Cylinder Neck Ring Procurement Guide: What Industrial Buyers Must Know?

Table of Contents

- Key Material, Corrosion Resistance, and Pressure Endurance Criteria

- Lead Time and Delivery: Small Batch Trials vs Bulk Orders

- The Importance of ISO 9001, TPED, and DOT Certifications

- RFQ Template: How to Efficiently Request Quotes and Evaluate Suppliers

- Supplier Audit: How to Vet and Visit Cylinder Neck Ring Manufacturers

- Digital Tools and Traceability for Modern Procurement

- FAQs: Cylinder Neck Ring Sourcing

- Contact Us

Choosing a cylinder neck ring supplier is a critical step in any industrial gas project. Industrial buyers today face a global market, tighter safety regulations, and higher customer expectations. Failure to specify the correct material, overlook corrosion resistance, or skip certification steps can lead to shipment delays, customs seizures, and even catastrophic safety incidents. Every decision—material, process, documentation, and logistics—affects the total cost of ownership, compliance, and customer trust.

This procurement guide will help you understand every aspect of sourcing industrial neck rings, including material selection, corrosion testing, pressure performance, logistics, global certifications, digital traceability, and efficient RFQ management. Leverage links to global standards, real-world supplier audits, and advanced digital procurement tools to ensure you always stay ahead.

Key Material, Corrosion Resistance, and Pressure Endurance Criteria

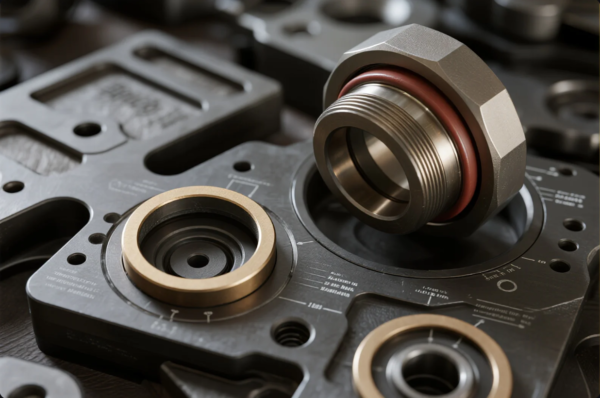

Material selection impacts safety, service life, and total cost. Cylinder neck rings are typically manufactured from:

- Carbon steel: Common for industrial and transport cylinders, offers high strength, but requires zinc or nickel plating for corrosion resistance.

- Stainless steel: Best for medical, food, and marine gases. It is highly corrosion-resistant and maintains integrity even after many years of service.

- Aluminum alloy: Used for lightweight or portable cylinders, such as in SCUBA or aviation.

Corrosion resistance is especially important for cylinders stored outdoors, used in humid, salty, or chemical-rich environments, or shipped internationally. The gold standard is performance in ASTM B117 salt spray or ISO 9227 corrosion testing.

Pressure endurance must match or exceed the working pressure of your cylinder. Check for ISO 9809, EN 1442, or DOT 3AA certification. Always require up-to-date third-party test reports with every shipment.

Compare technical details using

- AZoM for material property sheets

- Metals Supermarkets for steel grades

- Matmatch for aluminum performance data

- PPG Powder Coatings for surface protection options

| Material | Corrosion Resistance | Pressure Endurance | Key Applications |

|---|---|---|---|

| Carbon steel | Moderate | Up to 300 bar | Industrial, LPG, transport |

| Stainless steel | Excellent | Up to 300 bar | Medical, food, marine, outdoor |

| Aluminum alloy | Good | Up to 200 bar | SCUBA, aviation, portable, medical |

Lead Time and Delivery: Small Batch Trials vs Bulk Orders

Efficient procurement must balance speed and volume. Delays in trials or mass production can jeopardize new product launches, fleet maintenance, or regulatory approval windows.

Small batch trials:

- Rapid prototyping and pilot runs are critical for validating design, fit, and compliance before mass order.

- Choose suppliers with available tooling and multi-line flexibility.

- Alibaba and Thomasnet provide verified supplier reviews and lead time transparency.

Bulk orders:

- Require careful project planning and batch scheduling.

- Use digital MES or SAP SRM systems for live status.

- Select vendors with in-house customs clearance, global logistics, and clear Incoterms.

Common pitfalls to avoid:

- Underestimating tooling or sampling time

- Skipping full-scale QC checks for pilot runs

- Not securing traceable batch codes

| Order Type | Lead Time (Prime Typical) | Logistics Partners | Best Practices |

|---|---|---|---|

| Sample/small | 7–10 days | DHL, FedEx | Fast track QC, digital proof |

| Bulk/volume | 2–6 weeks | Maersk, UPS | Batch tracking, progress updates |

| Emergency | 3–5 days (in-stock) | Express air, full support | Prioritize urgent jobs, direct ship |

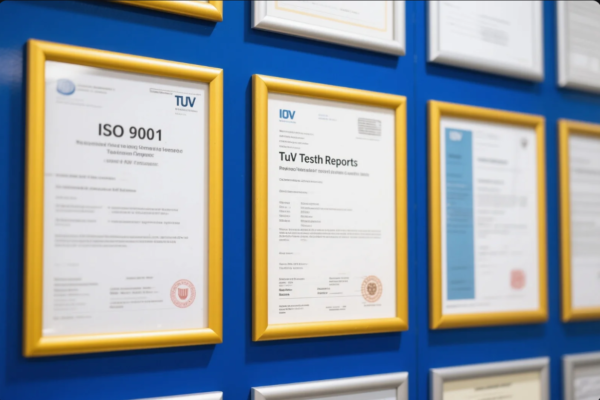

The Importance of ISO 9001, TPED, and DOT Certifications

Certification is more than a “tick the box” requirement. Lack of global approvals can result in import seizures, failed customer audits, or rejected insurance claims. The best suppliers show certificates on demand, with digital traceability and renewal info.

Key certifications for cylinder neck rings:

- ISO 9001:2015: Quality management system standard, recognized worldwide.

- EN 1442/TPED: Mandatory for cylinders/cylinder parts in EU, EEA, UK.

- DOT 3AA: US market standard for high-pressure gas cylinders and accessories.

- Third-party batch inspection: SGS, Bureau Veritas, TÜV Rheinland.

Best practices:

- Cross-check certificate numbers with issuing bodies (IAF CertSearch)

- Request batch test data, not just “sample” reports

- Audit renewal and scope dates; expired or off-scope certificates are a red flag

- Use Export.gov and CGA resources for regulatory guidance

RFQ Template: How to Efficiently Request Quotes and Evaluate Suppliers

A clear and detailed RFQ (Request for Quote) minimizes errors, accelerates negotiation, and lets you compare suppliers on a level playing field. More details also mean faster approvals from quality and compliance teams.

Sample RFQ Essentials:

- Technical drawing (attach AutoCAD or SolidWorks file)

- Material and finish (carbon steel, stainless, aluminum, plating)

- Thread standard (Cylindervalves.com)

- Working pressure and required test/certification (ISO 9809, EN 1442, DOT 3AA)

- Marking: Logo, QR code, batch number (Trotec Laser)

- Packaging (Uline, Sealed Air)

- Incoterms and payment terms (Incoterms Explained, PayPal)

- Sample requirement (Y/N), target lead time, and delivery location

Supplier Evaluation:

- Review certificates (SGS, TÜV), and recent batch test data

- Request live factory video (Alibaba Verified), on-site audit, or digital walkthrough (Thomasnet)

- Confirm digital QC reports (MasterControl)

- Check for history of export, references, and local support

Supplier Audit: How to Vet and Visit Cylinder Neck Ring Manufacturers

Conducting supplier audits—whether virtual or onsite—is crucial for risk control, compliance, and cost savings.

- Use checklists from CGA, ISO 9001 auditing tools, and Bureau Veritas guidelines.

- Review production process control, quality checkpoints, and material traceability.

- Inspect incoming material certificates (EN 10204 3.1), in-process QC, and final batch test logs.

- Verify packaging, labeling, and logistics setups in the warehouse (Sealed Air, DHL).

Digital Tools and Traceability for Modern Procurement

Advanced buyers now use digital platforms for tracking, documentation, and asset management.

- GS1 DataMatrix and QR codes for real-time asset ID and recall management.

- SAP Ariba or Oracle Procurement Cloud for multi-supplier RFQ, PO, and compliance.

- ThingWorx IoT for fleet monitoring and predictive maintenance.

- Export.gov and Customs Info for up-to-date trade and regulatory advice.

Digital traceability ensures

- Every neck ring is linked to material certificates, batch QC, and shipment records

- Instant access to test data for customer or government audit

- Streamlined recall or warranty support for high-value fleets

FAQs: Cylinder Neck Ring Sourcing

How do I verify a supplier’s ISO or DOT certification is real?

Cross-check certificates with IAF CertSearch and check for renewal dates or revocation status.

Can I order custom markings or RFID-enabled neck rings?

Yes, Prime provides laser etching, QR, and RFID as standard.

Are third-party test reports always required?

For most export and regulated markets, yes—request reports from SGS, TÜV, or Bureau Veritas.

What are the best Incoterms for global shipments?

See detailed guides at Incoterms Explained or ask your Prime account manager for recommendations based on shipment size and region.

Contact Us

Simplify your procurement, guarantee compliance, and get real-time digital support from Prime.

- Website: https://primecustomparts.com/

- Email: [email protected]

Conclusion

Procurement of cylinder neck rings is about more than price. It’s about safety, global compliance, digital traceability, and total asset value. With Prime’s experience and worldwide certifications, you reduce risk, cut lead time, and gain confidence with every order.