What is meant by galvanization?

Galvanization coats steel with zinc. It prevents rust instantly. Many clients face metal corrosion regularly. As a result, parts degrade faster. Galvanizing extends metal life and lowers costs.

Galvanization applies a zinc layer to steel to block corrosion. It enhances durability in harsh and outdoor environments.

I have personal experience with galvanized parts. Once, I saw a non-galvanized component fail after months. Later, a similar part with zinc lasted years. That prompted me to adopt galvanization widely.

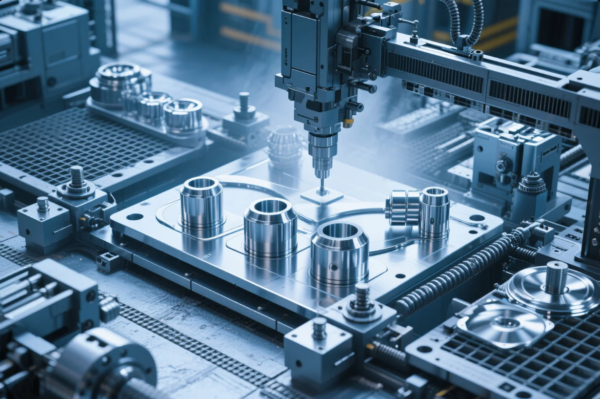

Galvanization technology and types

Galvanizing takes several forms. Each has pros and cons:

- Hot‑dip galvanizing — steel is dipped into molten zinc and coated according to ASTM A123 standard.

- Electro‑galvanizing — zinc is applied via electric current as per ISO 2081 standard.

- Zinc spraying — molten zinc is thermally sprayed, a method explained by ASM International.

Hot-dip provides deep penetration and rugged finish. Electro-galvanizing offers uniform coating. Thermal spray targets hard-to-coat shapes.

These techniques are selected based on cost, precision, and product application.

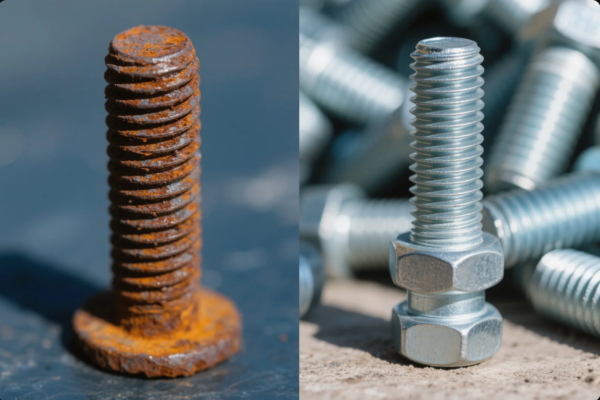

What is the difference between rusting and galvanization?

Rust damages metal. Galvanization protects it. They work in opposite ways.

Rusting occurs when iron reacts with oxygen and moisture, as shown in the Corrosion Science Journal. Galvanization blocks this reaction by forming a zinc barrier and sacrificing itself when exposed to corrosion sources, as detailed on Galvanize It!.

| Factor | Rusting Effect | Galvanization Effect |

|---|---|---|

| Appearance | Brown, flaky | Shiny, durable |

| Maintenance | High | Low |

| Lifecycle | 5–10 years | 20–50+ years |

What does it mean to galvanize people?

“Galvanize” also means to energize or inspire people into action. That spark often comes from emotional urgency or team goals.

To galvanize people means to inspire immediate action, often in a powerful or urgent context.

I remember a delayed shipment that motivated our team. We regrouped, adapted our process, and hit the deadline. That’s the spirit of being galvanized.

It parallels business dynamics as explained in this Harvard Business Review article.

What does it feel like to be galvanized?

You feel galvanized when something inspires you to act fast and decisively.

That feeling triggers swift decisions or renewed commitment to a goal.

In business, strong results or a shared mission can galvanize teams to exceed expectations. I’ve seen it happen during tight project deadlines, where a clear goal led to extraordinary teamwork.

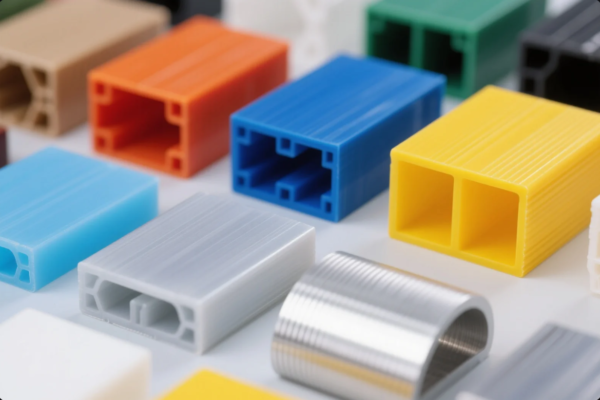

Industrial applications of galvanization

Galvanized parts are essential in:

- Construction — beams, bolts, scaffolding

- Automotive — frames, chassis brackets

- Electronics — cases, ground plates

- Marine — dock fittings, chains

- Agriculture — fencing, irrigation parts

Explore more real-world usage examples in this project gallery.

These industries prefer galvanized components for long-lasting protection, reduced maintenance, and total cost savings.

How to choose quality galvanized parts?

When evaluating galvanized parts, check:

- Coating thickness — meet ASTM A123 or ISO 1461

- Zinc adhesion — no flaking under stress

- Surface uniformity — especially on corners and edges

- Salt spray resistance — proven in Nord-Lock's corrosion tests

| Quality Criteria | Minimum Standard |

|---|---|

| Thickness | 85μm (standard), up to 200μm |

| Surface finish | Smooth, bubble-free |

| Test compliance | ISO, ASTM |

Case Study: HVAC Bracket Failures Solved

A U.S. HVAC manufacturer struggled with rusty support brackets. After switching to Prime’s galvanized CNC parts, part failure dropped from 30% to under 2%, and yearly maintenance costs decreased from \$18,000 to \$1,400.

More on similar successes in this galvanization success story.

Galvanized vs Painted vs Stainless Steel

| Feature | Galvanized | Painted Steel | Stainless Steel |

|---|---|---|---|

| Cost | Low | Medium | High |

| Maintenance | Low | High | Low |

| Lifespan | 20–50 years | 3–7 years | 50+ years |

Compare more from Metal Supermarkets, Zinga Blog, and Outokumpu Stainless Guide.

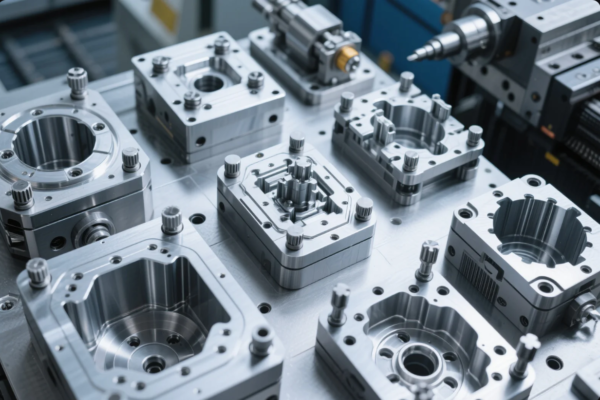

Why Choose Prime?

We are a manufacturer with:

- 30+ years experience in metal part production

- ISO 9001 certification (ISO standard)

- 10 production lines for stamping, CNC, casting, welding

- Fast delivery — 7 to 14 days for most orders

- Custom logos, packaging & inspections — visit our company profile

We serve clients in the USA, Europe, Middle East, and Australia with certified quality and responsive service.

FAQs

Can you galvanize aluminum?

No. Zinc does not adhere to aluminum. See explanation

Is it eco-friendly?

Yes. Zinc is recyclable and sustainable. More on sustainability

Can galvanized parts be welded?

Yes, but requires local ventilation. Welding safety guide

Do you provide inspection certificates?

Yes. Including coating thickness, material certs, salt spray test, and full QC.

Do you accept urgent orders?

Yes. Express production available for approved drawings or repeat clients.

Contact Prime

Galvanization builds confidence, reduces cost, and ensures long-term performance. Prime supports your supply chain with proven quality and fast response.

📩 Reach out now:

🌐 https://primecustomparts.com

📧 [email protected]

We respond within 12 hours. Get your free quote, drawings review, and expert support today!