Can you injection mold with a 3D printer?

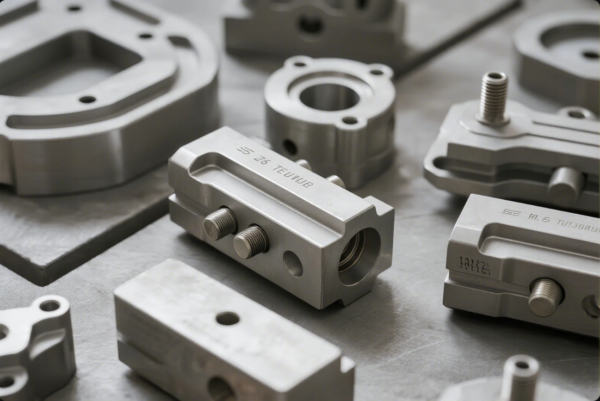

Image: Prime’s prototype mold insert created using a high-resolution industrial 3D printer.

Trying to reduce mold costs or speed up prototyping?

Can you injection mold with a 3D printer? The answer is yes—for certain applications. 3D-printed molds can work in low-pressure or short-run injection molding projects, especially during prototyping. However, material strength, heat resistance, and production volume must be carefully considered.

The growing use of additive manufacturing in mold-making has changed the way engineers approach early-stage development. But does that mean printed molds are ready for high-output injection lines? This article explores what’s possible—and what isn’t—when using 3D printers for molding tools.

Can I use a 3D printer to make molds?

Can you injection mold with a 3D printer in real production scenarios? Yes, but with strict limitations.

3D printers can create mold inserts for short-run injection molding, using specialized high-temperature resins or engineering-grade filaments. These are ideal for prototyping and functional testing.

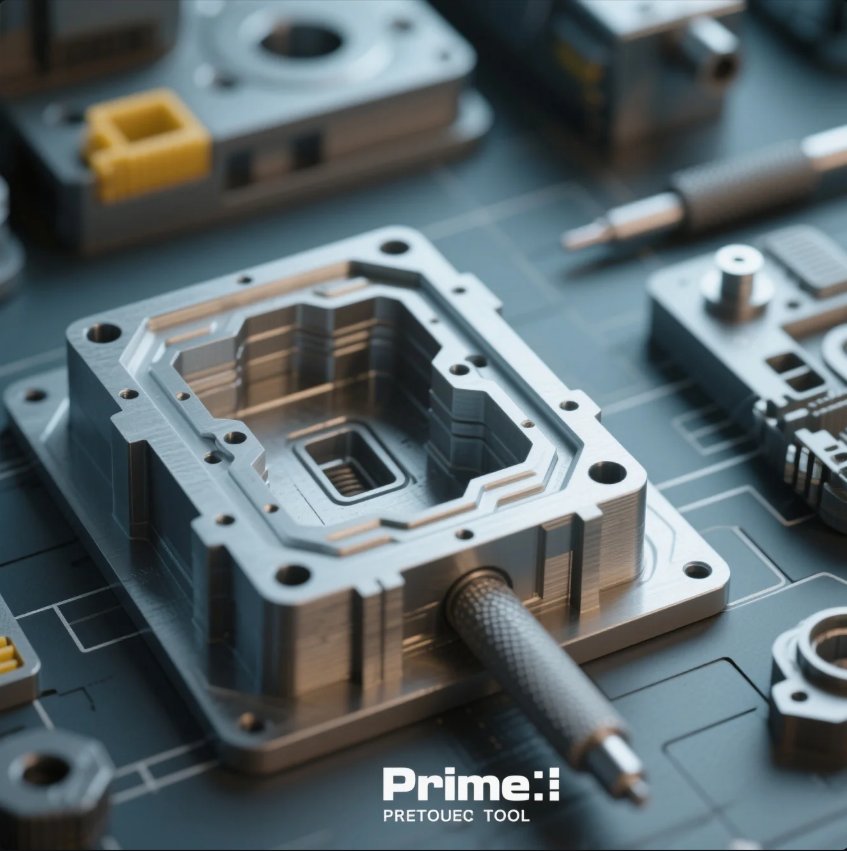

Image: 3D printed resin mold being tested in a low-pressure injection setup at Prime.

When It Works Best

| Use Case | Suitability |

|---|---|

| Prototypes | ✅ Excellent for testing fit/function |

| Short run (10–100 pcs) | ✅ Possible with proper resin |

| High volume | ❌ Not durable enough |

| High pressure/temperature | ❌ Most printed molds degrade quickly |

At Prime, we help clients validate their part designs early by using printed molds before investing in metal tooling. If you’re wondering "can you injection mold with a 3D printer?" for a small batch or functional model, the answer is likely yes—with the right setup.

Explore how Prime supports rapid prototyping →

What things are illegal to 3D print?

Even as you explore whether you can injection mold with a 3D printer, it’s important to stay compliant with international laws.

It’s illegal to 3D print weapons, counterfeit goods, and protected intellectual property without proper authorization.

Image: Sample product labeled for compliance, ensuring legal use of 3D printing files and designs.

What Not to Print

- Firearms and weapon components

- Government ID replicas or fake currencies

- Patented or copyrighted designs

- Unapproved medical implants

- Trademarks or logos without licensing

When working with Prime, we always develop original tooling designs under strict NDA agreements—ensuring that even your 3D-printed injection molds are fully legal and protected.

Learn more about IP protection in manufacturing →

Can PLA be used for injection molding?

Another variation of the question: can you injection mold with a 3D printer using PLA? Technically, yes. Practically, not really.

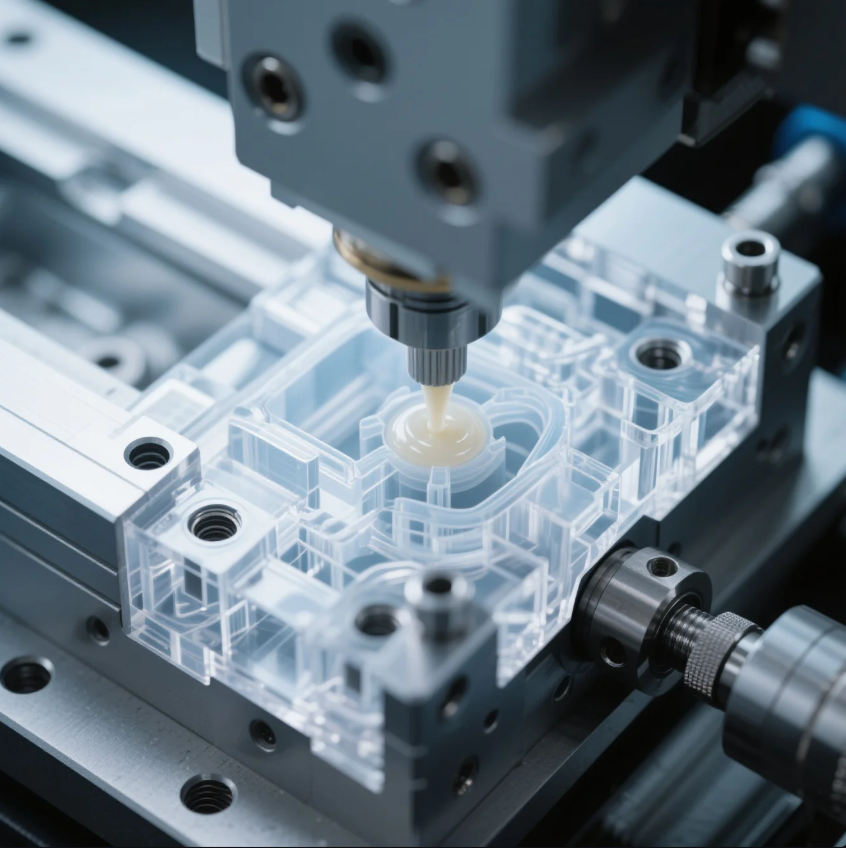

PLA deforms under heat and pressure, which makes it unreliable for molding. It may work for visual samples or casting, but not for actual injection molding.

Image: Warped PLA mold after limited use, showing lack of heat resistance under injection conditions.

Better Alternatives to PLA

| Material | Heat Tolerance | Mold Performance |

|---|---|---|

| PLA | 60–65°C | Poor (deforms quickly) |

| ABS | 90–100°C | Somewhat better |

| PETG | \~80°C | Still limited |

| Nylon/PC | 110–140°C | Acceptable for small runs |

| Steel/Aluminum | >500°C | Excellent for long-term use |

At Prime, we recommend SLA high-temperature resin for functional test molds and aluminum for long-term molding efficiency. If your part is complex, it’s essential to move beyond PLA early.

See our material durability comparison →

Which is cheaper, injection molding or 3D printing?

Can you injection mold with a 3D printer and save money? Only if your production volume is low.

3D printing is cost-effective for prototyping or very small quantities. Injection molding becomes cheaper and faster once production exceeds a few hundred units.

Image: Prime’s engineering chart showing break-even points between 3D printing and injection molding.

Price Comparison Overview

| Volume | 3D Printing | Injection Molding |

|---|---|---|

| 1–10 pcs | ✅ Cheaper option | ❌ High upfront tooling cost |

| 100–500 pcs | ✅ Still affordable | ❌ Tooling cost not justified |

| 1,000–10,000 pcs | ❌ Cost per part high | ✅ Lower unit cost |

| 100,000+ pcs | ❌ Not suitable | ✅ Ideal for large production |

If you’re still asking “can you injection mold with a 3D printer to save on cost,” remember that 3D printing only wins at low volumes. At Prime, we help clients plan production strategy based on both technical feasibility and total cost of ownership.

Request a free quote from Prime →

Conclusion

Can you injection mold with a 3D printer? Absolutely—for early development and limited runs. But traditional molds still lead in long-term quality, durability, and cost-effectiveness.

Looking to compare printed molds vs traditional steel tooling for your product?

Contact Prime today at https://primecustomparts.com or https://primecustomparts.com for expert advice, DFM review, or sample testing. Whether you’re prototyping or scaling globally, we support you at every stage of product development.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com