How Hot Can a Single Burner Forge Get?

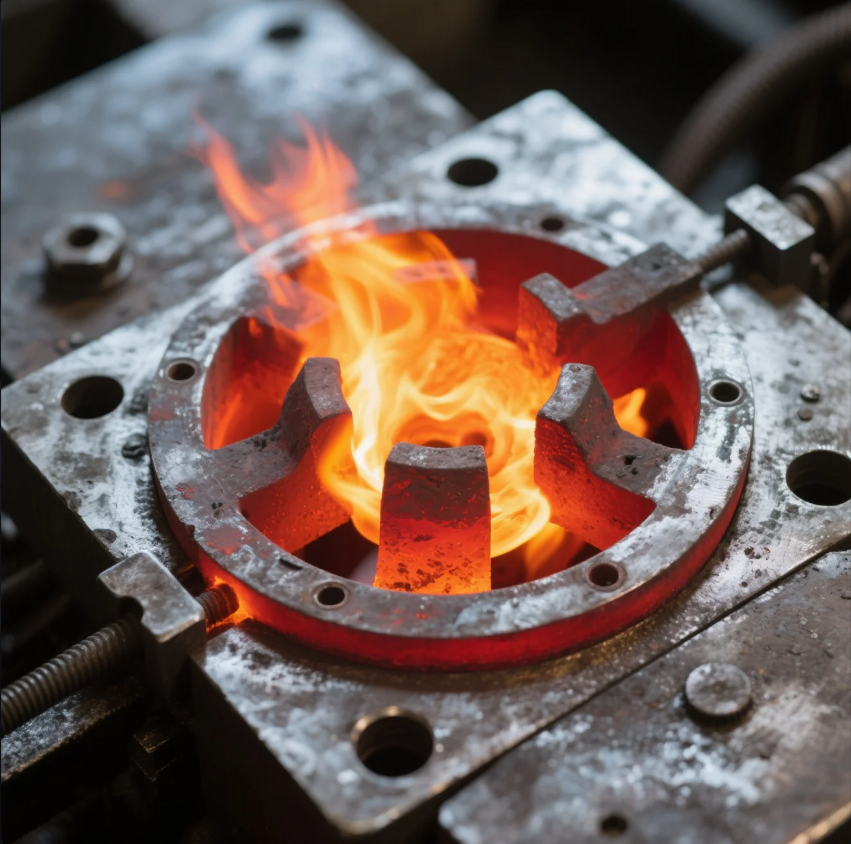

A single burner forge is a popular choice for blacksmiths and hobbyists who want to heat metal for forging or other metalworking tasks. But just how hot can a single burner forge get, and is it capable of reaching the high temperatures needed for various metalworking projects? In this article, we’ll explore the temperature capabilities of single burner forges and how they compare to other types of forges.

Snippet paragraph: A single burner forge can reach temperatures of up to 2,000°F (1,093°C), which is suitable for most forging tasks, but not high enough for melting metals like steel.

Let’s take a closer look at how hot a single burner forge can get and how you can optimize its heat for your needs.

How Hot Can a Forge Get?

A typical forge used for metalworking, such as a propane forge, can reach temperatures between 1,500°F and 2,500°F (815°C to 1,370°C) depending on the type of forge, fuel source, and airflow. The temperature range varies depending on the specific model and setup, with some forges reaching higher temperatures for more demanding tasks like forging steel.

Temperature Ranges for Different Types of Forges:

- Propane Forgeries: A well-designed propane forge can reach up to 2,000°F (1,093°C), sufficient for most types of forging, including working with mild steel and aluminum.

- Coal or Charcoal Forgeries: These can reach even higher temperatures, up to 2,500°F (1,370°C), making them ideal for forging high-carbon steels and larger projects.

For most blacksmithing and hobby forging, a forge that reaches temperatures around 1,800°F to 2,000°F is more than enough to shape steel, aluminum, and other metals.

How Hot Can a Devil Forge Get?

A Devil Forge is a popular brand of propane forges, known for their efficiency and ability to reach high temperatures. Typically, a single burner Devil Forge can achieve temperatures of 2,000°F (1,093°C) or more, depending on the design and fuel supply. This temperature is sufficient for many blacksmithing tasks, including forging steel and other metals.

Devil Forge Features:

- Single Burner Models: These can reach around 2,000°F and are great for smaller projects.

- Multi-Burner Models: These can achieve even higher temperatures, ideal for larger or more complex forging tasks.

A single burner Devil Forge is perfect for small to medium-sized projects, such as forging knives, tools, or decorative metalwork.

What is the Maximum Temperature for the Mr Volcano Forge?

The Mr. Volcano Forge is another popular brand of propane forges, known for its high heat output and versatility. Depending on the model, the maximum temperature for the Mr. Volcano Forge can reach up to 2,300°F (1,260°C). This makes it suitable for most forging tasks, including working with steel, aluminum, and brass.

Key Features of Mr. Volcano Forges:

- Single Burner Models: These forges can reach temperatures around 2,000°F (1,093°C), ideal for general blacksmithing.

- Multi-Burner Models: These can reach up to 2,300°F (1,260°C), offering higher heat capacity for larger and more demanding projects.

The Mr. Volcano Forge provides reliable temperature control, which is essential for high-precision forging tasks.

How Do You Make a Forge Burn Hotter?

If you need to make your forge burn hotter, there are several adjustments you can make to increase the temperature. Some of these modifications involve optimizing airflow, adjusting the fuel source, or using specialized materials to enhance heat retention.

Tips for Making Your Forge Burn Hotter:

- Increase Airflow: Adding a blower or fan can significantly improve the temperature of your forge. More air increases the oxygen available for combustion, leading to a hotter fire.

- Use High-Quality Propane: The quality and pressure of your propane can affect the heat output of the forge. Ensure you're using high-quality propane and maintaining the right pressure for maximum efficiency.

- Proper Insulation: Adding insulation to the interior of the forge helps to retain heat and keep the temperature consistent. Firebrick or ceramic insulation can improve heat retention and increase the overall temperature.

- Adjust the Burner: Some forges allow for adjustments to the burner, enabling you to control the fuel and air mixture. Tuning the burner for optimal performance can help achieve higher temperatures.

- Use a Refractory Lining: Adding a refractory lining (such as a high-temperature ceramic or firebrick) inside the forge can help reflect heat back into the metal, improving the overall temperature.

Increasing airflow, optimizing the fuel supply, and adding insulation are the most common ways to increase the temperature of a forge, allowing you to work with tougher metals or achieve specific forging results.

Conclusion

A single burner forge can reach temperatures of around 2,000°F (1,093°C), which is sufficient for most blacksmithing tasks, including forging mild steel, aluminum, and other non-ferrous metals. For more demanding tasks or larger pieces, forges like the Devil Forge or Mr. Volcano Forge can reach even higher temperatures. If you’re looking to increase your forge’s heat output, improving airflow, using high-quality fuel, and adding insulation are effective methods. Whether you’re forging knives, tools, or decorative metalwork, understanding your forge’s temperature capabilities is key to achieving the best results. For professional-grade forged parts and expert guidance, contact Prime today for a consultation and custom quote.