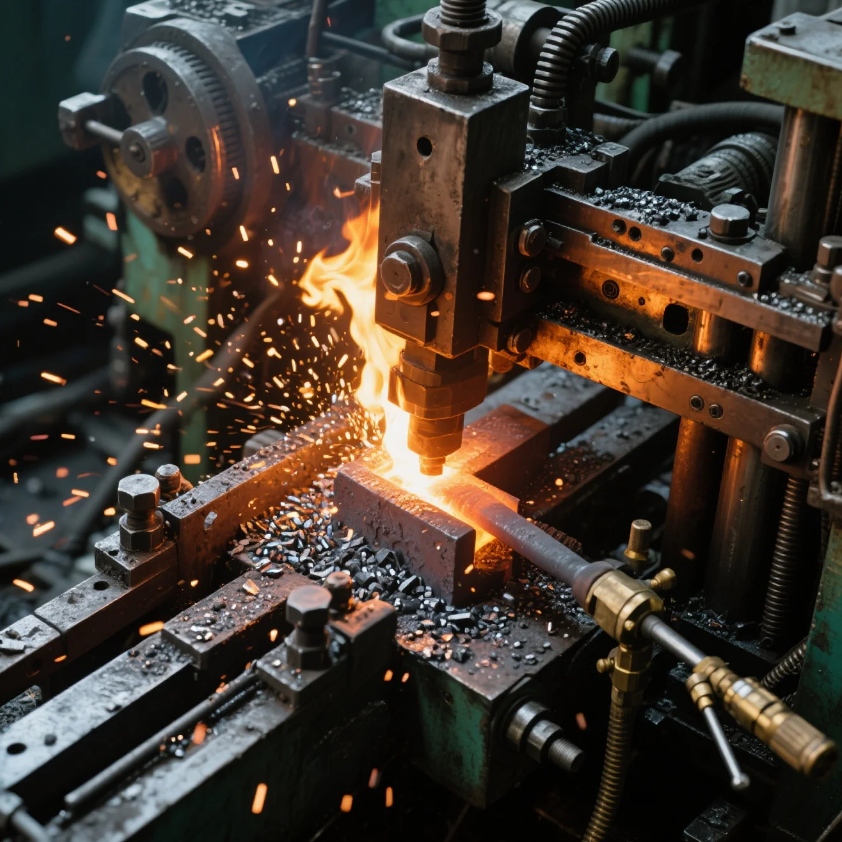

Can You Use Propane for a Forge?

Propane is a popular and efficient fuel source for forges, commonly used in blacksmithing and metalworking. It provides a clean, consistent heat that is perfect for heating metals to the temperatures necessary for forging and other metalworking tasks. In this article, we’ll explore how propane is used in forges, how long a propane tank lasts during forging, and whether propane can be used for smelting or other tasks.

Snippet paragraph: Propane is commonly used in forges because it produces high, consistent heat, making it ideal for heating metals for forging and other metalworking tasks.

Let’s dive into how propane can be used in a forge and some key questions around its efficiency and versatility.

How Long Will a 100lb Propane Tank Last for Forging?

The duration a 100lb propane tank will last during forging depends on several factors, including the size of the forge, the temperature you need to reach, and how efficiently you are using the propane. On average, a 100lb propane tank can last for approximately 8 to 12 hours of continuous forging.

Factors Affecting Propane Usage:

- Forge Size: Larger forges or multi-burner setups will consume more propane than smaller, single-burner forges.

- Temperature Setting: Higher temperatures require more fuel. If you’re heating larger pieces of metal or working with tougher alloys, the forge will burn more propane.

- Airflow and Efficiency: Properly adjusted air intake and burners will improve the efficiency of the propane, helping the tank last longer.

A typical single-burner propane forge used for small projects like knives or tools may use around 1 to 2 pounds of propane per hour, meaning a 100lb tank could last anywhere from 50 to 100 hours depending on your usage.

What Fuel Is Best for a Forge?

When it comes to choosing the best fuel for a forge, there are several options to consider, each with its own advantages and limitations. Propane is one of the most commonly used fuels in modern forges due to its ease of use, availability, and consistent heat output.

Common Fuels for Forges:

- Propane: Clean, efficient, and easy to control, propane is the go-to choice for most home forges and blacksmiths. It’s ideal for small to medium-sized forging projects and can reach temperatures around 2,000°F (1,093°C).

- Coal: Traditional and effective, coal creates high heat and is great for larger forges, but it produces more smoke and requires more maintenance compared to propane.

- Charcoal: Charcoal is similar to coal but cleaner and easier to handle. It burns hot and is often used for smaller forges or for blacksmithing projects that require high heat.

- Natural Gas: For larger industrial setups, natural gas is an efficient fuel source, but it requires a dedicated gas line.

For most home or small-scale blacksmithing, propane is considered the best fuel due to its control, ease of use, and accessibility.

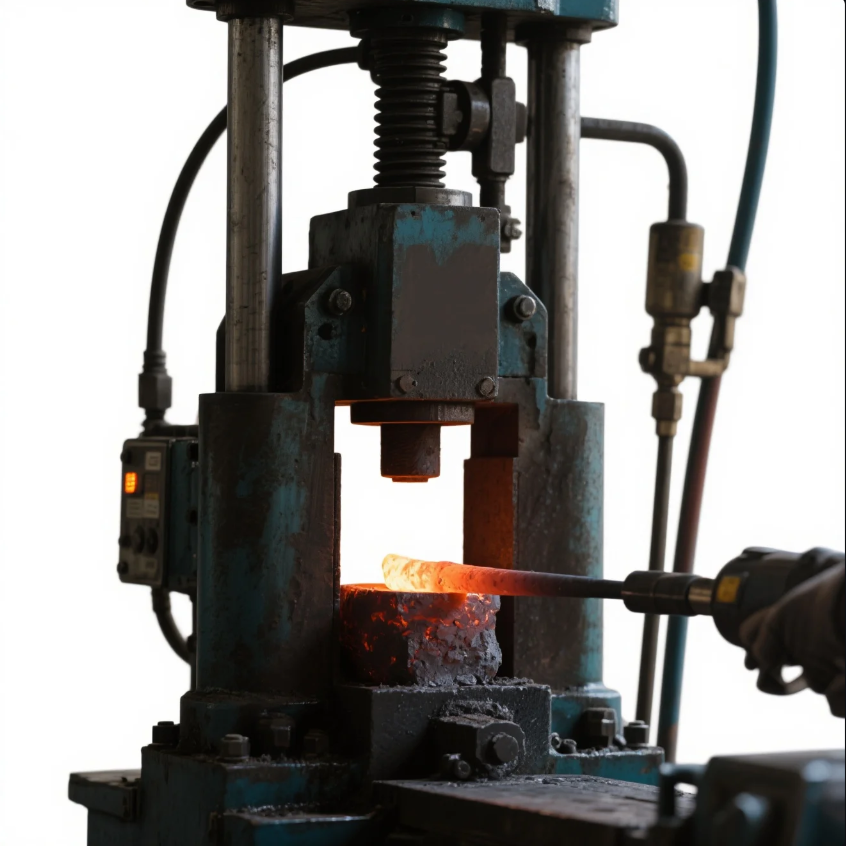

Can You Smelt in a Propane Forge?

Yes, you can smelt certain metals in a propane forge, but the temperature limitations may restrict the types of metals that can be smelted. Smelting involves heating a metal to its melting point to separate it from impurities, and this typically requires temperatures much higher than forging.

Smelting in a Propane Forge:

- Feasible for Non-Ferrous Metals: Propane forges can easily reach temperatures suitable for smelting non-ferrous metals like copper, aluminum, and brass, which melt at lower temperatures (around 1,200°F to 1,900°F).

- Difficult for Ferrous Metals: Smelting steel or iron requires much higher temperatures (around 2,500°F or more), which is generally beyond the reach of most propane forges. Specialized furnaces are typically required for smelting ferrous metals.

For smelting non-ferrous metals or small-scale smelting, a propane forge works well, but for large-scale iron or steel smelting, you’ll need a furnace capable of reaching the necessary temperatures.

Can a Propane Torch Be Used for Blacksmithing?

Yes, a propane torch can be used for blacksmithing, but it’s typically reserved for smaller, more precise tasks rather than general forging. Propane torches are commonly used in jewelry making, knife forging, or heat treating small metal pieces because they can focus a concentrated heat on a specific area.

Uses of a Propane Torch in Blacksmithing:

- Precision Heating: A propane torch is great for heating small sections of metal, such as when you need to heat treat a specific part of a tool or blade.

- Soldering and Brazing: Propane torches are commonly used for soldering and brazing metal pieces together, as well as for some light forging tasks.

- Small Projects: If you’re working with small-scale projects, a propane torch can be sufficient for heating the metal to the proper temperature for shaping or bending.

While propane torches are versatile and can be useful for smaller blacksmithing projects, they don’t produce the consistent, high heat needed for larger or more demanding forging tasks.

Conclusion

Propane is an excellent fuel for forges, offering clean, controlled heat for small to medium-sized projects. A 100lb propane tank can last for 8-12 hours depending on the size of your forge and how much fuel is consumed during use. While propane is the best fuel for most blacksmithing tasks, it can also be used for smelting non-ferrous metals in specialized setups. Propane torches are also great for precision heating and small-scale projects but are not typically used for larger forging tasks. Whether you're forging tools, knives, or artistic metalwork, propane offers an accessible, efficient solution for metalworking. For expert metalworking services and high-quality forged parts, contact Prime today to learn more and get a custom quote.