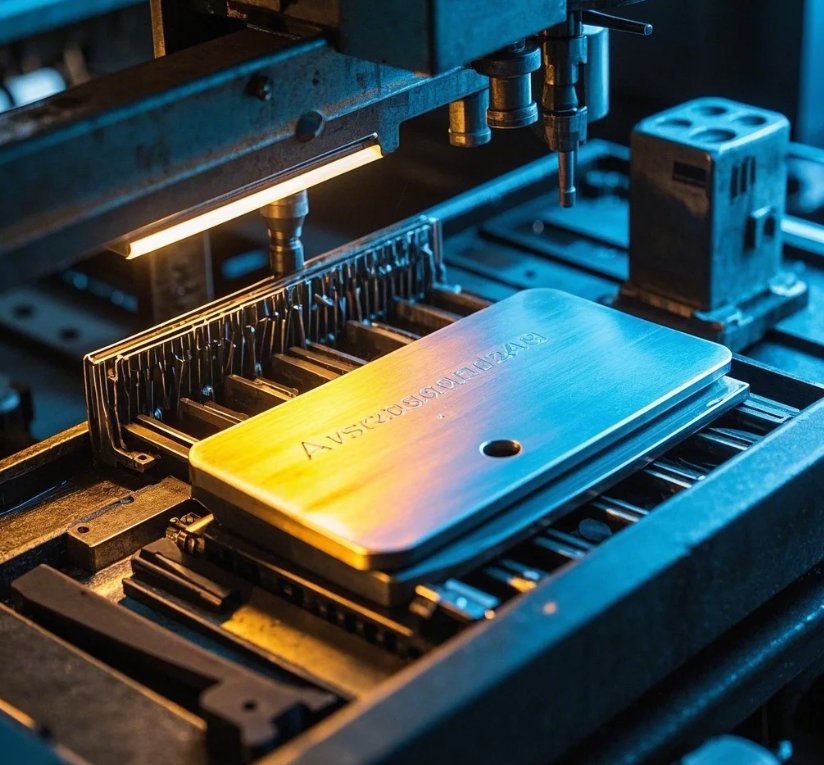

How to Stamp Metal Parts? The Complete Guide for Precision Fabrication

Metal stamping transforms flat stock into complex shapes with up to ±0.025mm accuracy at 300+ strokes per minute. Poor setup causes 70% of dimensional defects in formed parts.

Snippet paragraph: To stamp metal, first choose a press (mechanical for speed, hydraulic for force), design matched punch/die sets with proper clearance (10-15% material thickness), then feed coil stock through the tooling - typical tolerances reach IT8-IT10 for production runs.

Proper lubrication is essential - 85% of tool failures stem from galling.

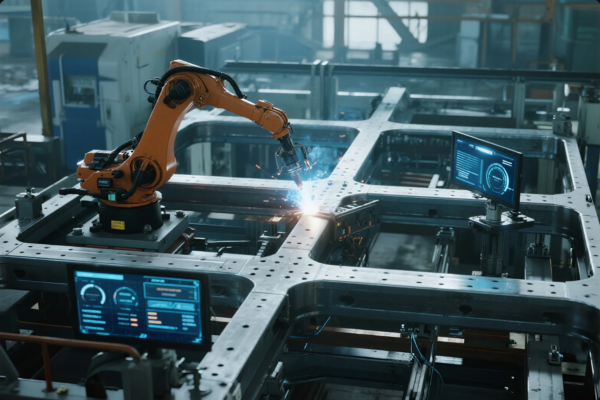

How to Select the Right Metal Stamping Press?

Press choice balances speed, force, and precision needs.

Snippet paragraph: For thin materials (<3mm), use mechanical presses (200-1,200 SPM) up to 400 tons; for thick plates (3-10mm), employ hydraulic presses (10-200 SPM) producing 2,000+ tons - servo-electric models now offer 0.01mm repeatability for delicate electronics.

Stamping Press Specifications

| Parameter | Mechanical Press | Hydraulic Press | Servo Press |

|---|---|---|---|

| Speed (SPM) | 200-1,200 | 10-200 | 20-500 |

| Force Range | 20-400 tons | 50-5,000 tons | 5-600 tons |

| Accuracy | ±0.05mm | ±0.1mm | ±0.01mm |

| Energy Use | 30-50kW | 50-200kW | 15-40kW |

| Best For | High-volume thin sheets | Heavy/thick materials | Precision forming |

Case Study: Automotive panels use 800-ton mechanical presses at 45 strokes/min for 1.5mm steel.

What Clearance Should You Use for Punches and Dies?

Material thickness determines the critical gap.

Snippet paragraph: Set punch-to-die clearance at 7-15% of material thickness (10% for steel, 12% aluminum, 8% brass). Insufficient clearance increases burrs by 300%, while excessive gaps cause rollover defects in cut edges.

Recommended Clearances (Per Side)

| Material | Thickness (mm) | Clearance (%) | Actual Gap (mm) |

|---|---|---|---|

| Mild Steel | 1.0 | 10 | 0.10 |

| Aluminum 5052 | 2.0 | 12 | 0.24 |

| Brass C260 | 0.8 | 8 | 0.064 |

| Stainless 304 | 1.5 | 15 | 0.225 |

Pro Tip: For progressive dies, add 0.005mm clearance per additional station.

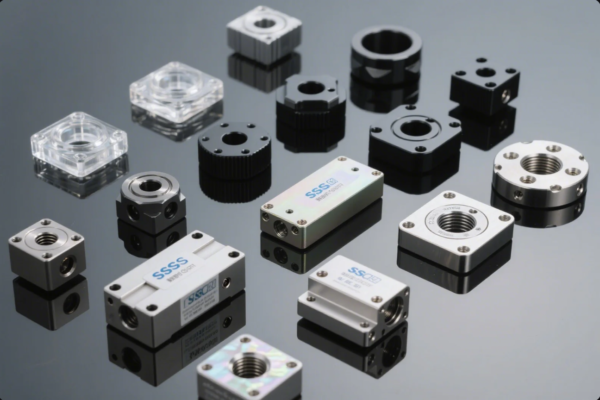

How to Design Stamping Dies?

Die engineering combines metal flow theory with practical constraints.

Snippet paragraph: Design die blocks from D2 tool steel (HRC 58-62) with corner radii of 2-3x material thickness. Include stripper plates applying 20-30% of punch force, and allow 0.1-0.3mm draft angles on formed features to ease part ejection.

Critical Die Design Ratios

| Feature | Design Rule | Example (1mm steel) |

|---|---|---|

| Punch edge radius | 5-10% of thickness | 0.05-0.10mm |

| Emboss height | ≤40% of thickness | 0.4mm max |

| Hole-to-edge distance | 1.5x thickness | 1.5mm minimum |

| Bend relief width | ≥ thickness | 1.0mm |

Red Flag: Avoid acute angles below 30° in die geometry - they concentrate stress and reduce tool life by 70%.

What Lubrication System Works Best?

The right lubricant prevents galling and reduces wear.

Snippet paragraph: Apply chlorinated oils (20-30g/m²) for steel stamping, water-soluble polymers for aluminum, and PTFE-based films for stainless steel - lubricity must balance with easy post-stamp cleaning using alkaline washes at 60-80°C.

Lubricant Performance Comparison

| Type | Friction Coefficient | Operating Temp | Corrosion Risk |

|---|---|---|---|

| Chlorinated oil | 0.05-0.08 | 20-150°C | Medium |

| Synthetic ester | 0.07-0.10 | 0-200°C | Low |

| Water-based | 0.10-0.15 | 5-80°C | Very low |

| Dry film (PTFE) | 0.02-0.05 | -20-260°C | None |

Warning: Lubricant viscosity should be 20-60 cSt at operating temperature for proper film strength.

How to Set Up a Stamping Operation?

Process parameters require fine-tuning.

Snippet paragraph: Start with 70% calculated tonnage, set press speed to 30% maximum, and adjust shut height to 0.05mm above material thickness - then gradually increase parameters while monitoring part dimensional stability (±0.02mm variation indicates proper setup).

Stamping Troubleshooting Guide

| Defect | Likely Cause | Solution |

|---|---|---|

| Excessive burrs | Worn punch/die | Replace tools or sharpen edges |

| Part sticking | Insufficient draft angle | Increase to 0.5-1.0° |

| Edge cracking | Too little bend radius | Use 4-6x material thickness |

| Dimensional drift | Uneven die wear | Resharge or adjust alignment |

Data Point: Properly maintained stamping tools last 500,000-1,000,000 cycles before requiring rework.

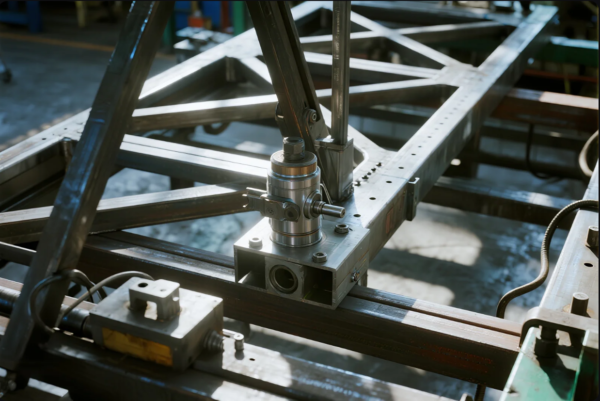

How to Choose the Right Stripper Plate?

The stripping force must overcome material springback.

Snippet paragraph: Select spring-loaded strippers with 2-3x the material thickness travel distance, applying 20-30% of punch force (e.g. 1-ton stripper force for a 5-ton punch) - polyurethane springs offer more consistent force than coil springs over time.

Stripper Plate Configurations

| Type | Force (kgf/cm²) | Advantages |

|---|---|---|

| Fixed | 50-100 | Simple construction |

| Spring-loaded | 80-150 | Adaptive to material variations |

| Pneumatic | 100-200 | Precise control |

| Hydraulic | 150-300 | Heavy material capability |

Rule of Thumb: Stripper opening should exceed material thickness by 25% for reliable part release.

Conclusion

Precision metal stamping demands carefully calculated clearances, robust tooling design, and controlled process parameters - when executed properly, it achieves 98.5%+ material utilization rates while maintaining ±0.05mm tolerances for high-volume production.