How to Choose a Reliable Metal Cylinder Components Manufacturer: Key Criteria for B2B Buyers?

Buyers often risk late deliveries, unstable quality, or poor service by choosing the wrong metal cylinder components supplier.

This guide helps B2B buyers screen Chinese manufacturers for quality, customization, delivery, and real-world success. Get practical questions and proven criteria for confident sourcing.

Sourcing cylinder parts is a high-stakes decision. If you want to reduce risk, ensure compliance, and get responsive support, keep reading to see what separates top suppliers from the rest.

Table of Contents

- What Questions Should You Ask When Sourcing Metal Cylinder Parts from China?

- Customization Options: Logo, Surface Finish, and Special Dimensions for Cylinder Components

- The Importance of Fast Delivery and Supply Chain Management in Cylinder Components Supply

- Case Study: Successful Projects Using Custom Cylinder Components in Different Industries

- How to Audit and Visit Your Metal Cylinder Components Supplier?

- What to Look for in Supplier Communication and After-Sales Support?

- How to Evaluate Cylinder Component Samples and Test Batches?

- Frequently Asked Questions

- Contact Prime

What Questions Should You Ask When Sourcing Metal Cylinder Parts from China?

Sourcing from China brings price advantages but also risks like inconsistent quality, fake certificates, or delayed shipments. I often see buyers rush orders without enough due diligence.

Key questions include: What international certifications do you hold? Can you show real inspection reports? How do you handle urgent shipments? Who is my day-to-day contact? What’s your after-sales process?

To ensure you get genuine ISO 9001 or ISO/TS 16949 suppliers, always request their original certificates and check them on IAF CertSearch or third-party bodies like SGS and TÜV Rheinland. For the best inspection technology, suppliers should use Mitutoyo or ZEISS instruments. Don’t hesitate to request video calls or a virtual factory tour. Top suppliers will share live production status or walk you through QC protocols. Always confirm incoterms and logistics options—such as FedEx, DHL, and Maersk—plus export records to North America, Europe, and Australia.

Ask about past projects in your field and verify their customer feedback via Trustpilot or Alibaba’s ratings. Explore in-depth guides at ThomasNet and Made-in-China.com. Also, it’s wise to check supplier compliance history through Bureau Veritas or Dun & Bradstreet.

Smart buyers should also check which ERP system the factory uses, and whether they can support traceable production and real-time order tracking. If your company works with specialized packaging, ask about their experience with ISTA-certified packaging and export moisture control standards.

Key Supplier Questions

- Do you provide ISO or CE/RoHS certification?

- Can I visit your factory or see a virtual tour?

- Who manages my project and communications?

- How do you guarantee dimensional tolerances?

- What’s your on-time delivery rate?

- Can you provide references or past customer feedback?

- How do you pack parts for long-distance shipment?

- Will you handle urgent orders with dedicated lines?

- What payment terms and incoterms do you support?

- Can you provide inspection reports and batch traceability?

- Are you willing to sign NDAs and non-circumvention agreements for custom parts?

Customization Options: Logo, Surface Finish, and Special Dimensions for Cylinder Components

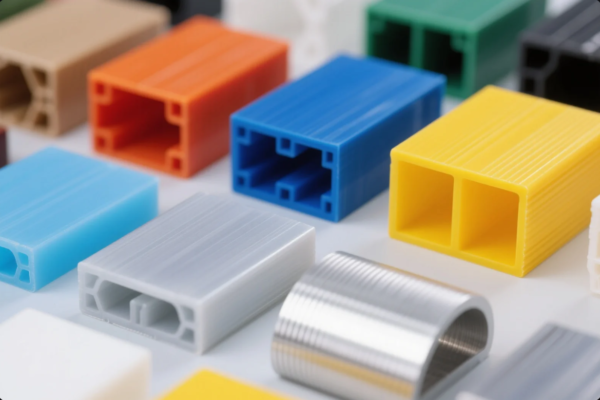

Standard parts rarely fit every project. Most clients ask for special sizing, branded logos, or unique coatings for performance and appearance.

Prime offers full customization: precision CNC machining for special bore or rod sizes, laser-engraved logos, various surface treatments like nickel, chrome, zinc plating, anodizing, and powder coating. We meet unique project specs quickly and efficiently.

Customization requests often include adding a company logo for traceability, special color coding for different markets, or adjusting thread types for unique installation needs. Advanced factories use SolidWorks and AutoCAD for precise DFM review. You should also check if the supplier can meet surface finish requirements, like Ra 0.8-1.6 for moving parts, or provide protective anodizing or powder coatings for outdoor use.

When working in harsh environments, ask about their salt-spray test data and their experience with corrosion-resistant coatings. Prime’s team offers special packaging and private label branding, meeting the highest export packaging standards.

Customization Checklist

- Custom bore and rod sizes (CNC/machining)

- Special logo and part number engraving (laser/stamping)

- Chrome, nickel, zinc plating, powder coat, anodize

- Unique mounting brackets, ports, or end cap shapes

- Custom threads (UNC, UNF, metric, BSP, NPT)

- Packaging: logo cartons, foam inserts, wooden crates

- Prototyping, small batch, and large-volume support

- Test reports for surface and salt-spray

For detailed examples of customization, review Xometry’s custom part projects and Parker Hannifin’s case studies.

The Importance of Fast Delivery and Supply Chain Management in Cylinder Components Supply

Many projects fail because of late parts. In my career, I’ve seen missed deadlines cost clients huge contracts and disrupt entire supply chains.

Fast delivery depends on a manufacturer’s in-house production capacity, supply chain transparency, and logistics partners. Prime operates 10 dedicated production lines, maintains buffer stock of core materials, and works with DHL, FedEx, and Maersk for global coverage.

A modern supplier should be able to show you real production dashboards or Kanban scheduling systems for urgent jobs. Look for flexible manufacturing lines and supplier networks that keep raw steel, fasteners, and packaging in reserve. Ask for written backup plans for supply chain disruptions and proof of relationships with multiple shippers, air freight providers, and customs brokers.

Suppliers who deliver globally should be familiar with RoHS/CE documentation, dangerous goods labeling, and country-of-origin certificates. In every project, I ask for real-time order status, advance shipment notifications, and digital copies of export documents before shipping.

On-Time Delivery Essentials

- 10+ in-house production lines with backup equipment

- Flexible scheduling for urgent orders and forecasted spikes

- Real-time order tracking, batch ID, and traceability

- Full customs and export document support

- Partnerships with global carriers and freight forwarders

- Redundant supply chain for raw material assurance

- Export packing per ISTA and Export.gov

Review SupplyChainDive, Logistics Management, and SupplyChainBrain for global best practices.

Case Study: Successful Projects Using Custom Cylinder Components in Different Industries

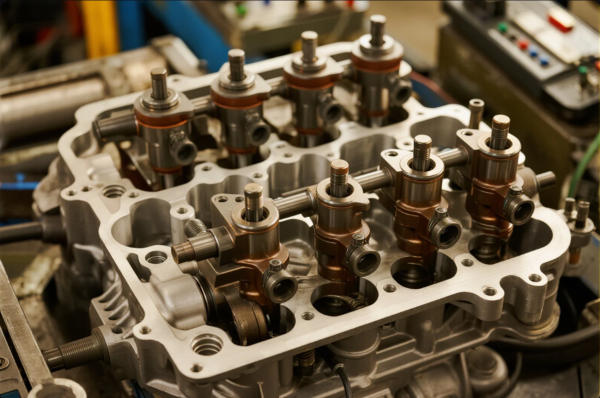

The real test of any manufacturer is proven results. I’ve worked on dozens of projects that needed advanced customization and strict deadlines.

One automotive client needed custom hydraulic cylinders with a complex mounting pattern and strict dimensional tolerance for a new EV assembly line. Prime engineered the components, provided 3D prototypes, and completed the full order in 24 days—saving the client from a \$200,000 penalty.

Another success came with an Australian mining equipment supplier who requested reinforced chrome-plated rods with laser-etched IDs. We supported their ISO/TS 16949 and RoHS compliance, delivered ocean shipments with Maersk, and provided ISTA-certified packaging. Prime’s batch inspection data and digital shipping labels streamlined their inventory process.

In the food processing industry, Prime’s stainless cylinder tubes with FDA-grade seals improved uptime for a European client’s automated packaging line. Our packaging with moisture-proof crates and digital tracking helped them reduce product returns and import headaches.

Prime has shipped to major OEMs in the US, Germany, Australia, and the Middle East. Our cylinders now support wind turbines, energy storage, and pharma automation.

Success Factors in B2B Projects

- Rapid DFM support and technical drawing review with SolidWorks

- Batch traceability and compliance documentation from SGS

- Real shipment photos, digital export labels, and packing lists

- Multilingual communication and technical support for global clients

- References and testimonials available from past projects

How to Audit and Visit Your Metal Cylinder Components Supplier?

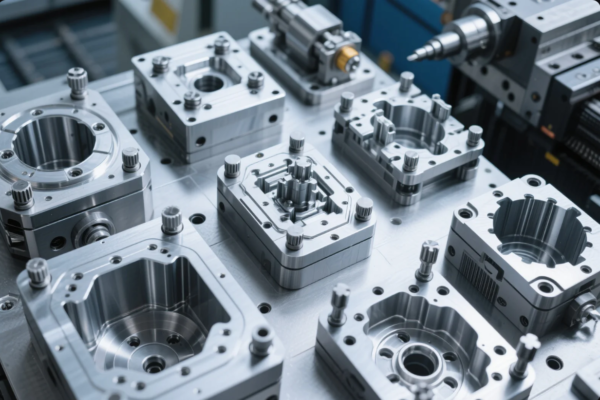

Factory audits remain one of the best ways to guarantee a supplier’s true capability. When possible, visit in person or hire a third-party auditor from SGS, Bureau Veritas, or TÜV Rheinland.

During the audit, check for:

- Separate production lines for CNC, welding, and stamping

- Dedicated QC labs with Mitutoyo and ZEISS measurement tools

- Marked material storage with batch traceability

- On-site ERP or MES systems for scheduling and inventory

- Staff certifications for welders, machinists, and inspectors

- Packing areas meeting ISTA export standards

Ask to see live production, random QC checks, and recent client shipment records. Many suppliers now offer virtual tours and remote video audits to support clients during travel restrictions.

What to Look for in Supplier Communication and After-Sales Support?

Communication is often underestimated, but it directly affects every order. Strong suppliers assign English-speaking account managers or bilingual engineers for real-time support on WeChat, WhatsApp, or email.

Check if the supplier can provide:

- 24-hour response to technical questions

- Fast engineering changes or drawing revisions

- Digital reports with QC photos and test data

- Support for customs clearance or logistics emergencies

- Documented after-sales process: root cause, corrective action, and replacement timelines

Prime builds relationships through proactive updates and open channels. We provide root cause analysis and send free replacements for confirmed quality issues, always following ISO 9001 quality procedures.

How to Evaluate Cylinder Component Samples and Test Batches?

Before any mass order, always request samples or test batches. Insist on receiving:

- Samples with full dimensions, finish, and logo/ID

- Digital QC reports with actual measurement data

- Photos or video of real packaging and shipment preparation

- Salt spray and material hardness test reports for critical parts

- Written confirmation of batch number and traceability

Experienced suppliers use advanced CMM equipment and document results digitally. If you need a specific process, such as chrome plating or anodizing, ask for a cross-section analysis and adhesion test report. For export, request ISTA-compliant packaging and see if the supplier can label for Amazon or major warehouse networks.

Frequently Asked Questions

Q1: How do I check if a Chinese supplier’s ISO certificate is real?

Use IAF CertSearch or request direct verification from SGS or TÜV Rheinland.

Q2: Can you provide samples with my custom logo before production?

Yes, Prime offers samples with logos, supporting AutoCAD or SolidWorks.

Q3: What is the average delivery time?

Standard orders ship in 20-30 days. Rush samples go out in 7 days via DHL Express.

Q4: Can you help with customs clearance?

Yes, our team prepares export documents and arranges global freight.

Q5: What packaging do you use for sea and air freight?

We use ISTA-certified packaging, foam, and wooden crates for export safety.

Q6: How do you handle after-sales issues or complaints?

Prime offers live support, root cause analysis, and free replacement for confirmed issues.

Q7: Can you produce according to international drawings and standards?

Yes, we use ISO tolerances, DWG, STEP, and PDF formats.

Q8: Where can I see Prime’s capabilities?

Visit https://primecustomparts.com/ for our project gallery, case studies, and product range.

For more answers, check Made-in-China’s FAQ or Alibaba’s buyer help center.

Contact Prime

For a free consultation, rapid quote, or a custom sourcing plan, contact Prime today. We guarantee ISO-certified quality, full customization, and fast, stable delivery for all your cylinder component needs.

Website: https://primecustomparts.com/

Email: [email protected]

Conclusion

A reliable cylinder component supplier answers your questions, supports real customization, delivers on time, and proves value with global case studies.

Reach out to Prime now—get expert advice, verified quality, and a stress-free sourcing experience.