What is CNC Machining? A 1-Minute Guide to Precision Manufacturing

CNC machining creates custom metal/plastic parts with unmatched accuracy. In Prime’s 30-year experience, this process delivers ±0.005mm tolerances – essential for aerospace, automotive, and medical industries.

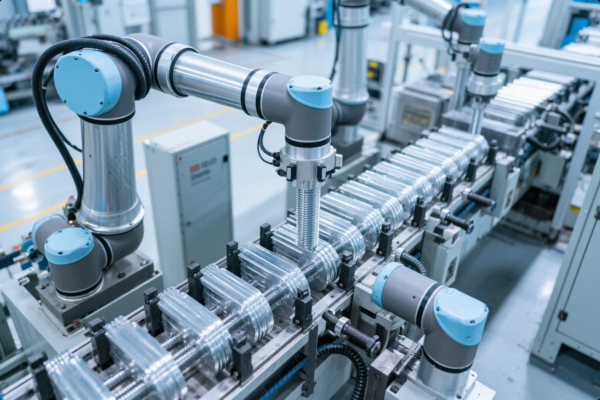

CNC (Computer Numerical Control) machining uses programmed software to automate cutting tools, transforming raw blocks into complex parts with repeatable precision (±0.005–0.1mm). Prime operates 48 advanced CNC mills/lathes producing 500+ daily components for global clients.

Here’s exactly how it works:

The CNC Process in 4 Steps

1️⃣ 3D Model Upload

- Engineers convert CAD designs into machine-readable G-code

2️⃣ Machine Setup

- Operators load material (aluminum, steel, plastic) and install tools

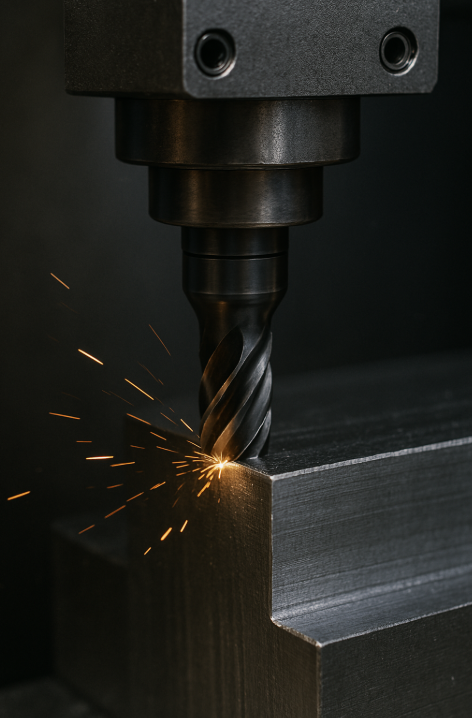

3️⃣ Precision Cutting

- Rotating end mills/drills remove material at 5,000–30,000 RPM

4️⃣ Quality Inspection

- CMMs and laser scanners verify dimensions within 0.01mm accuracy

Prime’s CNC Capabilities

| Feature | Specifications |

|---|---|

| Tolerances | ±0.005mm (medical grade) |

| Materials | 50+ metals/plastics |

| Lead Time | 3–7 days (prototypes) |

| Max Part Size | 800 × 500 × 300mm |

CNC outperforms 3D printing for strength (dense metal parts) and beats casting in precision (no shrinkage). Need complex, durable components? This is your solution.

🔧 Since 1993, Prime has machined 4 million+ CNC parts for Siemens, Boeing, and other industry leaders.