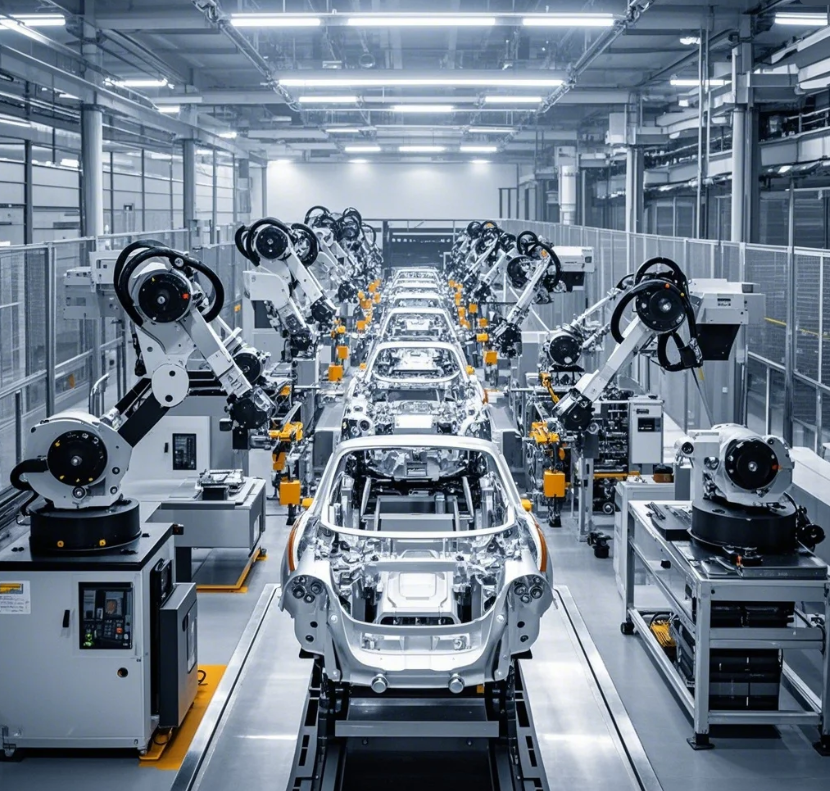

How Can Custom Metal Parts Enhance Automotive Performance and Safety?

The automotive industry relies on high-performance metal parts to build stronger, lighter, and safer vehicles. At Prime, we’ve supplied over 50 million custom metal components to global automakers, improving efficiency and crash protection.

Custom metal parts boost automotive performance by reducing weight (5-15% fuel savings), increasing strength (ultra-high-strength steel in crumple zones), and improving heat resistance (exhaust manifolds). They also enhance safety through energy-absorbing designs (crash boxes) and precision manufacturing (ABS sensor rings).

Let’s explore key applications:

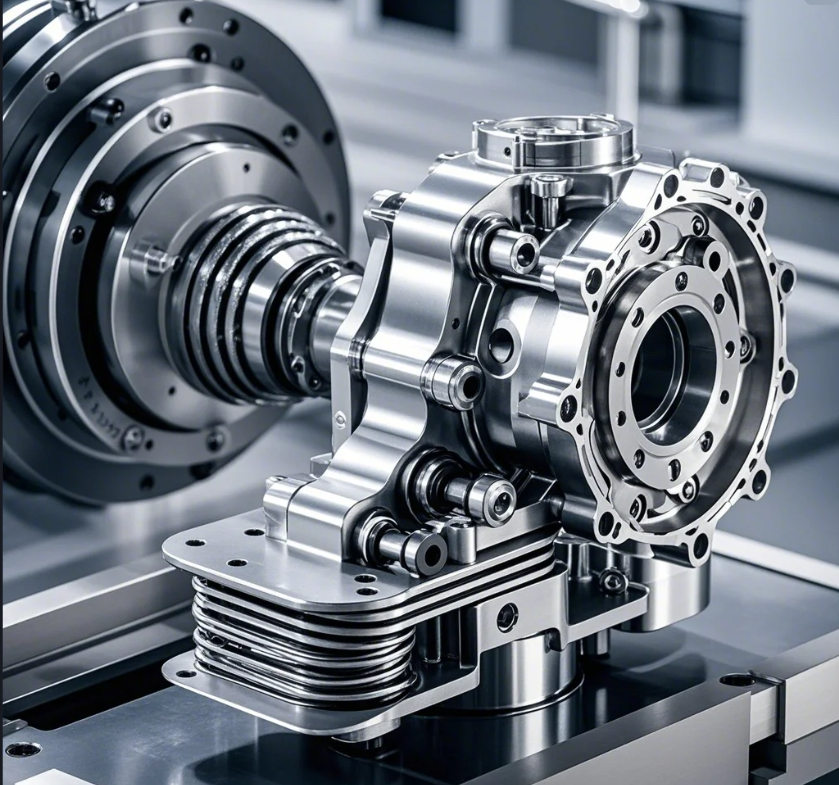

1. Engine Components: How Do Custom Metals Improve Efficiency?

High-grade alloys withstand extreme heat and friction for better fuel economy.

**What we supply to top OEMs:

- Titanium valves (40% lighter than steel)

- Forged connecting rods (handles 8,000 RPM stress)

- Aluminum alloy pistons (reduces engine weight by 30%)

These parts increase horsepower while reducing emissions.**

Materials Used in Critical Engine Parts

| Component | Material | Benefits |

|---|---|---|

| Crankshaft | 4140 Chromoly Steel | Fatigue resistance |

| Turbocharger Housing | Inconel 718 | Heat resistance (1,000°C) |

| Cylinder Head | A356-T6 Aluminum | Lightweight & heat dissipation |

2. Chassis & Suspension: Can Metals Enhance Handling?

Precision-stamped and CNC-machined parts improve ride stability.

**Our suspension system findings:

- Hydroformed control arms (20% stronger than welded versions)

- Magnesium alloy wheels (unsprung weight reduction)

- Laser-cut bushings (±0.02mm accuracy for NVH reduction)

Results: Better cornering grip and driver comfort.**

Weight Comparison: Standard vs. Custom Suspension Parts

| Part | Standard Weight | Custom Weight | Reduction |

|---|---|---|---|

| Steering Knuckle | 5.3 kg (cast iron) | 3.1 kg (forged aluminum) | 42% |

| Strut Mount | 1.8 kg (steel) | 1.2 kg (UHSS) | 33% |

3. Safety Systems: How Do Metals Save Lives?

Metals deform strategically to absorb crash forces while protecting passengers.

**Critical safety components we produce:

- Ultra-high-strength steel (UHSS) door beams (withstands 5-ton impacts)

- Precision airbag sensor brackets (0.1mm tolerance for reliability)

- Crash-severity detection brackets (controls airbag deployment timing)**

4. Braking Systems: Why Does Material Matter?

Heat dissipation and wear resistance prevent brake fade.

**Key innovations we supply:

- Vented cast iron rotors (30% faster cooling)

- Ceramic-coated calipers (reduces corrosion)

- Stainless steel brake lines (handles 3,000 PSI pressure)

Outcome: Shorter stopping distances, even in emergencies.**

Brake Rotor Material Comparison

| Material | Max Temp | Wear Life | Ideal For |

|---|---|---|---|

| Cast Iron | 500°C | 60,000 km | Daily driving |

| Carbon Ceramic | 1,200°C | 150,000 km | Performance cars |

| Drilled Stainless Steel | 700°C | 80,000 km | Track use |

5. Electric Vehicle (EV) Advancements

Lightweight metals extend battery range while maintaining durability.

**Our EV-specific solutions:

- Aluminum battery enclosures (IP67 waterproof rating)

- Copper busbars (95% conductivity for fast charging)

- Thermal-conductive cooling plates (extends battery life by 15%)

Critical for next-gen EVs.**

Conclusion

Custom metal parts make cars faster, safer, and more efficient—from forged engine components to crash-resistant frames. Prime’s ISO-certified production delivers ±0.05mm precision for global automakers. Need OEM-quality metal parts? We engineer performance.