Can you 3D print metals at home?

Image: A desktop 3D printer using metal composite filament, installed in a home garage environment.

Engineer (Prime): You’re thinking about printing metal parts at home?

Buyer: Exactly. I’ve been using FDM printers for plastic prototypes, and I’m wondering—can you 3D print metals at home?

Engineer: Great question. Short answer? Kind of—but not in the way most people expect. True metal 3D printing still requires serious equipment, safety systems, and post-processing. Let’s break it down.

Can a 3D printer print metal at home?

Buyer: So what’s possible with my desktop setup?

Engineer: If you’re using an FDM printer, you can work with metal-filled filaments—basically plastic mixed with copper or steel powders. They look metallic but are mostly polymer.

Buyer: What about real metal?

Engineer: You’d need filaments like BASF Ultrafuse 316L. But after printing, the part needs to be sent to a debinding and sintering facility. That’s not something you can do in your garage safely.

Summary: You can simulate metal prints at home, but true metal printing needs industrial equipment.

Can normal 3D printers print metal?

Buyer: So, my Creality or Prusa can’t print actual steel or titanium?

Engineer: Correct. Standard FDM or SLA printers can’t melt or fuse metal. You’re limited to:

- Plastic composites with metal powders

- Wax patterns for casting

- Sinterable filaments (with external help)

Let’s compare:

| Printer Type | Real Metal Output? | Notes |

|---|---|---|

| FDM (home use) | ❌ No | Only for bronze-fill or steel-fill plastic |

| SLA/DLP | ❌ No | Good for molds or lost-wax casting |

| Metal FFF + Sinter | ✅ Yes (indirect) | Needs third-party sintering service |

| DMLS/SLM | ✅ Yes (pure metal) | Requires \$250K+ setup, gas & laser control |

Buyer: So I can make a mold at home, but not the final metal part?

Engineer: Exactly. For real strength and density, we use SLM or DMLS at Prime.

How much does a 3D metal printer cost?

Buyer: If I wanted to do this myself, how much would it cost?

Engineer: Entry-level metal printers start at \$50,000—and that’s not including:

- Inert gas chambers

- Sintering furnaces

- Filtration for combustible powder

Full industrial systems like EOS or Renishaw run \$250,000 to \$1M+.

| Printer Model | Estimated Price | Requires… |

|---|---|---|

| Desktop Metal Studio System | \$50,000–\$120,000 | Furnace, training, ventilation |

| EOS M290 (DMLS) | \$350,000+ | Full lab setup |

| SLM 280 (Selective Laser) | \$500,000–\$900,000 | Industrial powder handling system |

Buyer: That’s not exactly hobbyist-friendly.

Engineer: Right. Most of our small-batch clients just send their CAD files to us, and we handle the rest.

Are there 3D printers that can print metal?

Buyer: So metal 3D printing definitely exists—it’s just not for the average person?

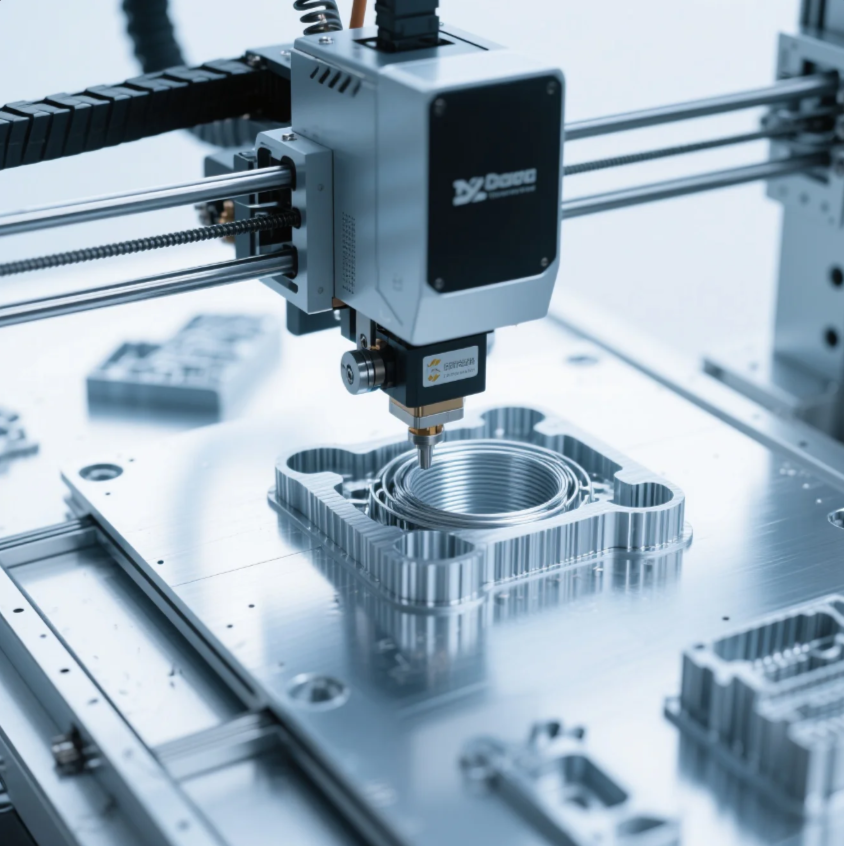

Engineer: Exactly. Industrial metal printers use:

- Lasers or electron beams

- Inert gas enclosures

- Powder beds with micron-level control

They’re used for:

- Aerospace brackets

- Medical implants

- Lightweight structural parts

At Prime, we offer metal printing in stainless steel, titanium, Inconel, and aluminum—all from ISO-certified labs.

Buyer: That’s what I’d need for strong, functional parts?

Engineer: Yes. You could use your home setup for mold patterns, and we’d take care of the high-performance end.

Frequently Asked Questions (FAQ)

❓ Can I buy a cheap metal 3D printer?

Engineer: Not for real metal. Low-cost options only simulate the look, not the strength.

❓ Can I cast metal from a 3D printed pattern?

Engineer: Absolutely. Many clients use PLA or wax prints for lost-wax casting, then pour real metal.

❓ Is it safe to use metal powder at home?

Engineer: Not really. The powder is flammable, and lasers or sintering require industrial safety measures.

❓ What’s the best workaround for home users?

Engineer: Print a mold or pattern at home. Send it to Prime for casting or laser metal printing.

Conclusion

Buyer: So, can you 3D print metals at home?

Engineer: Only partially. You can print simulations or casting molds. But for actual metal parts with industrial strength, you need commercial equipment—or a reliable partner.

Buyer: I guess outsourcing to a company like Prime makes more sense.

Engineer: Exactly. We’ll help you with material selection, metal printing, post-processing, and even finishing.

Need real metal parts, without spending \$200,000 on equipment?

Contact Prime for fast, affordable, and certified metal 3D printing.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com