The Ultimate Guide to Custom Metal Cylinder Components: Manufacturing, Applications, and Quality Control?

Manufacturers often face headaches with inconsistent quality, late deliveries, and poor communication when sourcing custom metal cylinder components.

This guide breaks down cylinder types, materials, quality standards, and common defects. Get expert insights and actionable tips. Optimize sourcing for stable quality, fast delivery, and clear communication.

Buyers everywhere deal with delays, unclear specs, and quality issues when ordering cylinder parts. Want to solve these challenges? Read on to learn proven solutions and discover Prime’s expertise as an ISO-certified custom cylinder parts supplier.

Table of Contents

- What Are the Main Types of Metal Cylinder Components Used in Industrial Applications?

- How to Select the Right Material and Process for Cylinder Components?

- Key Quality Standards and Certifications for Metal Cylinder Parts

- Common Defects in Cylinder Components and How to Avoid Them in Production?

- Frequently Asked Questions

- Contact Prime

What Are the Main Types of Metal Cylinder Components Used in Industrial Applications?

Many buyers feel lost with so many cylinder part options. The wrong choice can mean machine failure or lost revenue.

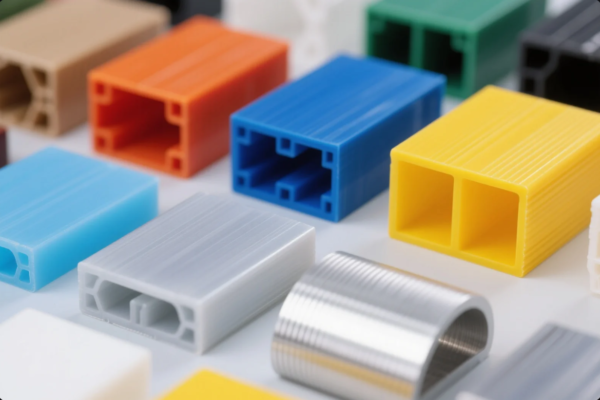

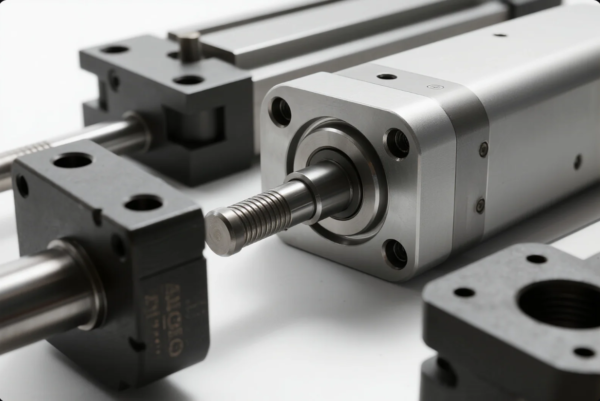

Main industrial cylinder components include hydraulic cylinders, pneumatic cylinders, precision tubes, end caps, rods, pistons, seals, and mounting brackets. Each part meets unique technical needs and strict performance standards. Choosing wisely helps ensure safety and long-term reliability.

Hydraulic and pneumatic cylinders form the backbone of heavy machinery in construction, manufacturing, and process industries. Hydraulic cylinders, for example, power excavators and heavy presses across the globe, while pneumatic cylinders are essential in automation and packaging lines. Precision cylinder tubes must offer smooth internal surfaces and high strength, as described in Hydraulic Cylinder World’s technical resources. Piston rods, often manufactured from chrome-plated steel, are engineered for wear and corrosion resistance. End caps, flanges, and seals guarantee safe, leak-proof assembly, making them vital for all types of OEM machinery.

Many sectors—like mining, automotive, energy, and construction—need components designed for high-pressure and high-cycle environments. It’s always a good practice to check Parker Hannifin’s cylinder selection guide or Matmatch’s material comparison tool to verify specifications and ensure compatibility.

Main Types of Cylinder Components

| Component Type | Industrial Use | Material | Key Feature |

|---|---|---|---|

| Hydraulic Cylinder | Excavators, Presses | Steel, Alloy | High pressure resistant |

| Pneumatic Cylinder | Automation, Robotics | Aluminum, Steel | Lightweight, precise |

| Cylinder Tubes | All Industries | Steel, Stainless | Smooth ID, strong OD |

| Piston Rods | Machinery, Valves | Chrome Steel | Corrosion resistant |

| End Caps & Flanges | Custom Assemblies | Steel, Cast Iron | Easy assembly |

| Mounting Brackets | System Integration | Steel | Secure installation |

| Seals & Gaskets | Leak Prevention | NBR, Viton | High temp/pressure |

To stay informed on recent innovations, I recommend regularly checking The Fabricator for updates on manufacturing methods and Foundry Planet for casting insights.

How to Select the Right Material and Process for Cylinder Components?

Material and process selection can make or break a project. The wrong material or method results in early failure, corrosion, or high costs. I see many buyers confused by technical data or price differences.

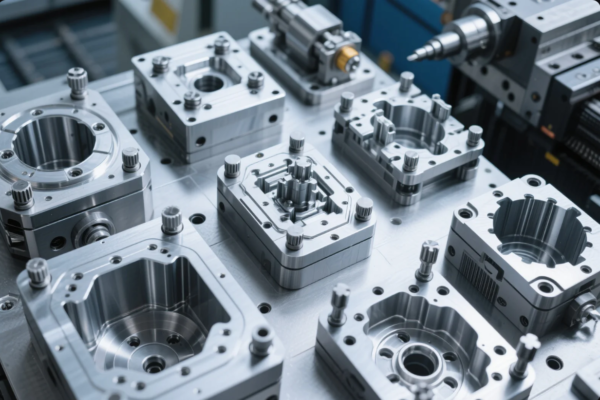

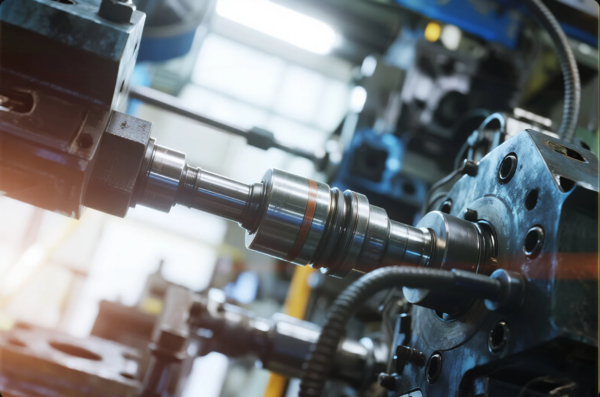

Cylinder materials include carbon steel, alloy steel, stainless steel, and aluminum. Production processes cover stamping, CNC machining, casting, and welding. Match material and process to your project’s demands for optimal cost and performance.

In my experience, heavy-load cylinders for mining or presses perform best with alloy steel and deep chrome plating, while lightweight and corrosion-prone environments, such as food or pharmaceutical plants, require stainless steel or aluminum with a polished surface. High-volume runs favor stamping and automated welding for cost savings and speed.

For food-grade or medical cylinder parts, always review Granta Design’s engineering materials database and check compliance with RoHS standards to avoid toxic elements. Before finalizing, collaborate with suppliers who use AutoCAD or SolidWorks for drawing review, ensuring every custom requirement is clear.

Key Factors When Choosing Material and Process

| Application | Material | Process | Reason |

|---|---|---|---|

| Heavy Duty | Alloy Steel | CNC Machining | High strength, tight tolerance |

| Corrosive | Stainless Steel | Casting, Machining | Rust proof, long service life |

| High Volume | Carbon Steel | Stamping, Welding | Economical, repeatable |

| Custom/Prototype | Aluminum | CNC Machining | Fast turnaround, lightweight |

| Food Grade | 304/316 SS | Polished Machining | Sanitary, easy clean |

Industry platforms like ThomasNet and EngineeringClicks offer practical insights into the selection process. If you want robust components that deliver under real-world conditions, look for factories with proven case studies on Hydraulics & Pneumatics and Bosch Rexroth.

Key Quality Standards and Certifications for Metal Cylinder Parts

Quality standards and certification are critical for import compliance and product reliability. Many buyers overlook these, risking customs delays or rejections.

The most important certifications are ISO 9001, ISO/TS 16949 (for automotive), and sometimes CE or RoHS. These confirm a supplier’s process control, safety, and compliance with international standards.

Prime’s factory holds ISO 9001 certification and can supply ISO/TS 16949 documentation for automotive projects. European Union buyers often need CE and RoHS compliance as proof of safety and environmental responsibility. You should always verify a supplier’s claims using sources like IAF CertSearch and SGS’s certification directory.

Before shipment, ask for test certificates and material traceability from your supplier. Detailed inspection data and process audits, such as those offered by TÜV Rheinland and Bureau Veritas, help prevent disputes and ensure compliance in your country.

Main Quality Standards

| Standard | What It Covers | Why It Matters | Official Link |

|---|---|---|---|

| ISO 9001 | Quality Management System | Stable quality | ISO 9001 |

| ISO/TS 16949 | Automotive Industry | Full traceability | IATF Global |

| CE Mark | EU Product Safety | Legal market entry | Europa CE |

| RoHS | Hazardous Substances | Environmental safety | RoHS Guide |

You can find further best practices at DNV’s certification resources and get regulatory updates from Export.gov.

Common Defects in Cylinder Components and How to Avoid Them in Production?

Defects can halt your production or damage your brand’s reputation. Many companies lose clients because of hidden flaws in delivered cylinder components.

Frequent defects include welding cracks, incorrect dimensions, bad surface finish, porosity, and packaging damage. Prevention depends on ISO-level process control, in-process inspection, and skilled workers.

I always recommend working with suppliers who perform in-process and final inspections, using Mitutoyo measurement tools and ZEISS CMMs. Defect prevention begins with proper welding technique, quality raw materials, and strict packing according to ISTA standards.

Prime’s process includes digital traceability and photo confirmation for every batch. If you want to reduce risks, review case studies at The Welding Institute (TWI) and see best practices for corrosion protection and export packaging.

Common Defects and Prevention

| Defect | Root Cause | Prevention Steps | More Info |

|---|---|---|---|

| Welding Cracks | Bad prep/welding process | Skilled staff, preheat metal | Welding Defects |

| Size Deviation | Outdated machines/poor checks | Use CNC, inspect every batch | CNC Quality Tips |

| Surface Flaws | Worn tools/dirty lines | Tool upkeep, clean benches | Metal Surface Finish |

| Rust/Corrosion | Poor coating or packaging | Chrome/stainless, export packing | Corrosion Protection |

| Porosity (Casting) | Bad melt or venting | Vacuum casting, X-ray tests | Casting Porosity |

| Packaging Damage | Weak cartons/poor stacking | Multi-layer crates, shrink wrap | Export Packing Guide |

Prime’s system includes full QC documentation, third-party audits from SGS, and real-time updates for clients—these methods significantly reduce defect risk.

Frequently Asked Questions

Q1: What is the lead time for custom cylinder parts?

Lead times vary by complexity and order size. Prime typically ships samples in 7-15 days, mass production in 20-30 days, in line with Alibaba’s best practices.

Q2: What packaging do you offer to avoid damage?

Prime uses multi-layer cartons, foam inserts, and custom wooden crates. Our approach aligns with global ISTA standards and the Export.gov packaging guide.

Q3: How do you ensure consistent part quality?

We use 100% visual inspection, digital measurement, and surface finish analysis, based on ISO Inspection Procedures.

Q4: What payment terms are available?

We accept T/T, L/C, and PayPal for flexible transactions, following guidance from Wise Global Payments.

Q5: Can I request a custom logo or marking?

Yes, we offer laser engraving and part numbers, using reliable industrial marking technology.

Q6: How do you handle urgent or rush orders?

Prime leverages 10 production lines and partners with DHL Express and FedEx for fast global logistics.

Q7: Can you supply test certificates and material traceability?

We provide mill certificates and RoHS/CE reports, ensuring full traceability.

Q8: What industries do you supply?

We serve automotive, mining, construction, energy, food, and OEM machinery clients, much like those featured on Hydraulics & Pneumatics.

Q9: How do I submit a drawing or request a quote?

Send your PDF, DWG, or STEP files to [email protected]. For RFQ tips, visit ThomasNet.

Q10: Where can I see Prime’s full capabilities and success stories?

Visit our official website and review our projects.

Contact Prime

For a free consultation, fast quote, or custom solution, reach out to Prime today. Our team delivers reliable, ISO-certified cylinder parts with rapid lead times and steady quality. Trust Prime for hassle-free sourcing and one-stop service.

Website: https://primecustomparts.com/

Email: [email protected]

Conclusion

Custom cylinder parts need careful design, the right materials, strict quality control, and an ISO-certified supplier.

Contact Prime now for expert consultation and fast, reliable service.ND