What is the first pass of a weld called?

Welding is a precise and skilled process, but many new welders often ask, "What is the first pass of a weld called?" Understanding this term is critical for mastering the art of welding and ensuring top-notch results in any welding project.

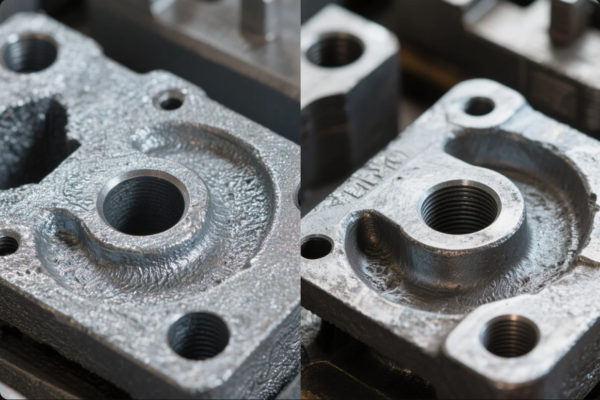

Snippet paragraph: The first pass of a weld is typically referred to as the root pass, crucial for establishing a solid foundation for the entire weld joint.

Transition paragraph: Let’s dive deeper into what exactly this first pass is and how it influences the overall welding process.

What is the first weld pass called?

The first weld pass is often called the root pass. This is the initial layer of weld metal applied to the joint, and it plays a crucial role in setting the foundation for all subsequent passes. The root pass is critical because it ensures the joint is securely bonded and that there are no gaps or weaknesses.

Why is the Root Pass Important?

The root pass is essential for the structural integrity of the entire weld. It penetrates deep into the base material, ensuring that the bond is strong and that the weld will hold up under stress. If this pass is not done correctly, it can lead to weak points that may fail under pressure. It's important to use the correct welding technique and set the right parameters to ensure a perfect root pass.

| Root Pass Factors | Description |

|---|---|

| Penetration Depth | Deep enough to bond the base materials effectively. |

| Quality of Metal Fusion | Ensures no gaps and complete fusion. |

| Heat Control | Prevents excessive burn-through or distortion. |

The root pass is not just about laying down the first layer of weld metal; it's about creating a strong, reliable foundation for all other passes to build upon.

What is the start of a weld called?

The beginning of a weld is called the start of the weld or sometimes referred to as the weld initiation. This is the moment where the welder begins applying heat and filler material to the joint.

Importance of Starting the Weld Properly

Starting the weld correctly is just as important as the first pass. A poor start can result in lack of fusion, excessive spatter, or distortion. The key to a successful weld is starting with controlled heat input and correct positioning to ensure that the weld proceeds smoothly and without defects.

The weld initiation often requires careful attention to technique and machine settings. If the welder starts the weld too aggressively, they might burn through the material or cause warping. On the other hand, starting too weakly might not create enough penetration to ensure a strong bond.

What are the passes of a weld?

In welding, the term passes refers to the layers of weld metal applied during the welding process. After the first root pass, additional passes are laid down to fill the joint and provide strength and durability. These subsequent passes are known as the fill passes and the cap pass.

Overview of Welding Passes

Each pass has a specific function:

- Root Pass: The initial weld that establishes the foundational joint.

- Fill Passes: These passes build upon the root pass and fill the weld groove.

- Cap Pass: The final pass, which smoothens the surface and provides the final finish.

The number of passes needed depends on the joint design, thickness of the material, and type of welding. For instance, in a thicker joint, multiple fill passes might be required to ensure adequate strength.

| Pass Type | Purpose |

|---|---|

| Root Pass | Establishes a strong bond foundation. |

| Fill Pass | Fills the groove and adds strength. |

| Cap Pass | Provides the final surface finish. |

By understanding the purpose of each pass, welders can better plan their approach to ensure strong, durable welds that meet industry standards.

What does FCAW mean in welding?

FCAW stands for Flux-Cored Arc Welding, a popular welding method used for its versatility and speed. In FCAW, a continuous hollow electrode wire is fed into the weld joint. The flux inside the wire protects the weld from contaminants, making it ideal for outdoor or less-than-perfect conditions.

Advantages of FCAW

One of the main benefits of FCAW is its ability to weld without the need for an external shielding gas. This makes it a preferred choice in environments where using gas might be difficult or impractical, such as outdoor or windy conditions. FCAW is known for its high deposition rates and ability to weld thicker materials quickly.

In addition, the flux-cored wire provides a self-shielding action that helps protect the weld pool from contaminants, ensuring a clean and strong weld.

| FCAW Benefits | Description |

|---|---|

| Speed | High deposition rate for faster welding. |

| Versatility | Ideal for outdoor and windy environments. |

| No Gas Required | Flux in the wire protects the weld pool. |

FCAW is a highly effective technique for achieving strong welds quickly, making it ideal for industrial applications and heavy-duty tasks.

Conclusion

Understanding the first pass in welding is critical for ensuring strong, durable joints. By focusing on a quality root pass, proper weld initiation, and following up with multiple passes, you can guarantee that your welds will withstand the test of time. If you need further assistance with welding components, our team at Prime is ready to help with high-quality welding parts and reliable solutions.

For more details on how we can assist with your industrial parts needs, feel free to reach out to Prime today. Our experienced team is ready to provide you with fast delivery and top-quality products.