Custom Metal Forgings: What Types Benefit Machinery and Energy Fields Most?

Custom Metal Forgings: What Types Benefit Machinery and Energy Fields Most? Weak or incorrectly forged metal components often lead to equipment failure1 and expensive downtime. Without clarity on metal forging options2, selecting the right parts becomes challenging, putting your productivity at risk. Custom metal forgings produce robust, durable components tailored for machinery and energy fields. […]

How Custom Metal Forgings Improve Strength & Precision in Aerospace & Automotive Parts?

How Custom Metal Forgings Improve Strength & Precision in Aerospace & Automotive Parts? Faulty metal components often result in operational failures1, costly downtime, and compromised safety. Custom metal forgings effectively eliminate these risks by delivering enhanced strength, precision, and reliability. Custom metal forgings significantly enhance strength, durability, and precision, making them ideal for aerospace and […]

Why Do Industrial Buyers Prefer Custom Metal Forgings for Precision Components?

Why Do Industrial Buyers Prefer Custom Metal Forgings for Precision Components? Industrial buyers often face unstable quality, missed deadlines, and lack of customization1 when sourcing metal parts2 for demanding industrial projects. Custom metal forgings deliver unmatched precision, mechanical strength, and design flexibility for industrial buyers worldwide. These solutions meet the most rigorous requirements of automotive, […]

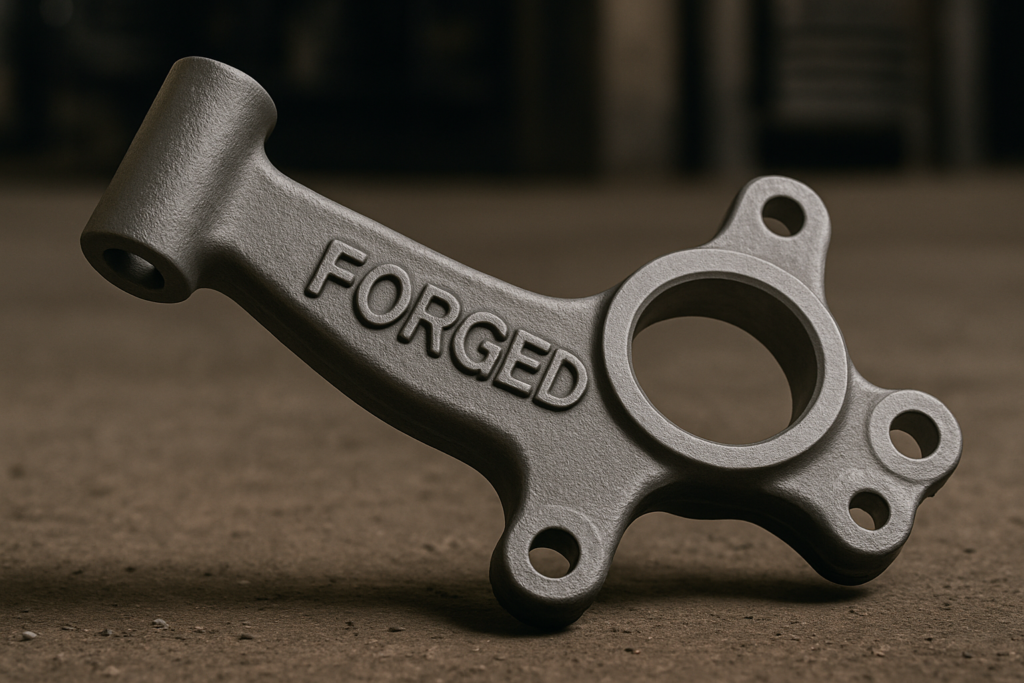

Free vs. Closed-Die Forging: Best Method for Heavy Machinery?

Free vs. Closed-Die Forging: Best Method for Heavy Machinery? When choosing between free forging1 and closed-die forging2 for heavy machinery, precision, efficiency, and cost play crucial roles. This article will explore the fundamental processes and applications of both methods, their advantages, and cost analysis to help you decide which is best for your needs. Free […]

How Die Forging Powers Aerospace & Automotive Manufacturing?

How Die Forging Powers Aerospace & Automotive Manufacturing? Die forging is a manufacturing technique that shapes metal into precise parts using high-pressure equipment1. Imagine you have a metal piece and a mold; a big press applies force to shape the metal exactly as needed. This method ensures strength2 and uniformity, making it essential in aerospace […]

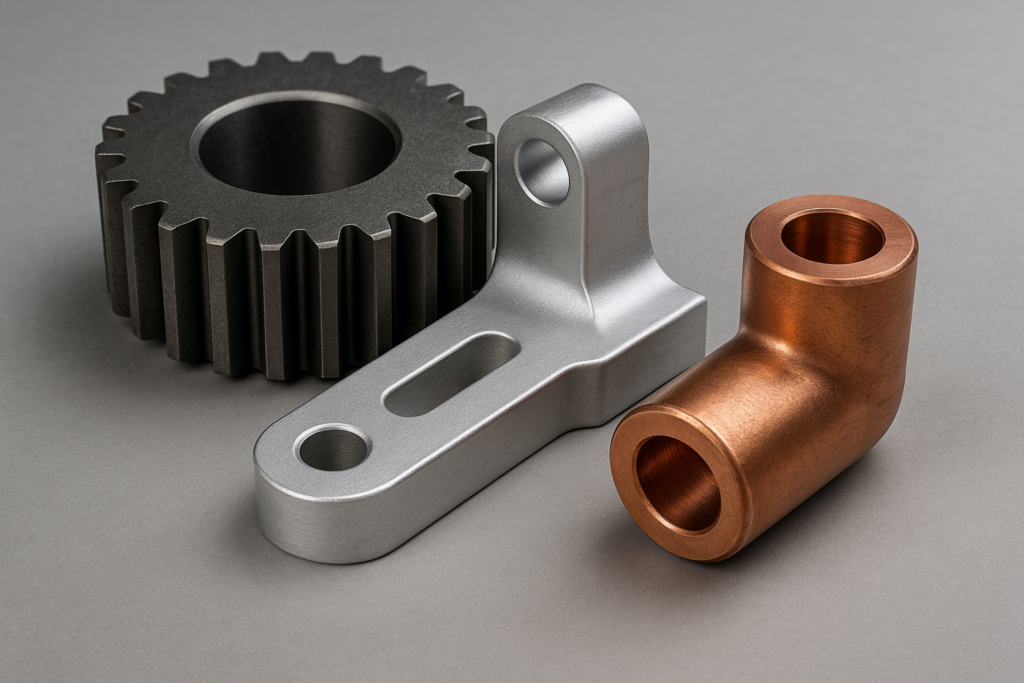

The Ultimate Guide to Metal Forging: Types, Applications & Benefits

The Ultimate Guide to Metal Forging: Types, Applications & Benefits Metal forging is a versatile manufacturing process that shapes metal under high pressure, enhancing its mechanical properties. This guide will explore different forging techniques1, the importance of precision forging2, the right material choices, and the benefits of professional forging services. Metal forging produces components with […]

Custom Metal Forgings: What Are the Essential Design Considerations, Surface Treatments, and Lessons from Real-World Projects?

Custom Metal Forgings: What Are the Essential Design Considerations, Surface Treatments, and Lessons from Real-World Projects? Custom metal forgings have become essential across aerospace, automotive, oil & gas, and heavy industry, especially when off-the-shelf parts fail to meet technical, quality, or cost targets. Choosing the right design, surface treatment, and supplier is crucial. Every year, […]

How to Source High-Quality Metal Forging Parts from China: What Should Buyers Focus on for Supplier Selection and Quality Control?

How to Source High-Quality Metal Forging Parts from China: What Should Buyers Focus on for Supplier Selection and Quality Control? Sourcing metal forging parts from China offers global buyers major cost and speed advantages, but only when supplier selection and quality control are taken seriously from day one. I have worked with dozens of international […]

The Definitive Guide to Metal Forgings: What Types, Benefits, and Applications Should You Know?

The Definitive Guide to Metal Forgings: What Types, Benefits, and Applications Should You Know? Metal forging stands at the core of modern manufacturing, yet many buyers remain confused about forging types and supplier options. Metal forging uses controlled pressure to shape metal into high-strength forms. This process delivers outstanding toughness and reliability compared to casting […]

2025 Trends in Metal Forging: Technology, Materials, and Sustainability

2025 Trends in Metal Forging: Technology, Materials, and Sustainability Supply chains in 2025 demand more than durability. Customers want smarter, cleaner, and lighter forged parts. As buyers shift to online channels, and regulations tighten, forging manufacturers must evolve. At Prime, we see four key trends shaping the future: smart automation, green production, next-gen alloys, and […]