Are 3D printed metal parts strong?

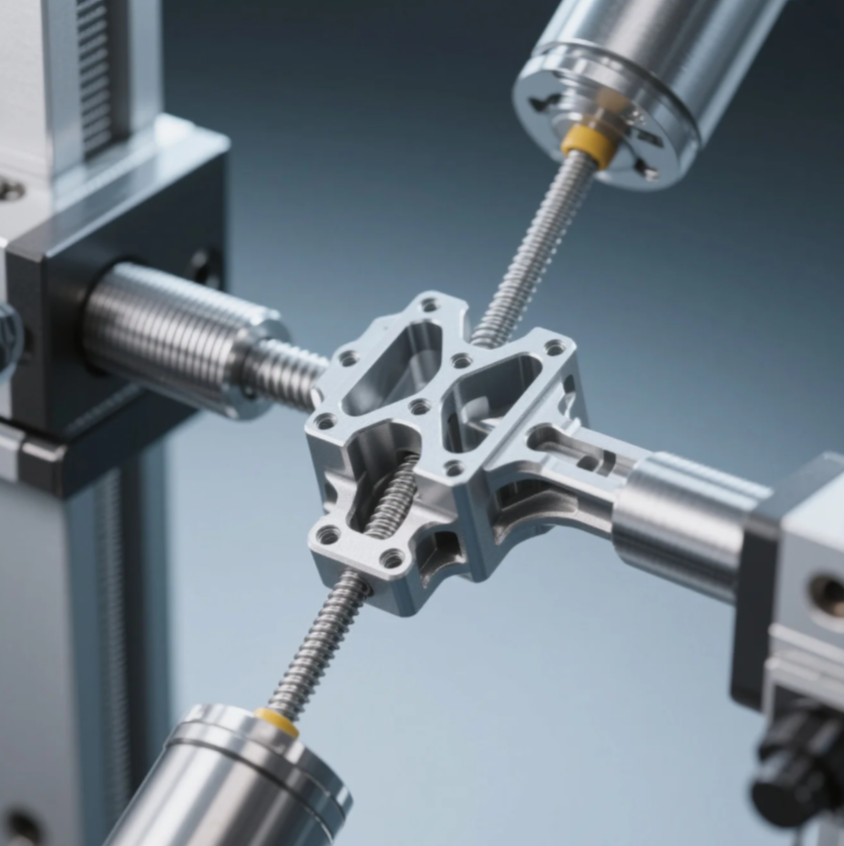

Image: A laser-sintered stainless steel bracket undergoing structural load testing at Prime.

Engineer (Prime): A lot of clients ask us this: “Are 3D printed metal parts actually strong enough for real-world use?”

Buyer: That’s exactly my concern. We’re considering metal AM for a lightweight bracket, but strength is critical. What should we expect?

Engineer: Great question. Strength can vary—but with the right process and post-treatment, metal printed parts can rival cast or even machined components.

How strong is 3D printed metal?

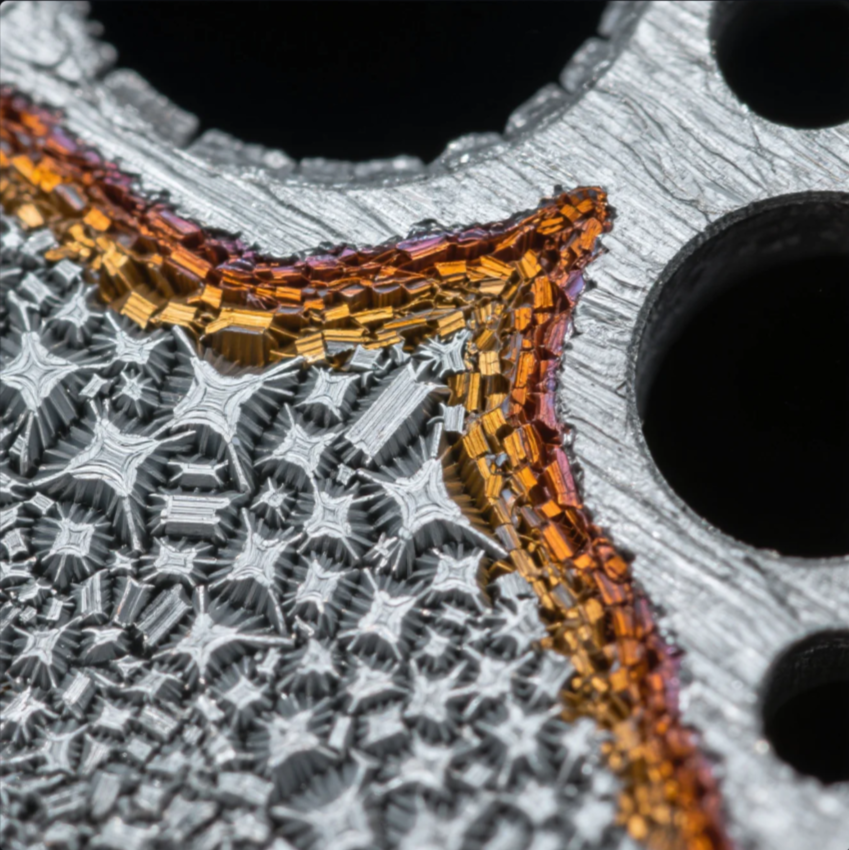

Image: A microscopic cross-section showing the microstructure of a DMLS stainless steel part.

Buyer: So how strong are we talking here? Any actual numbers?

Engineer: Sure. Tensile strength ranges from 500 to 1300 MPa depending on the alloy and printing process.

| Material | Process | Typical Strength (MPa) |

|---|---|---|

| Stainless Steel | DMLS | 600–1000 |

| Titanium Ti64 | EBM | 900–1150 |

| Aluminum (AlSi10Mg) | SLM | 320–400 |

| Inconel 718 | DMLS | 1000–1300 |

Engineer: At Prime, we use CT scans and destructive testing to validate structural performance when strength is critical.

Buyer: Impressive. So it’s not just for show pieces.

Engineer: Exactly. With the right settings, it’s production-grade.

Is 3D printed metal as strong as cast?

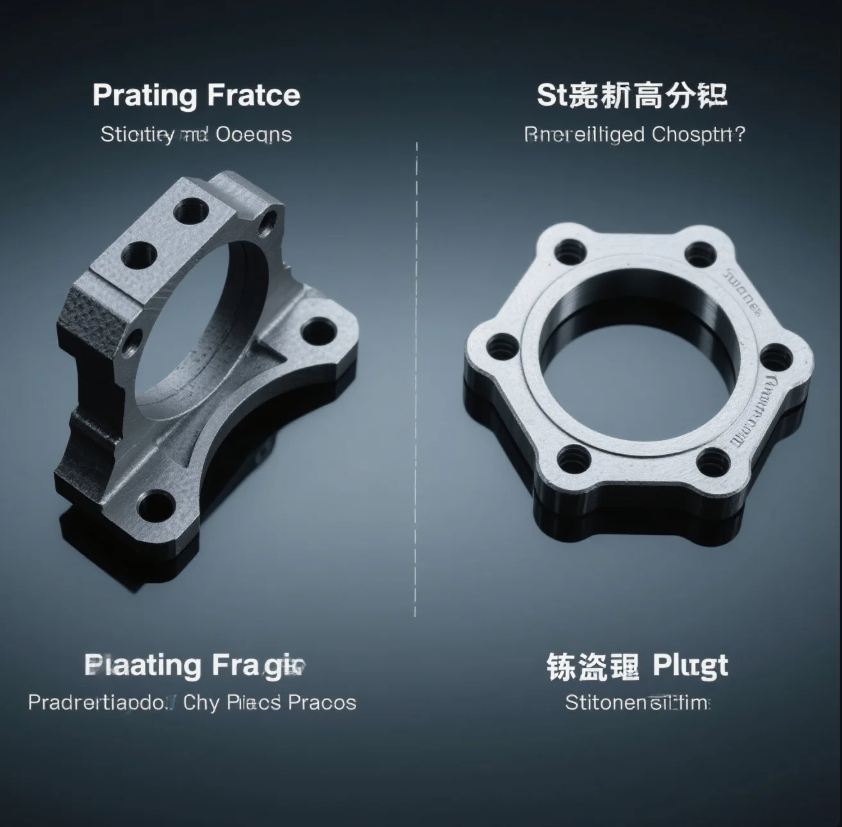

Image: Identical part geometry produced via casting and metal 3D printing, tested side by side.

Buyer: How does it compare with cast parts in terms of durability?

Engineer: Good question. With heat treatment and optimized parameters, printed parts can match or outperform cast ones.

Buyer: Any drawbacks?

Engineer: Sure—metal prints can have micro-porosity if the process isn’t tuned well. But casting has its flaws too: shrinkage, tooling variation, etc.

Buyer: So when would you use printing instead of casting?

Engineer: When you want:

- Fast iterations

- Complex internal features

- Low-to-mid volumes

- No mold costs

Prime often recommends DMLS for these cases.

Summary: If you manage the post-processing well, 3D printed parts can absolutely compete with casting.

Can 3D printed parts be strong?

Image: A lightweight bracket printed using titanium, designed using generative optimization.

Buyer: I’ve heard you can optimize printed parts for strength. Is that true?

Engineer: Absolutely. With additive manufacturing, you’re not bound to traditional design limits.

You can:

- Add strength only where needed

- Use internal lattices or trusses

- Reduce weight while maintaining stiffness

- Apply FEA to iterate faster

Buyer: And this works for metal, not just plastic?

Engineer: Yes—especially in aerospace and robotics. Prime helps clients apply DfAM (Design for Additive Manufacturing) principles to maximize both strength and efficiency.

Summary: Properly designed printed parts can outperform traditional ones in both weight and stiffness.

Is 3D printed metal as strong as forged?

Image: Forged metal grain alignment vs. 3D printed isotropic structure.

Buyer: How does 3D printing compare to forged metal? I know forging is strong.

Engineer: Forging still wins for ultimate strength—thanks to directional grain alignment and compression. But printed parts can come close if post-processed correctly.

Buyer: So you’d never use printed parts for load-bearing components?

Engineer: Not true. We often suggest:

- Printing for rapid prototyping or complex shapes

- Forging or CNC for high-volume, high-impact use

- Hybrid workflows—print, test, then forge final version

Buyer: Got it. It’s about matching method to purpose.

Engineer: Exactly. And we help clients choose based on load requirements, cost, and timeline.

Frequently Asked Questions (FAQ)

❓ Do 3D printed metal parts require heat treatment?

Yes.

Stress relief or HIP treatment helps maximize mechanical properties.

❓ Can I use 3D printed titanium in aerospace?

Absolutely.

It’s already used in satellites, rockets, and UAV components.

❓ Is printing better than CNC machining?

Depends.

Printing is better for complex shapes and short runs. CNC wins for accuracy and volume.

❓ Are printed metal parts reliable under load?

If processed correctly, yes.

That’s why Prime includes test reports and quality verification.

Conclusion

Buyer: So, are 3D printed metal parts strong enough for real use?

Engineer: In most cases—yes. They’re already used in planes, implants, tools, and robotics. But material choice, geometry, and process settings all matter.

Buyer: Good to know. I think we’ll explore a pilot run with printed titanium brackets.

Engineer: Sounds great. We can help you test, refine, and scale production.

Interested in testing metal 3D printing for your project?

Contact Prime for a free consultation, strength evaluation, and design review.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com