Top Material Selection Strategies to Reduce Costs in Custom Metal Stamping Parts?

Top Material Selection Strategies to Reduce Costs in Custom Metal Stamping Parts? I lose money when parts are overbuilt. You do too. The fix starts with material choices that match real loads, not wishful thinking. Pick the lowest-cost metal grade that still meets strength, formability, corrosion, and electrical needs. Verify with simple tests and standards. […]

How can I cut total cost for precision stamped metal parts?

How can I cut total cost for precision stamped metal parts? Margins feel tight. Lead times slip. Quality noise grows. I give clear, low-risk steps now. You can cut stamping cost1 by fixing design waste, choosing the right die path, stabilizing materials, and standardizing packaging. Then you protect launches with SPC, smart logistics, and clean […]

Cost-Effectiveness in Metal Stamping: Tips and Strategies

Cost-Effectiveness in Metal Stamping: Tips and Strategies? Costs rise and launches slip. I understand the pressure. I share clear stamping strategies that cut spend fast without new risk. Metal stamping becomes cost-effective1 when design, process, and supply choices align. Match geometry and volume to the right die path. Add in-die features and smart packaging to […]

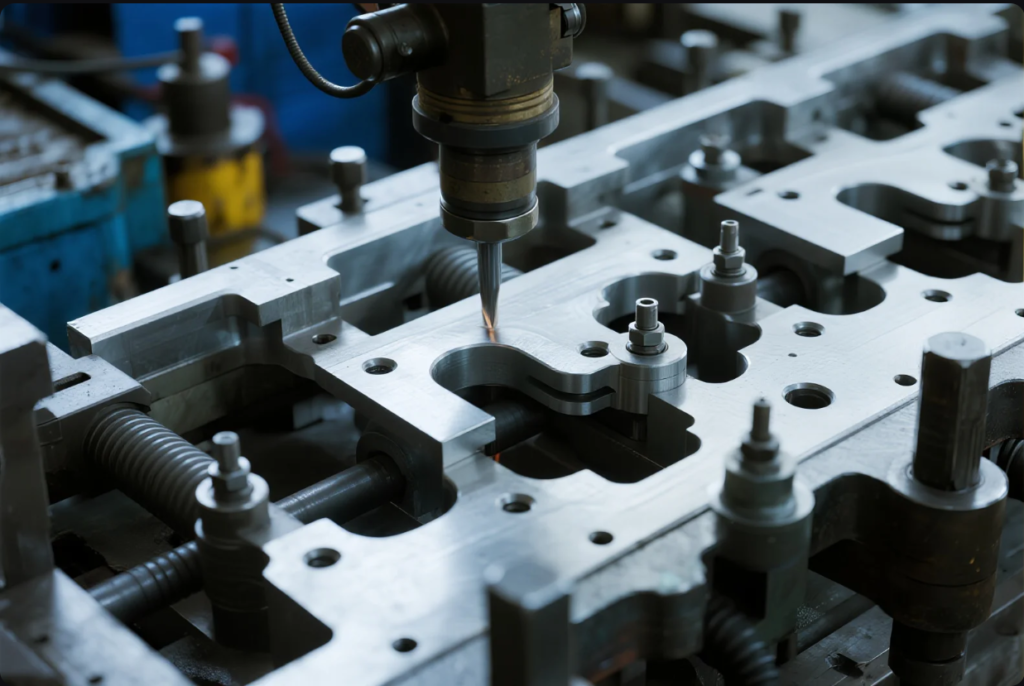

Cost-Effective Types of Metal Stamping Techniques

Which metal stamping techniques cut total cost the most? You face rising costs1 and tight launches. Delays hit profit, and waste grows fast. I share clear, low-risk stamping choices2. Metal stamping cost falls when tooling matches volume, geometry, and tolerance. Teams compare progressive, compound, transfer, fourslide, and short-run routes1. Each route shifts die cost, press […]

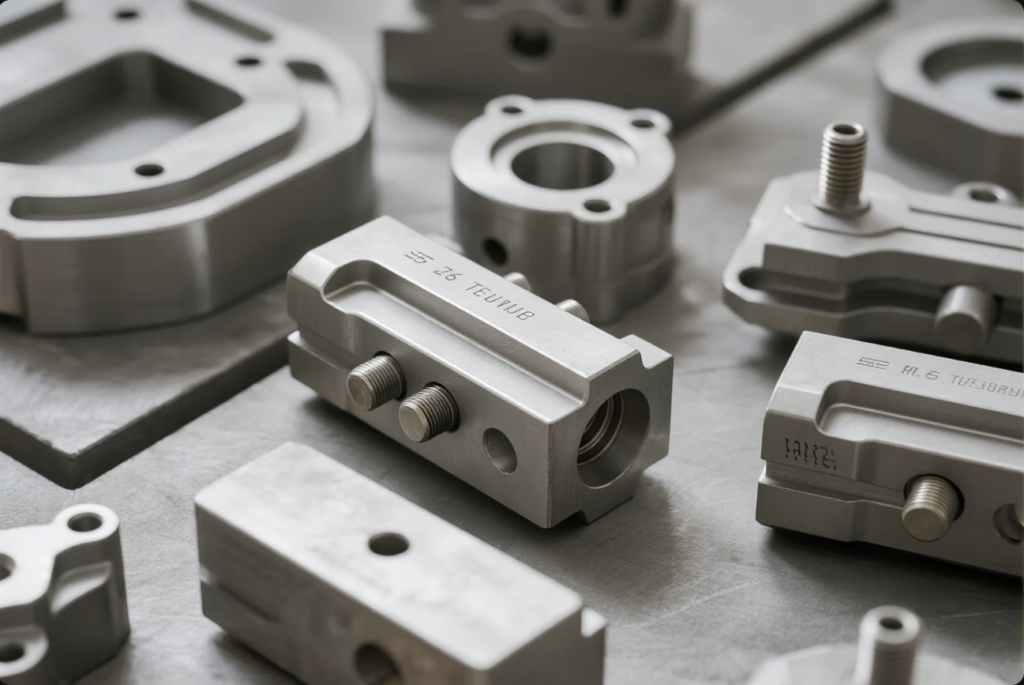

Custom Metal Stamping Parts: How to Choose, Design & Ensure Quality?

Custom Metal Stamping Parts: How to Choose, Design & Ensure Quality? Struggling with inconsistent quality in custom metal stampings1? Choosing the right metal stamping process2 and supplier ensures reliable performance, fast delivery, and long-term cost savings. Learn what matters. Many engineers and buyers face delays, poor tolerances, or unclear feedback. With the right approach, you […]

What Are the Best Practices for Designing Custom Metal Stamping and Deep Drawn Components?

What Are the Best Practices for Designing Custom Metal Stamping and Deep Drawn Components? Sourcing high-quality custom stamped and deep drawn parts is a challenge for every engineer or buyer, whether you’re supporting automotive, aerospace, electronics, or emerging energy applications. Poor design, overlooked secondary processes, and supplier miscommunication drive up costs and result in late […]

How to Source Custom Precision Stamping Parts from China: Cost, Quality, and Supplier Selection Explained?

How to Source Custom Precision Stamping Parts from China: Cost, Quality, and Supplier Selection Explained? Many international buyers want to source custom stamping parts from China, but often face challenges with verifying supplier capabilities, controlling cost, and managing quality risks. To succeed in global sourcing, you need more than price—you need a trusted partner with […]

Precision Metal Stamping Parts: How to Choose the Right Material, Process, and Supplier?

Precision Metal Stamping Parts: How to Choose the Right Material, Process, and Supplier? When sourcing precision metal stamping parts, many buyers feel unsure about materials, tolerances, and quality control. Precision metal stamping parts are key in many industries. Selecting the right materials, process, and supplier ensures durability, fit, and reliability. This guide explains core definitions, […]

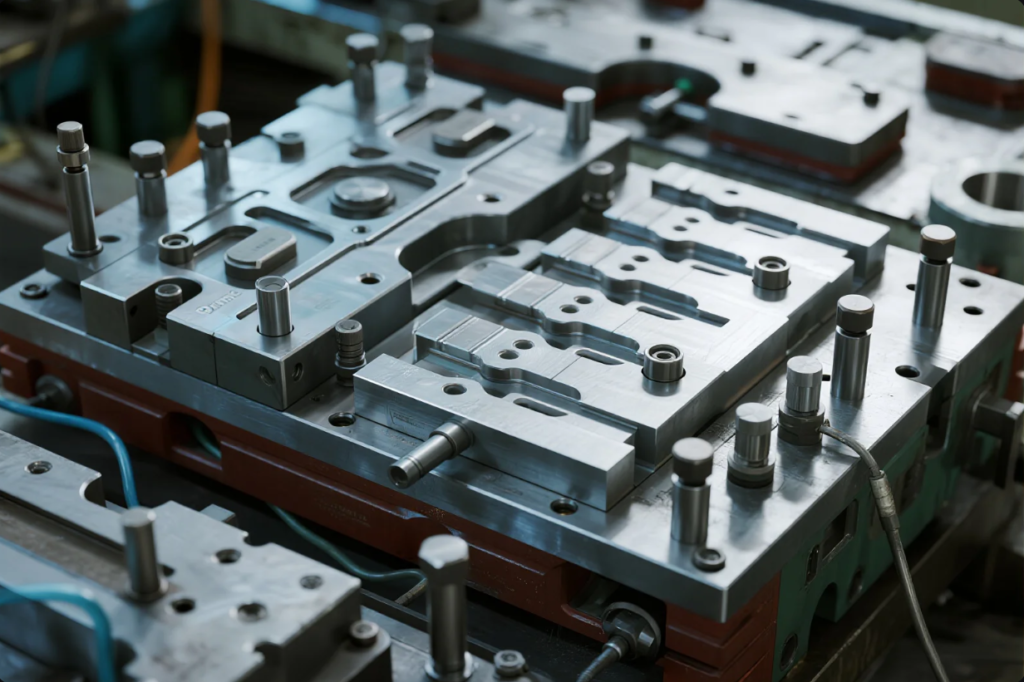

Standardization in Metal Stamping Dies: Why It Matters

Standardization in Metal Stamping Dies: Why It Matters Modular die components: Benefits for tooling consistency Standard modules such as punch blocks, stripper plates, and guide pillars simplify sourcing and reduce lead time. Industries like automotive and consumer electronics rely on systems from Meusburger and MISUMI to ensure consistent fit and performance. Key Benefits: Faster repairs […]

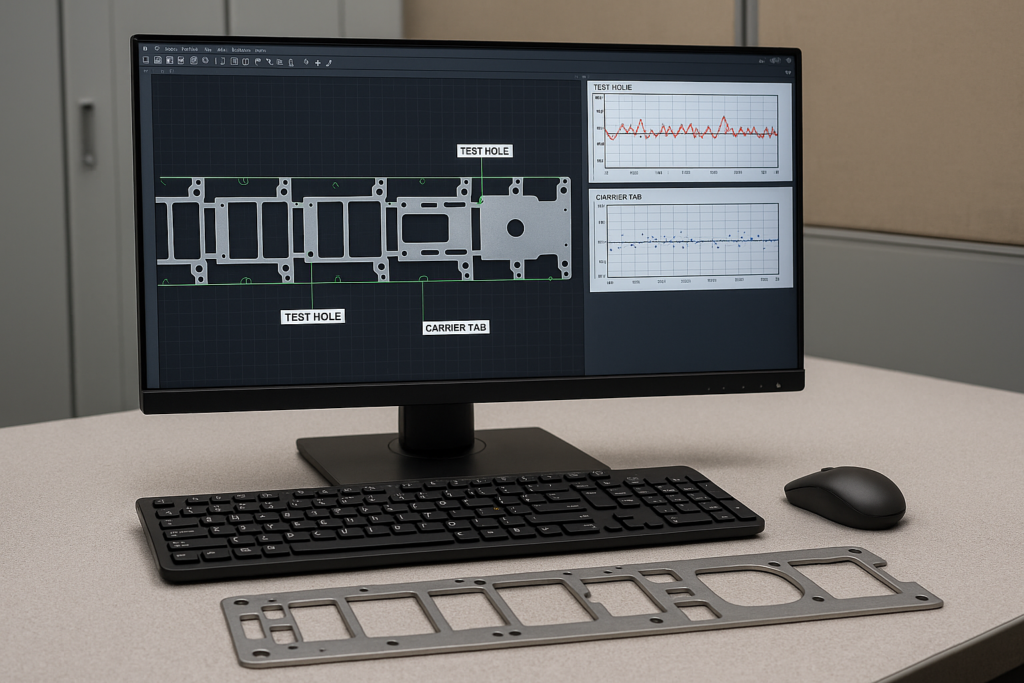

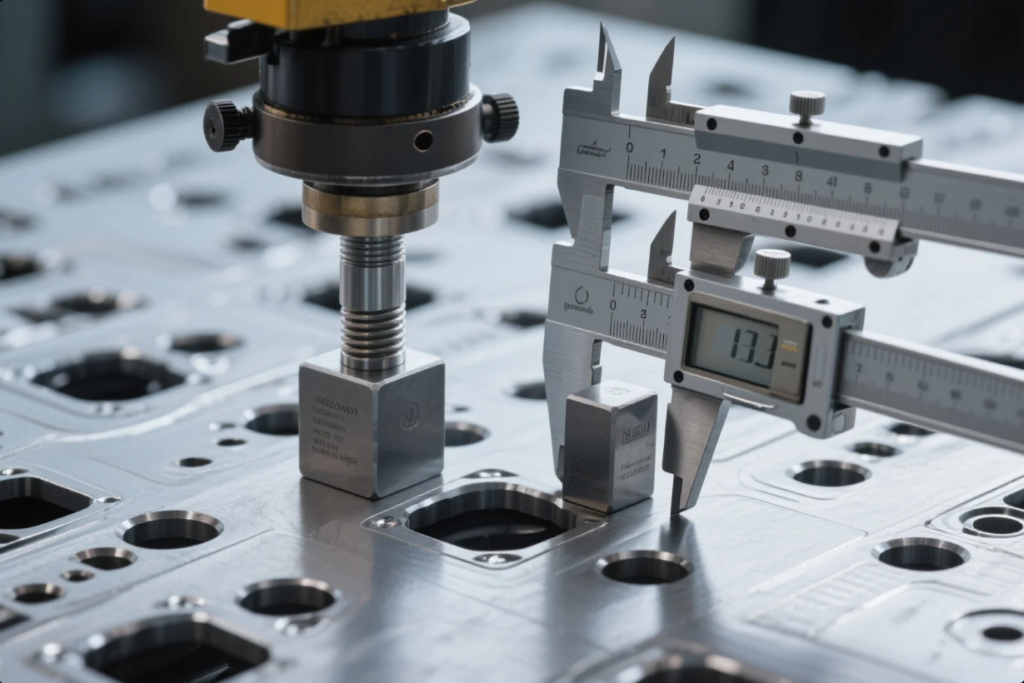

Stamping Die Maintenance: Ensuring Precision in Every Part

Stamping Die Maintenance: Ensuring Precision in Every Part How stamping tolerance affects die accuracy Stamping to a tolerance of ±0.02 mm is essential for ISO 2768 and automotive standards such as IATF 16949. Small deviations from die wear or press misalignment can cause part rejection, assembly issues, and increased scrap costs, as documented by MetalForming Magazine […]