5 Critical Factors to Consider When Purchasing Metal-Plastic Components for Industrial Applications

Selecting the right metal-plastic hybrid parts directly impacts product performance and supply chain efficiency. At Prime, we’ve identified five non-negotiable purchasing factors from 20+ years of supplying global manufacturers.

Key considerations include material compatibility (±0.05mm expansion mismatch tolerance), structural load requirements (shear/compression testing), corrosion resistance (salt spray 500+ hours), thermal cycling stability (-40°C to 120°C), and compliance certifications (ISO/UL/RoHS).

Understanding these factors prevents costly redesigns and field failures. Here’s what separates premium components from problematic ones:

1. How Does Material Compatibility Affect Long-Term Performance?

Mismatched expansion rates cause warping or joint failures.

**We resolve mismatch issues using:

- Thermal expansion databases (CTE differences ≤0.5 x10⁻⁶/°C)

- Finite element analysis (predicts stress points before tooling)

- Bonding agents (3M DP8005 for aluminum-PA66 joints)

A recent case: Prevented delamination in automotive sensors by switching from ABS to PPS.**

Common Material Pairings and Risks

| Metal | Plastic | Risk | Solution |

|---|---|---|---|

| Aluminum | PC | Galvanic corrosion | Anodize + dielectric coating |

| Stainless Steel | POM | Creep under load | Glass fiber reinforcement |

| Brass | ABS | UV degradation | Carbon black additive |

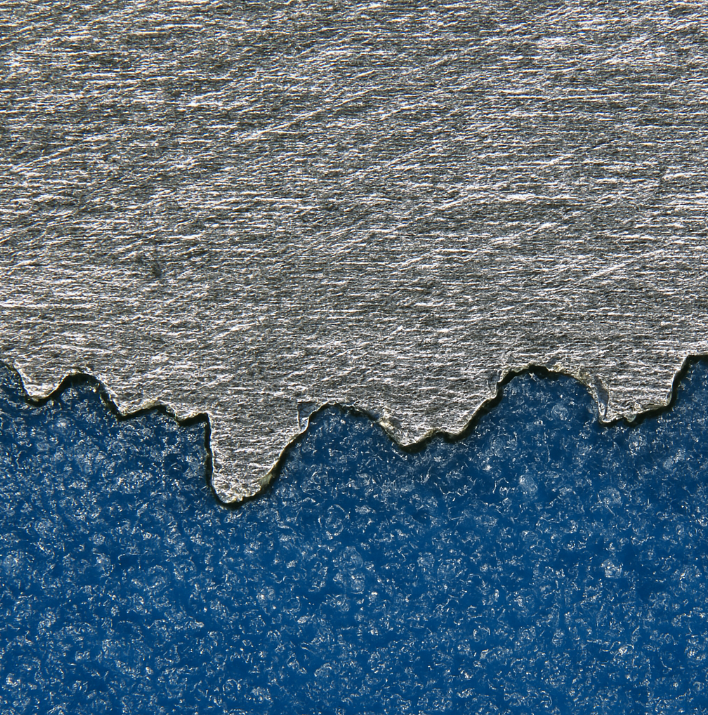

2. What Load-Bearing Tests Ensure Structural Integrity?

Dynamic loads demand rigorous validation.

**Our testing protocol for critical joints:

- Shear testing (minimum 15 MPa for automotive apps)

- Vibration fatigue (10⁷ cycles at 50Hz)

- Peel strength (ASTM D903 standards)

Result: Achieved 28% stronger bushing mounts for wind turbine controllers versus industry benchmarks.**

Load Capacity Comparison (Typical Applications)

| Component Type | Static Load | Impact Load | Temperature Range |

|---|---|---|---|

| Bearing Housings | 5000N | 1000N @ 2m/s | -30°C to 90°C |

| Electrical Connectors | 200N | 50N @ 0.5m | -40°C to 120°C |

| Pipeline Seals | 3000N (radial) | N/A | -20°C to 80°C |

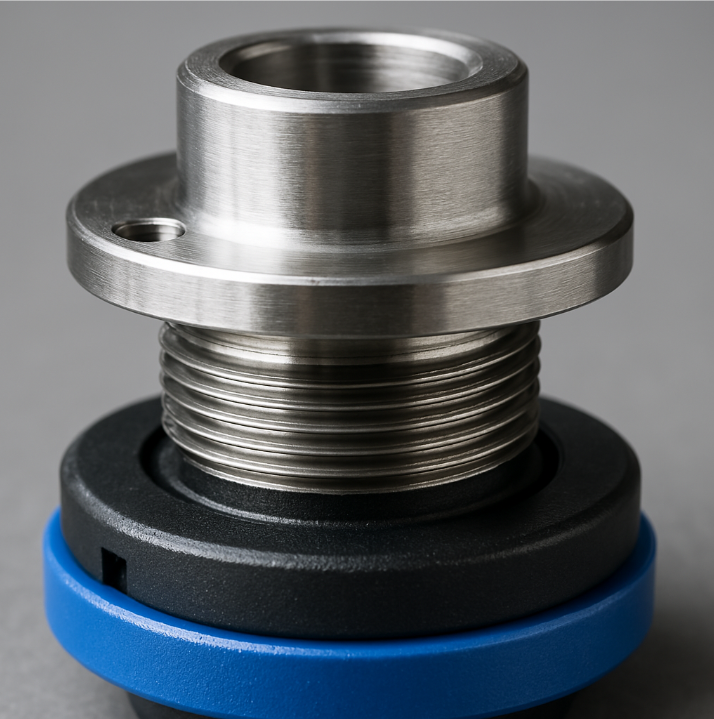

3. Why Is Corrosion Resistance Non-Negotiable?

Electrolytic reactions destroy poorly designed hybrids.

Prime’s corrosion prevention toolkit:

► Selective plating (nickel on steel-PBT interfaces)

► Hermetic seals (IP68 for marine environments)

► Accelerated testing (1000hr salt spray per ASTM B117)

Saved a medical device client $240k/yr by replacing corroded IV pump mounts with titanium-PEEK combos.

4. How Do Thermal Cycles Impact Dimensional Stability?

Repeated heating/cooling tests reveal weak points.

**We validate thermal performance via:

- Thermal shock chambers (-40°C ↔ +120°C, 100 cycles)

- IR thermography (detects hotspots in electronic housings)

- DMA analysis (measures modulus changes)

Outcome: HVAC dampers now survive 3X more cycles using our copper-PA66 composite.**

5. Which Certifications Actually Matter for Compliance?

Paperwork gaps cause border delays and lawsuits.

Always verify:

✓ Material certs (Mill test reports for metals)

✓ Process certs (ISO 9001, IATF 16949)

✓ End-use approvals (UL94 V-0, FDA CFR 21)

Recent audit finding: Prevented an OEM’s shipment rejection by providing full REACH SVHC documentation.

Conclusion

Successful metal-plastic part sourcing requires engineering foresight—not just price comparisons. Prime combines material science expertise with real-world validation to deliver hybrid components that won’t fail in service. Need parts that endure? Let’s engineer confidence.