What Is the Main Disadvantage of Laser Cutting?

Laser cutting is widely used in manufacturing—but what is the main disadvantage of laser cutting?

The main disadvantages include toxic material limitations, safety hazards, heat-related distortions, and high power consumption. Understanding these helps you avoid serious production errors.

If you're a buyer sourcing metal or plastic parts, knowing what is the main disadvantage of laser cutting helps you make smarter, safer decisions.

Table of Contents

- Which material should never be cut by laser?

- What is better than laser cutting?

- What is the main hazard with laser cutters?

- Do laser cutters use a lot of energy?

- Conclusion

Which material should never be cut by laser?

Many clients come to us asking what is the main disadvantage of laser cutting in terms of materials. The biggest problem is that not all materials are safe to laser cut.

PVC, ABS, fiberglass, and polycarbonate are highly dangerous under laser exposure and should never be processed this way.

These materials either emit toxic gases or reflect the laser, which can damage optics or start fires.

| Material | Laser-Safe? | Main Risk |

|---|---|---|

| PVC | ❌ | Releases hydrochloric acid gas |

| ABS | ❌ | Produces cyanide-based toxic fumes |

| Fiberglass | ❌ | Causes glass scattering and beam chaos |

| Polycarbonate | ❌ | Doesn’t cut cleanly, may melt or flare |

Understanding these material risks is essential when evaluating what is the main disadvantage of laser cutting in a real production environment.

At Prime, we have a strict screening protocol. We use only certified safe substrates, and we always recommend clients substitute harmful plastics with PETG or acrylic when possible.

What is better than laser cutting?

Clients also ask us: "If that’s what is the main disadvantage of laser cutting, then what’s better?"

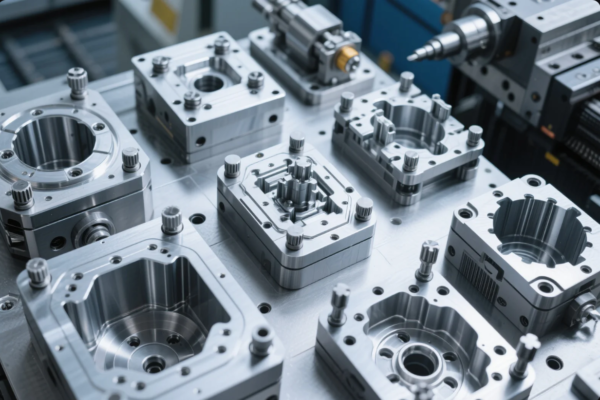

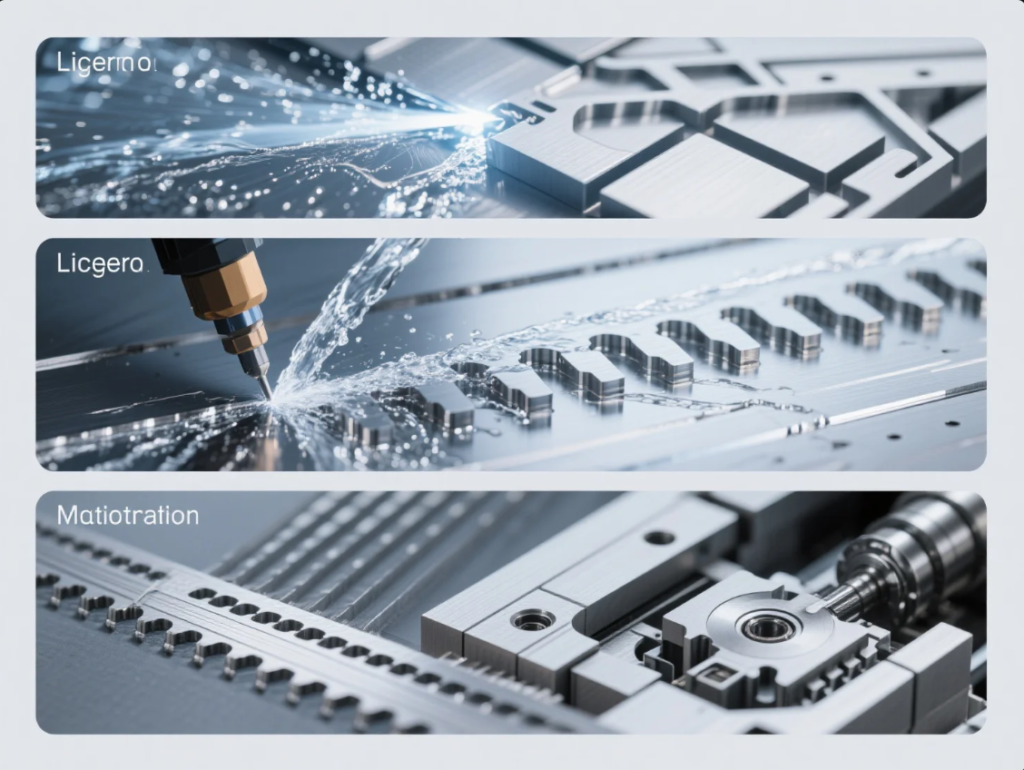

For certain projects, waterjet, CNC, stamping, or EDM are superior alternatives.

If you’re cutting thick metals or need burr-free results without heat, laser might not be the best choice. That’s when we shift to other cutting technologies.

| Method | Best For | When Laser Falls Short |

|---|---|---|

| Waterjet | Thick plates, heat-sensitive parts | Laser may burn or discolor |

| CNC Machining | 3D profiles, tapped holes | Laser can’t cut depth or threads |

| EDM | Tool steel, hardened dies | Laser can’t match this precision |

| Stamping | Mass production of simple shapes | Laser is slower for 10k+ batch jobs |

Choosing the right method avoids complications linked to what is the main disadvantage of laser cutting—especially heat distortion, edge discoloration, or safety problems.

What is the main hazard with laser cutters?

If you're still wondering what is the main disadvantage of laser cutting, it’s often tied to operator safety and machine risk.

Laser cutters expose workers to fire, toxic smoke, and eye injuries if used improperly.

Laser beams can reflect, burn, or misfire. Cheap or DIY machines pose serious risks, especially when used on improper materials.

Top hazards include:

- Toxic gas – When cutting plastics

- Flash burns – From unprotected beam exposure

- Combustion – From paper, MDF, or rubber parts

- Overheating – From poor maintenance

- Lens damage – From material flare or incorrect focus

So, what is the main disadvantage of laser cutting from a safety perspective? It's the constant risk of injury or damage when safety systems fail or training is ignored.

At Prime, every laser system includes:

- Full fume extraction

- Fire detection shutdown

- CE-compliant optical shielding

- ISO-standard operator training

Clients rely on us for clean, certified, and secure production. That's the Prime difference.

Do laser cutters use a lot of energy?

Yes—and that’s another valid answer to what is the main disadvantage of laser cutting?

Industrial laser systems consume high electricity, especially at 3kW and above. Energy costs add up fast.

Energy draw breakdown:

| System | Daily Use (10h shift) | Monthly Usage | Notes |

|---|---|---|---|

| 3kW Fiber Laser | 50–60 kWh | \~1,500 kWh | Highly efficient |

| 6kW CO₂ Laser | 90–120 kWh | \~3,000 kWh | High power, more heat |

| Cooling Systems | 15–30 kWh | \~800 kWh | Required for beam stability |

| Air Compressors | 20–40 kWh | \~1,000 kWh | Needed for clean cuts |

For clients running 24/7 shops, this adds thousands in utility bills. If your volumes are low or your cuts are infrequent, it may be more economical to outsource to a provider like Prime instead of operating your own laser.

We optimize energy use by:

- Running nesting software to minimize cut time

- Auto-shutting idle beams

- Using efficient fiber systems

- Grouping orders by material and gas type

Knowing energy impact is key when clients ask what is the main disadvantage of laser cutting in large-scale operations.

Conclusion

So, what is the main disadvantage of laser cutting? It’s a combination of material restrictions, safety concerns, energy costs, and heat distortion. These don’t cancel out the benefits—but they matter when selecting the right process for your project.

Need expert help with your next laser job?

Talk to Prime for a free review, expert quote, and safe material guidance.

- 🌐 Website: https://primecustomparts.com

We answer more than just what is the main disadvantage of laser cutting—we help you solve it.