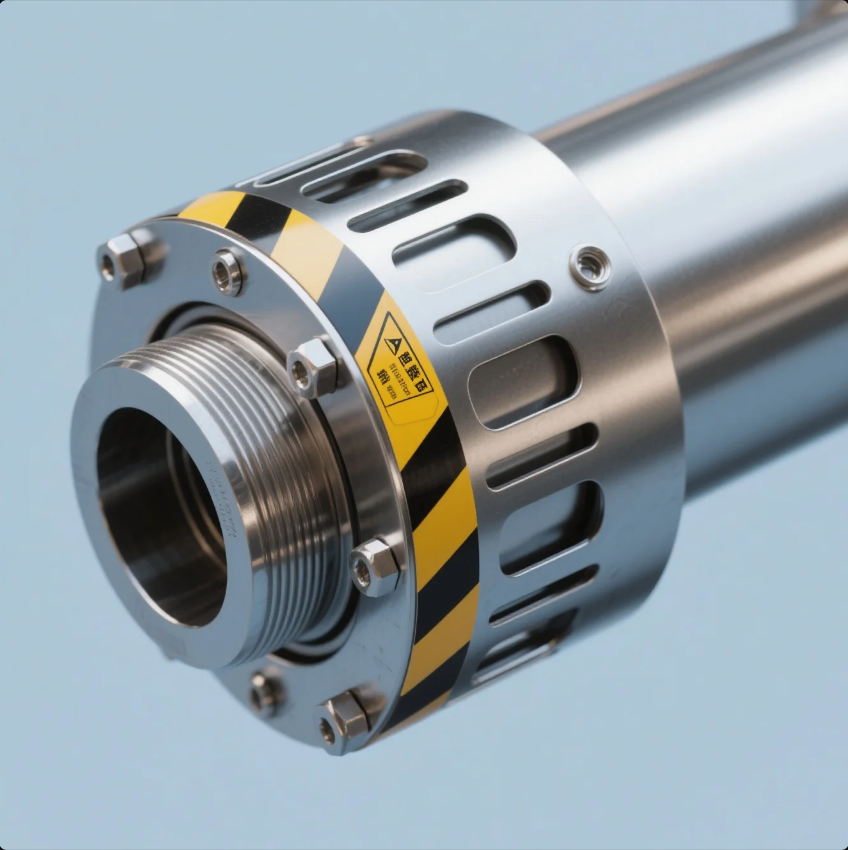

Compressed Gas Cylinder Sleeves

The cylinder liner of compressed gas is a key protection and reinforcement component used in high-pressure gas storage system. It is mainly used to wrap the cylinder body to improve its impact resistance, wear resistance and structural stability. Widely used in industrial gases, medical gases, special gases and other fields. We provide a variety of materials, structures and sizes of customized cylinder liners to meet the needs of safety protection under different pressure levels and working conditions.

Features:

Enhance the strength of the structure, improve service life

High quality material, strong corrosion resistance

Support for personalized customization, compatible with multi-standard bottle

Compressed Gas Tank Foot Rings

The foot ring of compressed gas tank is an important supporting part at the bottom of the cylinder, which is designed to enhance the stability of the cylinder body, prevent dumping and wear at the bottom, and play an effective protective role in the process of transportation and storage. We can provide a variety of specifications of metal anklets, adapt to different diameters and standards of cylinders, widely used in industrial gas, medical oxygen, liquefied gas and other fields. The products support customized sizes, constructions and finishes to meet the diverse needs of the global market.

Features:

Stable support, anti-dumping design

Durable, impact and corrosion resistant

Standard compatible, easy to install and replace

In Summary

Different types of cylinder components have their own unique structure and function, can be flexibly selected according to the pressure level of the cylinder system, working environment and installation mode. For high precision, high sealing parts, such as valve connector or neck ring, suitable for high strength, dimensional stability of precision machining parts; More emphasis on structural strength and corrosion resistance, and such as handle, ring and other auxiliary parts, is focused on the ease of operation and ergonomic design. By selecting the appropriate material, process and structure configuration, the overall performance of the cylinder can be significantly improved to meet the practical application requirements of industrial gases, medical treatment, transportation, energy and other fields.

Cost Analysis

The cost of customizing metal cylinder components is influenced by:

Material selection: different metal materials (such as carbon steel, stainless steel, aluminum alloy) unit price difference is larger, and the higher the material performance requirements, the higher the cost.

Structure and precision requirements: complex structures or high-precision (such as ± 0.01 mm) processing requires more man-hours and high-end equipment support, significantly increasing manufacturing costs.

Surface treatment process: such as spray, electroplating, phosphating and other processing not only increase the process, but also affect the environmental compliance and appearance requirements, directly affect the total cost.

Order quantity and delivery time: the larger the batch, the lower the unit cost; if urgent delivery or small batch trial production, the cost per piece will increase.

The Process Flow & Duration Estimation

To ensure that each metal cylinder component accurately matches customer requirements, we follow the following nine standard processes, covering every step from pre-technical confirmation to post-delivery testing:

Table of Contents

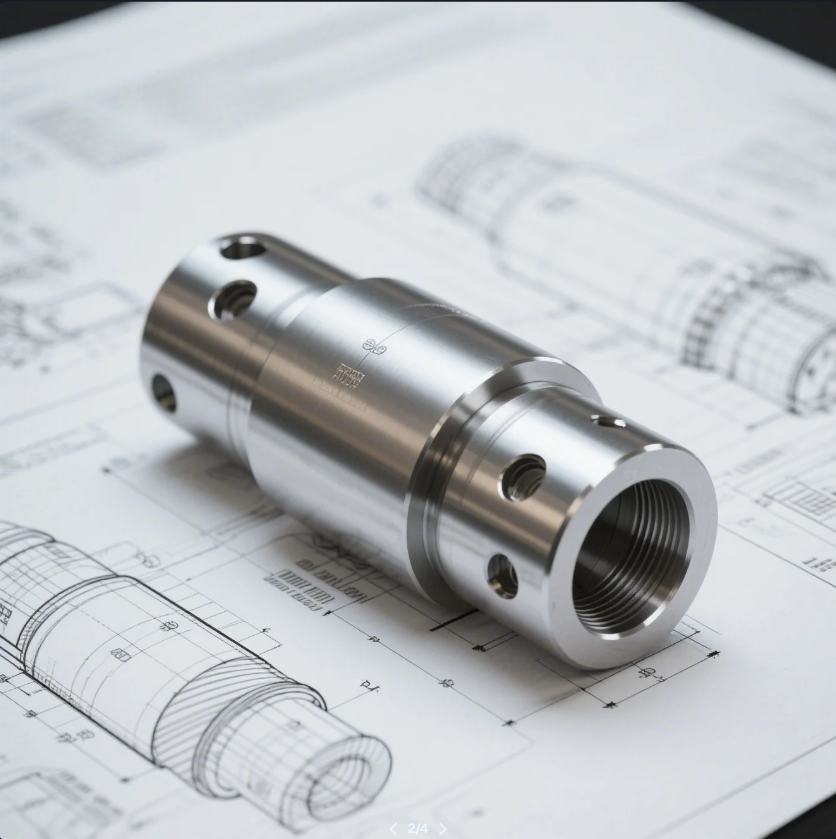

Step 1: Customer Requirements Validation and technical communication

At the beginning of the project, we communicated deeply with our clients, understand key information such as drawings (2D/3D CAD) or physical samples, service environment (such as pressure level, temperature, medium) , required materials (carbon steel, stainless steel, aluminum alloy, etc.) , we can also provide technical consulting services to assist customers to optimize the design, reduce costs and improve manufacturability.

Step 2: Process Evaluation and pricing

According to the drawings and technical requirements provided by customers, our engineering team will formulate the most suitable production process route -LRB-suchCNC CNC, welding, heat treatment, surface treatment, etc.) , calculate the cost according to material, man-hour and inspection requirement, provide complete quotation and expected delivery date.

Step 3: Engineering drawing confirmation and order

After quotation confirmation, we will generate engineering production drawings (including dimensional tolerance, assembly datum, material number, etc.) , and confirm technical details with customers again to avoid errors. After the customer signs the confirmation, the production schedule will be officially entered.

Step 4: Material Purchasing and production preparation

We purchase raw materials that meet international standards (such as ASTM, EN, GB brand) , and carry out warehousing inspection. Pre-process raw materials according to product structure, such as sawing, pre-drilling, CNC prefabrication, etc. , to prepare for the follow-up processing flow.

Step 5: Precision machining and Manufacturing Execution

According to the characteristics of parts design, into the core processing links, common processes include:

CNC turning and milling (CNC) : for machining neck, thread, flange and other key parts

Welding and splicing: commonly used in bottle body and neck ring, base, reinforcing rib and other combined structure

Tapping and boring: to ensure that the interface matching accuracy, to meet the Assembly and sealing performance

Heat treatment (e. g. quenching, annealing) : used to increase the strength of a material or to relieve stress

Step 6: Surface treatment and corrosion protection

We offer a wide range of surface treatments according to the needs of the industry and the environment:

Spraying or plastic spraying (to improve appearance and corrosion resistance)

Galvanization or hot-dip galvanization (to enhance weatherability)

Anodizing (mainly for aluminium alloy parts)

Phosphating, antirust oil coating (for transport or storage protection)

Step 7:Rigorous quality and performance testing

We perform process quality control to ensure that each component meets the standard requirements:

Measurement of dimensional accuracy (calipers, three coordinates)

Thread Gage inspection (inch, Metric, special thread)

Water/air pressure seal test (to ensure no leakage, no deformation)

Material Analysis and mechanical property test (provide third party test report according to customer’s requirement)

Weld inspection (MT/PT/UT)(for welded parts)

Step 8: Packaging and logistics

All cylinder parts will be custom packed according to customer export or shipping requirements:

Wooden cases, pallets, bubble wrap, shockproof foam

Affix product labels, warning signs, factory certificate

Optional support: sea, air, Express, global shipping

We will assist customers to prepare the necessary documents such as customs clearance documents, Packing List, invoice and Certificate of origin.

Step 9: Delivery and after-sales technical support

After delivery, we provide technical package (drawing, Test record, Operation Instruction) and after-sales support, including:

Installation instructions and Remote Assistance

Tracing of customized parts and matching of spare parts

Quick delivery service for follow-up batch orders

Want to know how to compress lead times?

In order to shorten the production and delivery cycle, we suggest that you tell us your needs in detail, and we will adjust the strategy flexibly according to your requirements to ensure your production and help you succeed!

The Common Pitfalls When Purchasing

In the procurement process of customized metal cylinder parts, due to many technical details such as material, structural accuracy, pressure requirements and surface treatment, if the control is not in place, easy to cause quality problems, delivery delays and even security risks. Here are some common purchasing pitfalls:

- False or shoddy material label: some suppliers to reduce costs, the use of non-standard or recycled materials masquerading as regular metal materials (such as low-grade carbon steel masquerading as alloy steel) .

- Surface treatment process jerry-built: surface treatment layer thin, poor adhesion, easy to rust or fall off; part of the export products not according to the requirements of spray or galvanized.

- Lack of industry certification and export compliance documents: no ISO system, TPED/Dot and other export qualifications, affecting product customs clearance or end customer acceptance.

A Brief Self-Nomination, Why Choose Prime?

At Prime, you just tell us what you need. We offer a variety of high-quality custom metal cylinder components to ensure your business gets the best performance and value.

Rich experience: we have more than 30 years of cylinder parts production experience, can provide a variety of industries with high-quality custom metal cylinder parts.

Professional team: Our Engineering team is familiar with the production process of cylinder parts, and can provide accurate design and production services.

Quality assurance: WE ARE ISO 9001 certified to ensure that each cylinder component meets the highest standards of quality.

Rapid Response: We are committed to providing rapid sample production and production cycle to ensure that your needs can be met in a timely manner.

Global Service: No Matter where you are, we can provide you with quality services to ensure the smooth progress of your business.

Get in touch

Easy Customization Of Metal Cylinder Parts

Share detailed information about your needs, including drawings, reference images, and any specific ideas or specifications you have in mind.

Based on your requirements and design, we’ll provide a custom solution and send you a detailed quote within 24 hours.

Once you approve the design and quote, we’ll begin mass production and take care of the shipping, ensuring timely delivery.

Get a Free Quote

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.