What Is CNC in Motor Parts?

Leading paragraph: Understanding CNC in motor parts is key to improving production accuracy and efficiency. CNC machining plays a crucial role in manufacturing high-performance motor components used in various industries.

Snippet paragraph: CNC (Computer Numerical Control) machining refers to the automated control of tools and machinery using a computer. It enhances precision and quality in manufacturing motor parts.

Transition paragraph: Let’s explore how CNC is used in motor parts, including its meaning, role in automotive applications, and the components it creates.

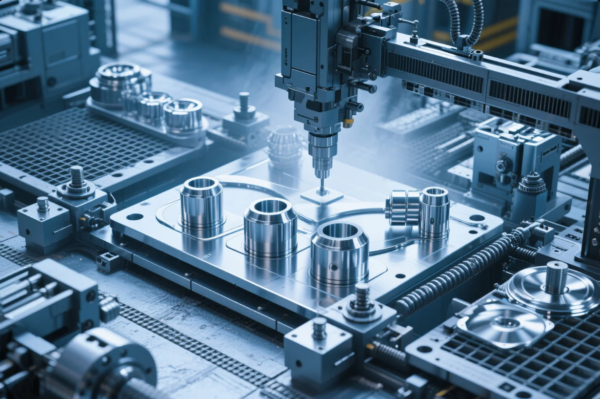

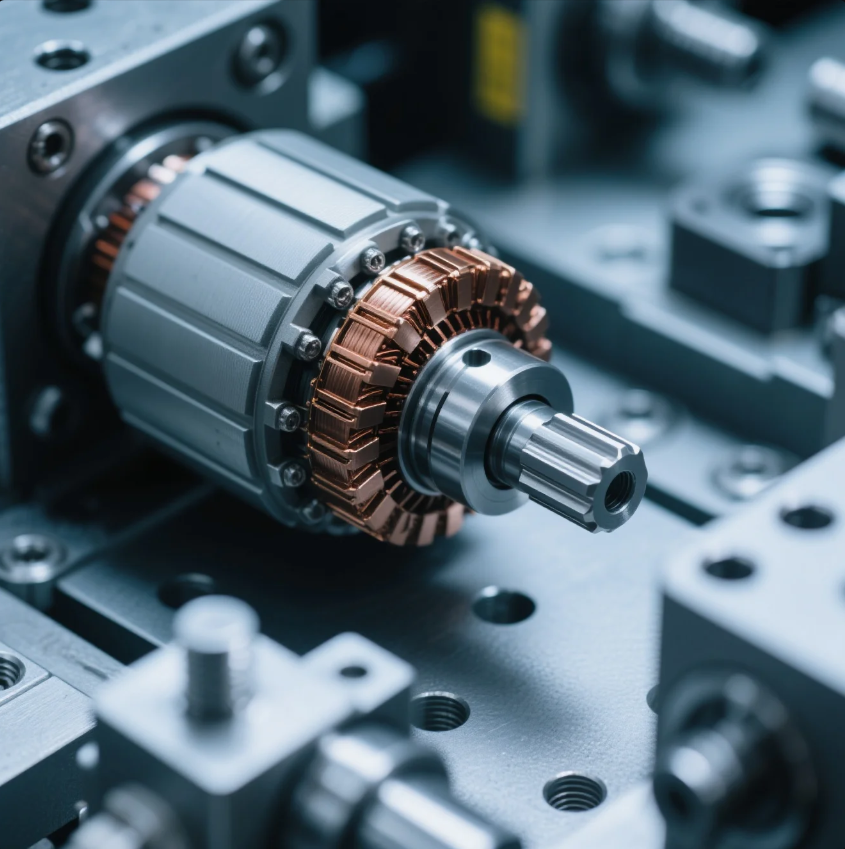

What Is CNC in Motors?

Leading paragraph: CNC in motors refers to the use of computer-controlled machinery to create precise and reliable components for motor systems. This technology has revolutionized the way motor parts are manufactured.

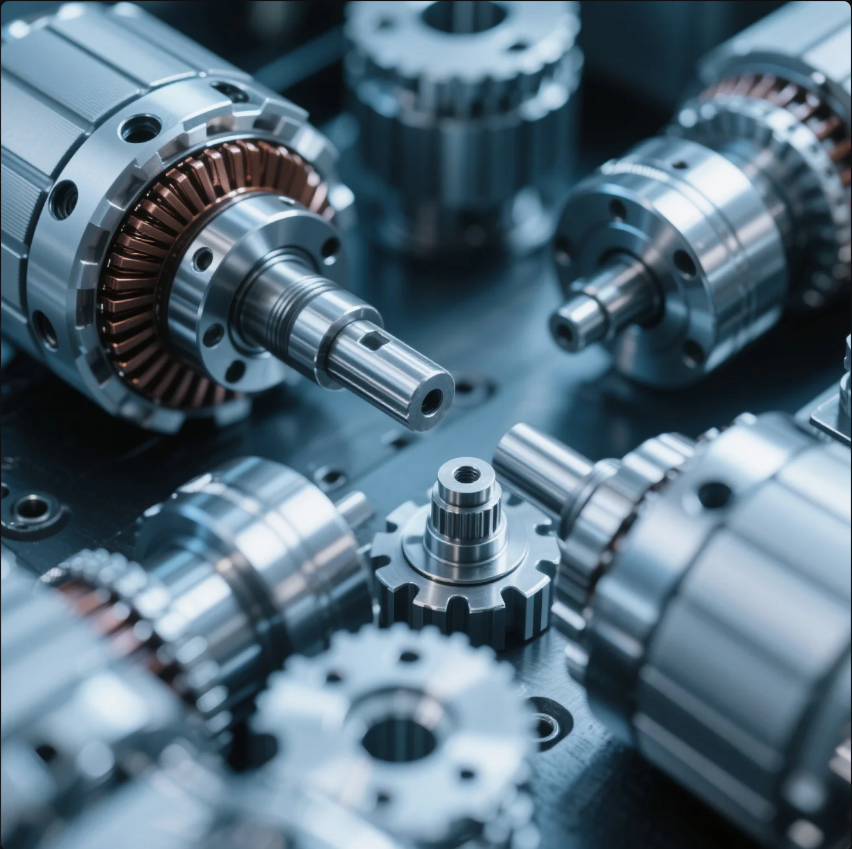

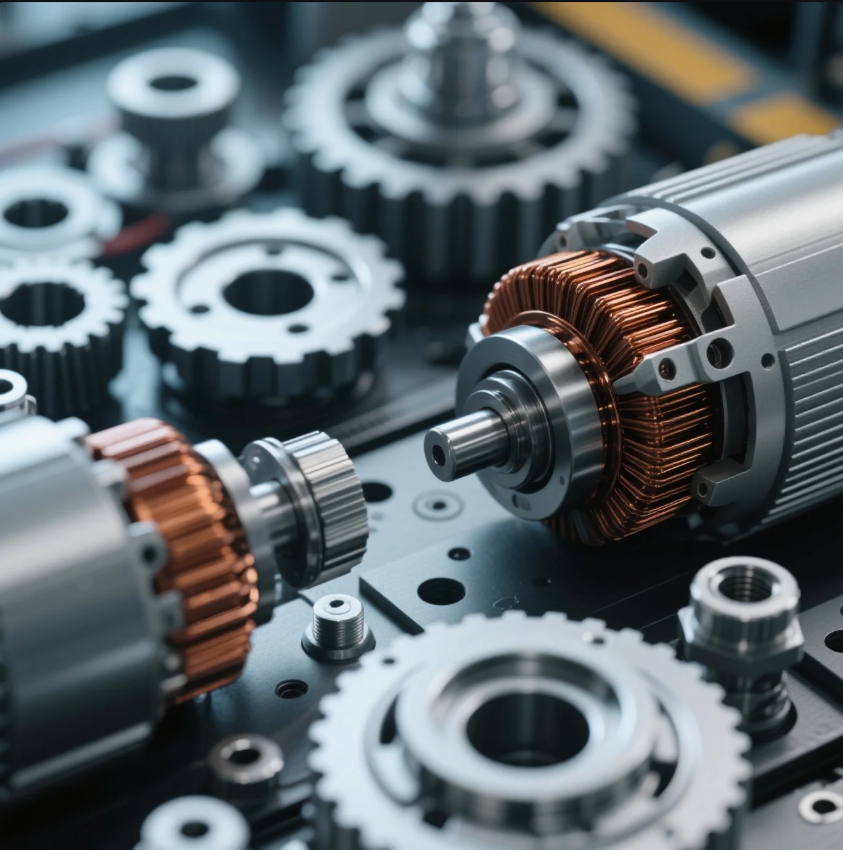

Snippet paragraph: In motor manufacturing, CNC machines are used to fabricate precise parts such as gears, shafts, and rotors. These parts must meet strict specifications to ensure optimal motor performance.

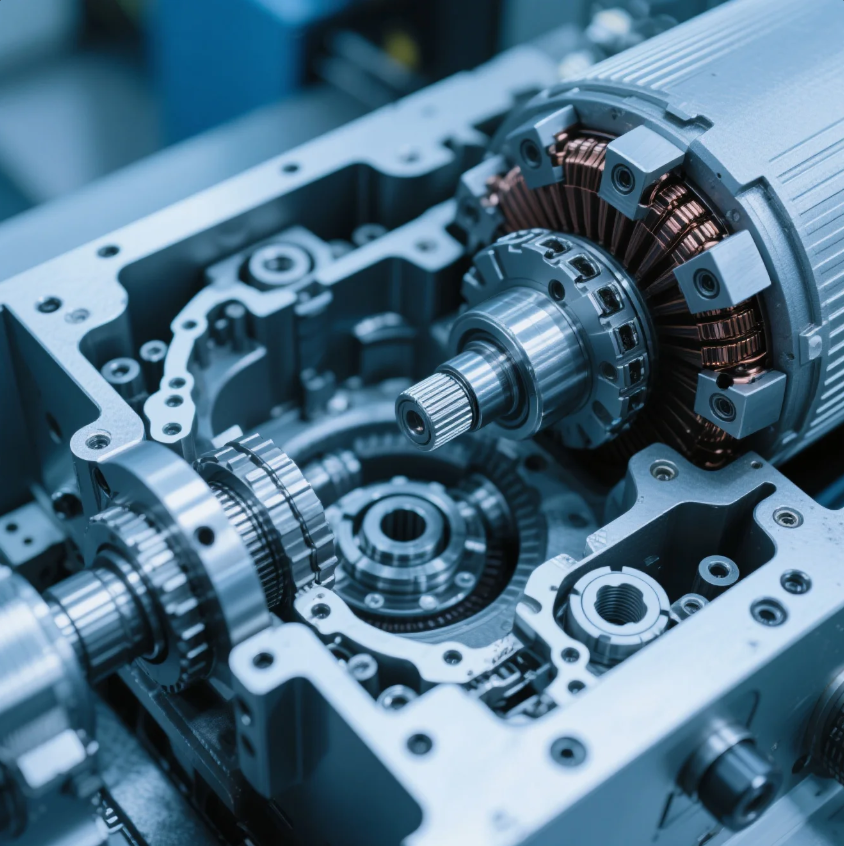

Dive-Deeper paragraph: CNC machining is vital in creating motor parts due to its ability to produce high-precision components. For example, CNC lathes and mills are used to create parts such as rotors, stators, and housings with tight tolerances. The computer controls the movement of tools, ensuring that each component is made to exact specifications. This precision is essential in motors, where even slight imperfections can impact performance or longevity.

CNC in Different Types of Motors

CNC machining is used in manufacturing parts for both electric and combustion motors. In electric motors, CNC can be used to create rotor shafts, windings, and housing components, while in combustion engines, it can be used for parts like pistons, crankshafts, and cylinder heads.

What Does CNC Mean in Automotive?

Leading paragraph: In the automotive industry, CNC technology plays a critical role in producing parts that require high precision and durability. Let’s explore what CNC means in automotive applications.

Snippet paragraph: CNC in automotive refers to the use of automated machine tools to create components like engine parts, suspension systems, and drivetrain components. It ensures consistency and precision for critical vehicle components.

Dive-Deeper paragraph: CNC machining is used extensively in automotive manufacturing for producing parts like engine blocks, cylinder heads, transmission gears, and brake components. These parts require high precision to ensure that vehicles perform safely and efficiently. CNC ensures consistency in mass production, reducing human error and increasing production speed. Additionally, CNC allows for the creation of complex geometries that would be difficult or impossible to achieve with traditional machining methods.

Benefits of CNC in Automotive Manufacturing

The use of CNC in automotive production provides several advantages, such as increased production speed, improved precision, and reduced material waste. This results in cost savings and higher-quality vehicle parts.

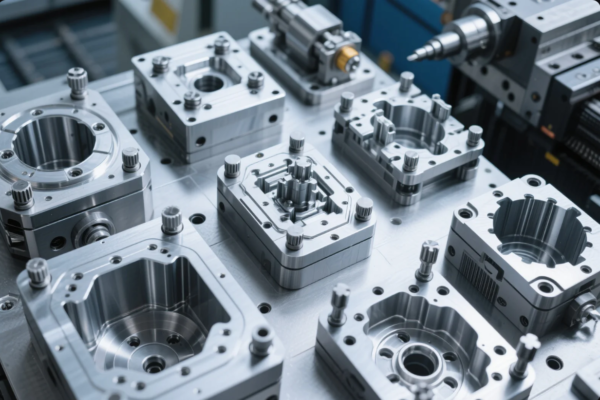

What Does CNC Stand For?

Leading paragraph: CNC stands for Computer Numerical Control. It’s a technology that uses computers to control the movement of tools in manufacturing processes. This system improves the accuracy and efficiency of producing motor and automotive parts.

Snippet paragraph: CNC is a computer-based system that directs the movement of tools and machines to create precise components. This technology has transformed manufacturing across various industries.

Dive-Deeper paragraph: CNC refers to a process in which a computer program controls machine tools like lathes, mills, and grinders. This allows manufacturers to create intricate and accurate parts with minimal human intervention. The primary advantage of CNC is its ability to produce parts that meet exact specifications consistently. In motor parts manufacturing, this technology is used to create complex components with tight tolerances, ensuring they perform optimally.

How CNC Works in Manufacturing

CNC machines operate based on digital instructions fed into the machine’s control system. These instructions direct the machine to move tools along specific paths, cutting, shaping, or drilling the material into the desired form. This process can be repeated exactly the same way for each part, ensuring consistency across all components.

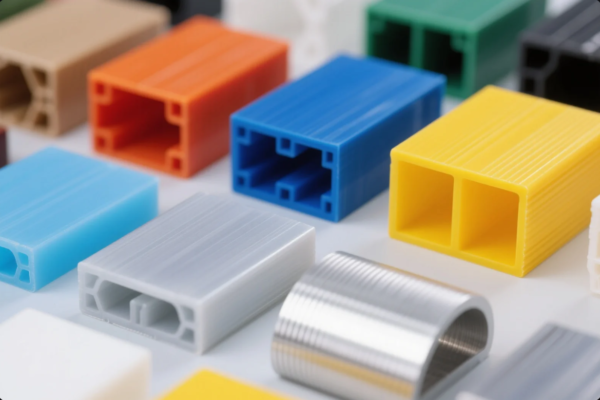

What Is a CNC Part?

Leading paragraph: A CNC part is any component created using CNC machining processes. These parts are designed to meet precise specifications and are integral to industries that require high-performance components, such as automotive and motor manufacturing.

Snippet paragraph: CNC parts are created using computer-controlled machines, ensuring high precision. These parts are commonly used in applications where accuracy is critical, such as in motors and vehicles.

Dive-Deeper paragraph: A CNC part refers to any component that has been produced using CNC machining. These parts are designed with precise measurements and tolerances, often to fit into larger systems like motors or vehicles. For example, CNC parts in a motor may include rotors, stators, and shafts, while in automotive manufacturing, they might be pistons, valves, or engine blocks. The primary advantage of CNC parts is their consistency and accuracy, which makes them ideal for high-performance applications where even slight imperfections can cause issues.

Common CNC Parts in Motors and Vehicles

Some common CNC parts in motors and vehicles include:

- Motor parts: rotor shafts, stators, armatures

- Automotive parts: crankshafts, camshafts, cylinder heads, transmission gears

Conclusion

CNC machining plays a crucial role in producing motor parts and automotive components. Its ability to create precise, high-quality parts quickly and consistently makes it an essential technology in these industries. If you’re looking for reliable and high-precision CNC parts for your projects, don’t hesitate to contact Prime. We offer fast delivery and customizable solutions for all your CNC machining needs.