Die Casting vs. Investment Casting: A Complete Comparison for Industrial Buyers

Choosing the wrong casting method results in wasted budget and poor product performance.

Die casting and investment casting serve different industrial goals. One suits high-volume, precise applications. The other offers design flexibility and superior finishes. This guide compares them side by side.

If you're an engineer or procurement manager struggling to balance cost, quality, and delivery time, this article is your shortcut to informed decisions.

Mechanical Properties and Surface Finish Differences Explained

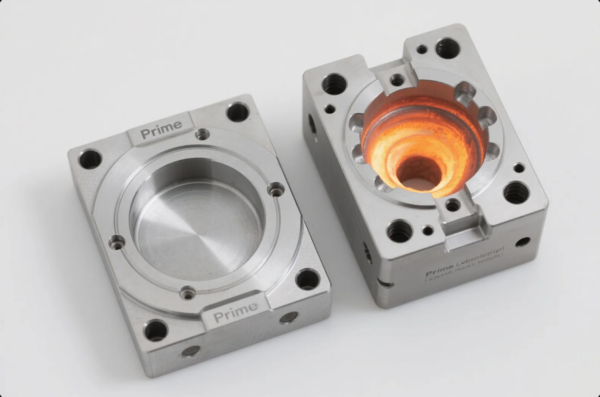

Die casting produces stronger, more rigid parts with tighter dimensional tolerances. Investment casting excels in surface finish and complex geometries.

In industries like automotive or defense, the difference between these properties matters. Die casting creates high-density parts through rapid solidification. This reduces micro-voids and enhances mechanical integrity. Investment casting, by contrast, provides nearly flawless surfaces due to its ceramic shell mold and slow cooling.

At Prime, we see clients use die casting for components like electronic housings that require strict enclosure fit. On the other hand, medical tool companies choose investment casting for clamps and surgical frames where precision is key.

| Property | Die Casting | Investment Casting |

|---|---|---|

| Tensile Strength | High (due to fast solidification) | Moderate to High |

| Surface Finish | 3.2–6.3 Ra | < 3.2 Ra (near net shape) |

| Wall Thickness | Thinner walls achievable | Slightly thicker walls |

| Internal Porosity | Controlled via vacuum/chill dies | Lower porosity with shell design |

| Machinability | May need finishing | Often no further machining |

Sources like AZoM’s mechanical guide and Die Casting Design Center explain how to optimize tolerance and durability depending on use case.

Cost and Volume Suitability: Which Casting Is More Efficient?

Die casting is more cost-effective at high volumes due to reusable metal dies. Investment casting is better for medium volumes or complex one-offs.

Tooling is the largest initial barrier to die casting. Steel molds are durable but expensive. However, when amortized over 100,000+ units, per-part cost drops dramatically. Investment casting tools use wax and ceramic, which are cheaper and quicker to prepare but degrade faster.

At Prime, we typically recommend:

- Die casting for customers ordering more than 10,000 units/year.

- Investment casting for prototyping, small batches, or parts with high contour detail.

| Factor | Die Casting | Investment Casting |

|---|---|---|

| Tooling Cost | High | Medium |

| Unit Cost (Low Qty) | High | Moderate |

| Unit Cost (High Qty) | Low | Moderate |

| Lead Time (Initial) | 4–6 weeks | 3–5 weeks |

| Best For | 10,000+ units | 100–5,000 units |

Read more on ThomasNet's comparison or Dynacast's cost calculator.

Which Materials Work Best for Die vs. Investment Casting?

Die casting is limited to non-ferrous metals like aluminum, zinc, and magnesium. Investment casting handles steel, stainless steel, nickel, and exotic alloys.

Material selection impacts strength, corrosion resistance, and cost. A buyer sourcing components for marine use needs stainless steel or bronze. That rules out die casting. Investment casting is often the only viable option.

Prime offers advice based on operating temperature, environmental exposure, and regulatory standards. We’ve worked with clients in aerospace who needed cobalt-chrome alloy for turbine blades and others who used duplex stainless steel for chemical pumps.

| Alloy Type | Die Casting | Investment Casting |

|---|---|---|

| Aluminum Alloys | Yes | Yes |

| Zinc Alloys | Yes | Rare |

| Magnesium | Yes | Rare |

| Carbon Steel | No | Yes |

| Stainless Steel | No | Yes |

| Nickel Alloys | No | Yes |

| Cobalt/Exotics | No | Yes |

Explore more at Matmatch Material Index or TotalMateria Database.

Real-World Applications in Automotive, Aerospace, and Machinery

Die casting dominates automotive and consumer goods. Investment casting is vital in aerospace, turbines, and medical tooling.

At Prime, we’ve delivered:

- Automotive: Die cast ECU casings and aluminum transmission covers

- Aerospace: Investment cast jet turbine stators, landing gear brackets

- Medical: Orthopedic toolsets, stainless bone plates

- Energy: Valve housings for offshore rigs in Inconel

Die casting is favored where volume and shape simplicity align. Investment casting is used where internal complexity, thin walls, and alloy diversity matter.

Read industry examples at MetalTek Applications and Dynacast Case Studies.

FAQs on Die vs. Investment Casting

Which is better for small batches?

Investment casting has lower tooling cost for low volumes.

Which process is faster for production?

Die casting wins in long runs; investment casting is faster to start.

Can both achieve tight tolerances?

Yes. Die casting holds ±0.1 mm; investment casting ±0.25 mm.

Which one is cheaper per part?

Die casting is cheaper per part when quantity exceeds 10,000.

Can Prime help with both?

Yes. We support both technologies, including CNC finishing.

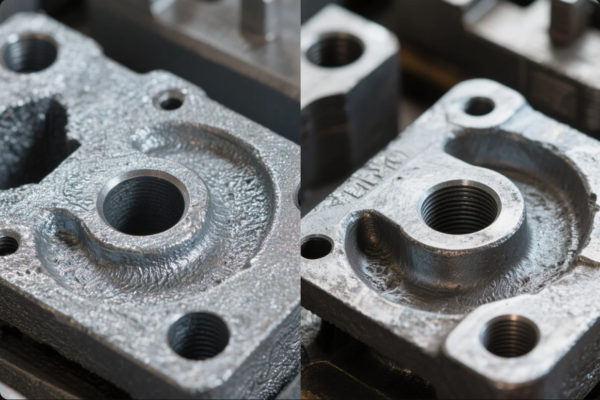

Which casting process has fewer defects?

Properly managed, both achieve defect rates under 1%. Investment casting may show better surface quality out-of-the-box.

What post-processing is needed?

Die castings often need machining or coating. Investment castings may require only polishing or slight trimming.

Conclusion and Contact

Choosing between die and investment casting depends on your budget, part complexity, volume, and alloy.

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com

Get a free quote and technical consultation today from our casting specialists at Prime.

We help global buyers get quality-certified parts with short lead times and full support from prototyping to mass production.