From Prototype to Mass Production: How We Turn Custom Machine Parts Into Reality?

Launching custom machine parts from concept to full-scale production requires deep expertise. At Prime, we've guided 2,300+ clients through this journey, cutting development time by 40% while maintaining ±0.02mm tolerances.

**Our 5-phase process ensures seamless scaling:

- 3D prototyping (72-hour turnaround)

- Material validation (ISO-certified lab testing)

- Low-volume pilot runs (50-500 units)

- Production optimization (DFM analysis)

- Full-scale manufacturing (10M+ annual capacity)

Discover how we bridge the gap between idea and industry-ready parts:

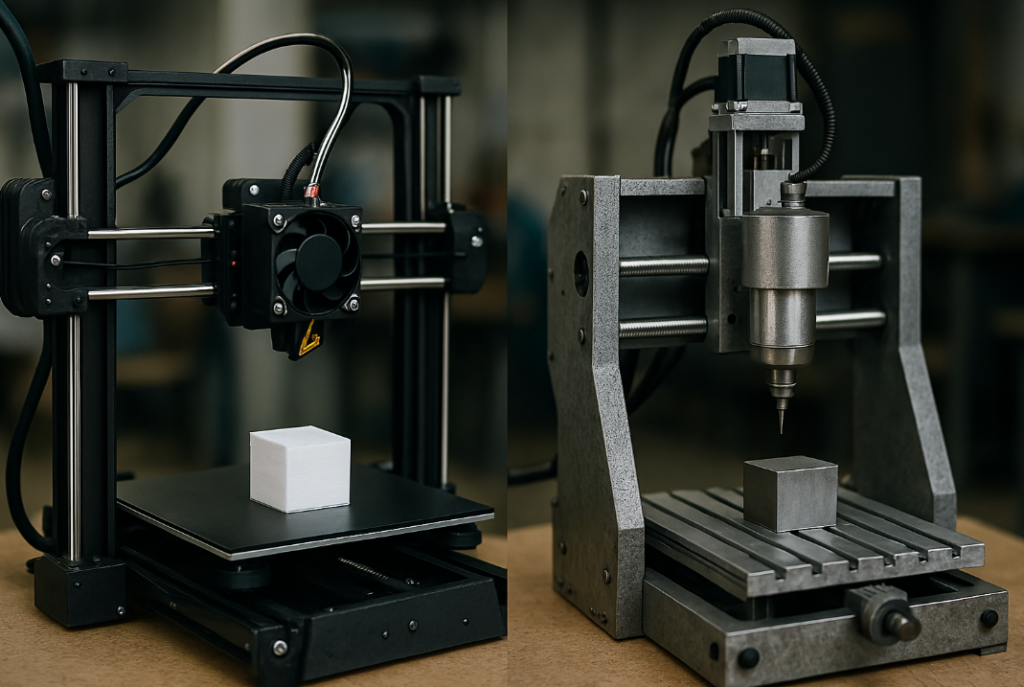

1. How Do We Transform Your Sketch Into a Working Prototype?

Fast prototyping prevents costly design flaws before tooling begins.

Our rapid prototyping toolbox:

✓ CNC machining (aluminum/steel/PEEK, 3-day delivery)

✓ 3D printing (SLS nylon, DMLS metals)

✓ Silicon molding (50-unit test batches)

Clients save $15k+ by catching errors in Phase 1.

Prototyping Method Tradeoffs

| Method | Speed | Cost per Unit | Best For |

|---|---|---|---|

| CNC Machining | 3-5 days | $$$ | Functional testing |

| SLA 3D Printing | 24 hrs | $ | Form verification |

| Vacuum Casting | 7 days | $$ | Small batches |

2. Why Does Material Selection Make or Break Your Part?

Real-world stress testing prevents field failures.

Our material validation process:

◉ Tensile/fatigue testing (simulates 5 years of use in 2 weeks)

◉ Chemical resistance baths (ASTM G31 standards)

◉ CT scanning (detects internal voids down to 0.1mm)

Recent case: Revised a client's hydraulic seal material from NBR to FKM, extending lifespan 3X.

Common Material Mistakes We Fix

| Application | Bad Choice | Our Recommendation | Why? |

|---|---|---|---|

| Food machinery | 304 Stainless | 316L SS | Acid resistance |

| High-temperature gears | POM | PEEK | 260°C capability |

| Marine bearings | Bronze | Nickel-aluminum bronze | Saltwater corrosion |

3. How Do We Bridge Prototypes to Mass Production?

Pilot runs reveal manufacturing bottlenecks before full commitment.

Our 50-500 unit pilot services:

✔ Short-run stamping (soft tooling saves $30k vs hard tools)

✔ Multi-axis CNC batches (identical to final production)

✔ In-process QC (every 10th part measured)

Result: One client avoided 12% scrap rate by catching fixture issues early.

4. What Production Tricks Cut Costs Without Sacrificing Quality?

Design for Manufacturability (DFM) optimizes every component.

Recent DFM wins:

♦ Combined 5 machined parts into 1 MIM component (-60% cost)

♦ Redesigned undercuts for simpler mold ejection (-7s cycle time)

♦ Standardized fastener sizes (-15 SKUs)

Typical savings: 18-35% per unit at scale.

Before/After DFM Comparison

| Metric | Original Design | Optimized Design | Improvement |

|---|---|---|---|

| Part Weight | 184g | 142g | 23% lighter |

| Assembly Steps | 7 | 3 | 57% faster |

| Tooling Cost | $28k | $16k | 43% cheaper |

5. How Do We Ensure Million-Unit Consistency?

Automated quality systems maintain precision at any volume.

Our mass production safeguards:

► Vision inspection robots (0.01mm repeatability)

► Statistical process control (CPK >1.67 required)

► Lot traceability (laser-marked QR codes)

Outcome: 0.12% defect rate across 8M parts/year.

Conclusion

We shepherd parts from napkin sketch to 10M-unit shipments through prototyping, testing, and smart scaling. Prime’s 20+ years of tooling expertise ensures your design hits cost, quality, and timeline targets. Ready to transform your concept? Let’s engineer efficiency.