Plastic Injection Molding 101: From Raw Pellets to Finished Products

Injection molding converts tiny plastic beads into millions of identical parts with micron-level precision. At Prime, our 23 injection machines produce components for medical, automotive, and consumer industries daily.

Plastic injection molding melts polymer pellets (PP, ABS, PC), injects them into steel/aluminum molds under 20,000+ psi pressure, and ejects finalized parts in 15-90 second cycles—capable of tolerances down to ±0.05mm.

Here's how raw material becomes precision components:

1. How Are Plastic Raw Materials Selected?

Material choice determines a part’s strength, flexibility, and chemical resistance.

**Common scenarios we observe:

- Polypropylene (PP) for food containers (cheap, FDA-approved)

- ABS for automotive dashboards (impact-resistant)

- PC for medical devices (sterilizable at 120°C)**

Plastic Material Properties Comparison

| Polymer | Melt Temp | Tensile Strength | Common Uses |

|---|---|---|---|

| PP | 160-170°C | 25-40 MPa | Bottle caps, living hinges |

| ABS | 210-250°C | 40-50 MPa | LEGO bricks, car grilles |

| PC | 280-320°C | 60How Do Molding Machines Work?** |

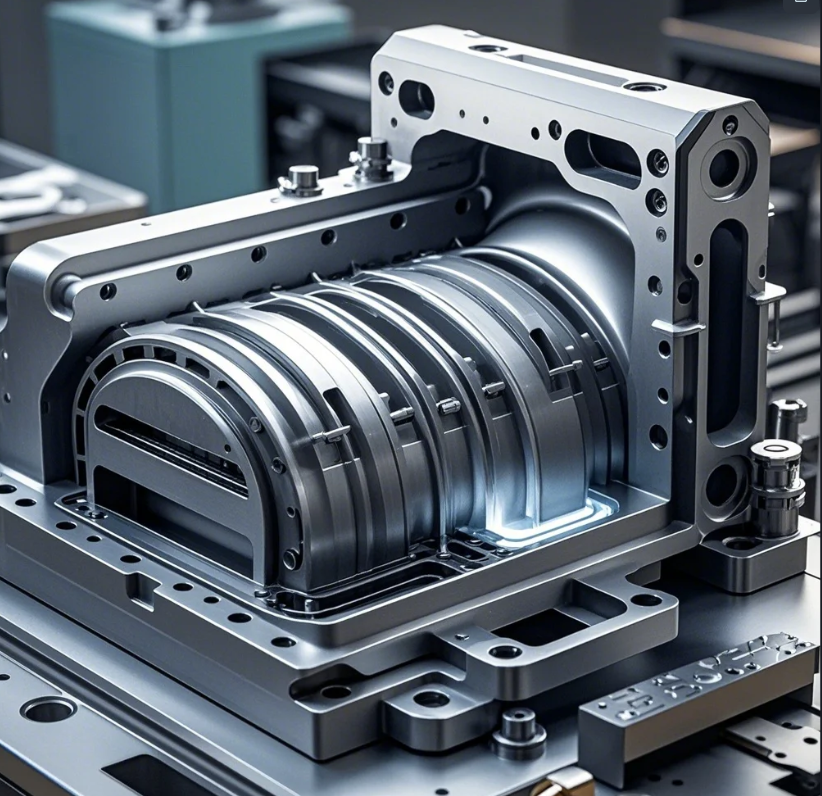

Clamping, injection, cooling, ejection—these four steps happen in seconds.

**Our 650-ton machine specs:

- 5.6-second cycles for thin-walled parts

- ±0.3°C barrel temperature control

- 3-plate molds for complex geometries

Process variations include gas-assist and overmolding**

Injection Molding Machine Types

| Type | Tonnage | Ideal For |

|---|---|---|

| Hydraulic | 50-6000t | Large parts (car bumpers) |

| Electric | 5-500t | Precision gears (<0.1mm tolerance) |

| Hybrid | 100-3000t | Energy-saving production |

3. Where Are Cooling Systems Critical?

Proper cooling prevents warping—60% of cycle time is cooling.

**Prime’s mold design rules:

- 5-15°C water channels follow part contours

- Beryllium copper inserts in hot spots

- Conformal cooling via 3D printing (cuts cycles by 25%)**

4. What Defects Occur and How to Fix Them?

Even 1°C variation causes flaws.

**Top 3 defects we troubleshoot:

- Sink marks – Increase pack pressure

- Flash – Tighten clamping force

- Short shots – Raise melt temperature

Most issues stem from improper material drying**

Troubleshooting Guide

| Defect | Cause | Solution |

|---|---|---|

| Weld lines | Low melt temp | Increase 10-20°C |

| Jetting | Fast injection | Slow first-stage speed |

| Discoloration | Overheating | Reduce barrel temps |

5. How Are Finished Parts Inspected?

Dimensional checks ensure perfect function.

**Our quality control includes:

- CMM for <0.01mm measurements

- Vision systems for surface defects

- Tensile testers validating strength

ISO 20417 standards apply for medical parts**

Conclusion

From polymer science to machine precision, injection molding transforms pellets into perfected parts. Prime’s 5-second cycle projects serve BMW, Philips, and other global brands with 0.05mm repeatability. Need molded components? We turn plastic into performance.