How do you use a metal banding tool?

How do you use a metal banding tool? Securing heavy loads with loose or uneven straps can lead to shipping damage—or serious injury. To use a metal banding tool, wrap the band around your item, feed it into the tensioner, tighten, apply a seal, and crimp it in place using a sealer or band-it tool. […]

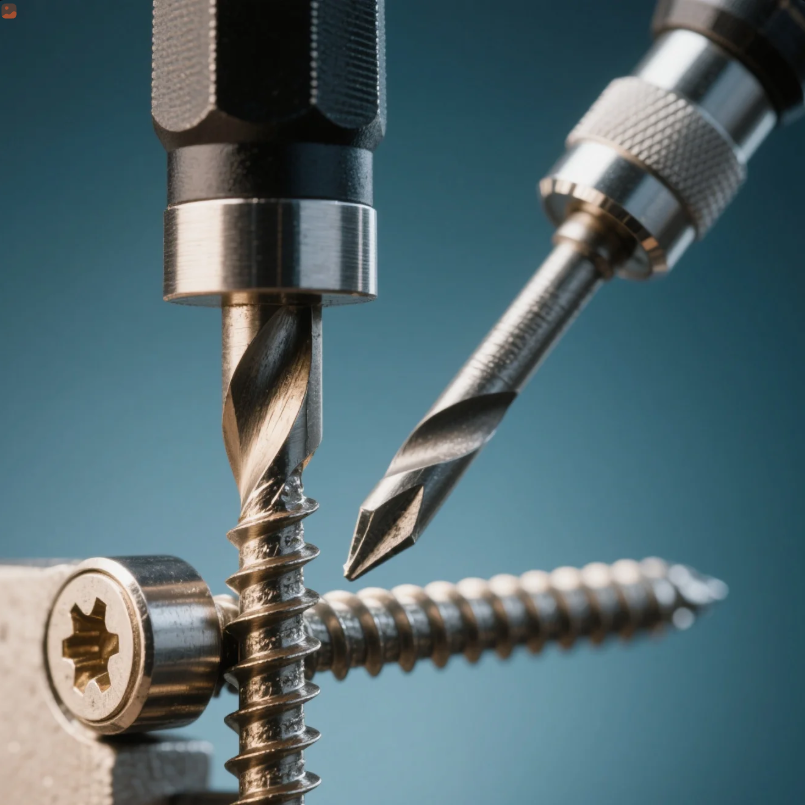

How do you use a metal screw extractor?

How do you use a metal screw extractor? Stripped or broken screws in metal parts can halt your whole assembly process. To use a metal screw extractor, drill a guide hole into the damaged screw, insert the extractor, and turn it counterclockwise to remove the screw. At Prime, we use screw extractors during metal assembly […]

How do you use a metal nibbler?

How do you use a metal nibbler? Cutting curves or tight corners in sheet metal? A nibbler might be your best tool. To use a metal nibbler, guide the cutting head along the marked line while applying steady forward pressure. The tool punches small bits out of the metal, allowing for precise and clean cuts. […]

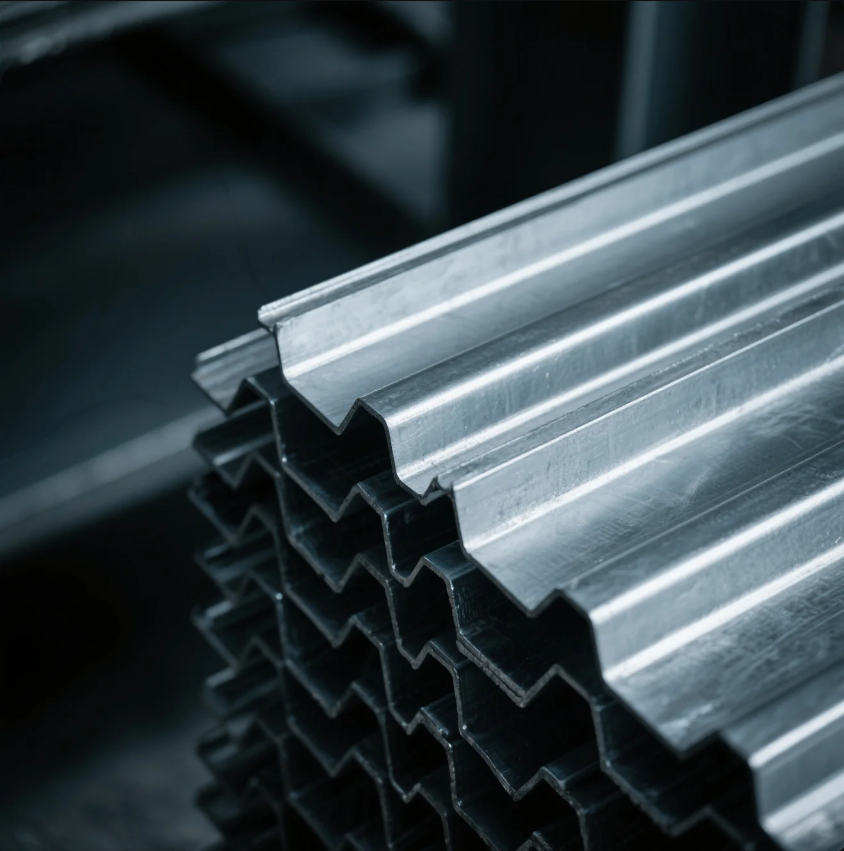

What is the burring process in sheet metal?

What Is the Burring Process in Sheet Metal? Most buyers in the sheet metal industry face recurring issues with sharp edges, burrs, and incomplete finishes. These quality gaps often result in safety risks, increased returns, and extra labor costs. Understanding the burring process and working with reliable ISO-certified suppliers like Prime is essential for global […]

How do you cut sheet metal smooth?

How do you cut sheet metal smooth? Cutting sheet metal often leaves jagged edges that are unsafe and hard to finish. To cut sheet metal smoothly, use sharp tools like aviation snips, jigsaws with metal blades, or laser cutters. Follow up with edge finishing tools for a clean result. At Prime, we use CNC and […]

How do you use a sheet metal deburring tool?

How do you use a sheet metal deburring tool? Rough edges on sheet metal are more than cosmetic—they create safety hazards and interfere with assembly. To use a sheet metal deburring tool, glide the blade along the edge or inside holes at a 45° angle to remove burrs. Apply light, steady pressure. At Prime, we […]

What is the easiest way to cut metal by hand?

What is the easiest way to cut metal by hand? Cutting metal by hand can feel tough—unless you have the right tool for the job. The easiest way to cut metal by hand is with aviation snips, a hacksaw, or a rotary tool, depending on material thickness and shape. At Prime, we advise clients on […]

What is the best tool for smoothing edges on a piece of metal?

What is the best tool for smoothing edges on a piece of metal? Rough metal edges aren’t just ugly—they can be dangerous or lead to product failure. The best tool for smoothing metal edges depends on your part size and finish need. Common tools include flap wheels, belt grinders, deburring blades, and files. At Prime, […]

How do you dull the edge of sheet metal?

How do you dull the edge of sheet metal? Sharp edges on sheet metal aren’t just unsafe—they can ruin your entire assembly. To dull the edge of sheet metal, use sanding, filing, edge rounding, or hemming to soften sharp cuts and create smooth, safe profiles. At Prime, we apply this finishing step on all cut, […]

How to deburr metal by hand?

How to deburr metal by hand? Sharp burrs on metal edges can injure workers and ruin assemblies. To deburr metal by hand, use tools like flat files, deburring blades, sandpaper, or abrasive blocks to remove sharp edges and smooth the surface. At Prime, we deburr manually for low-volume or high-detail parts, ensuring every custom metal […]