What is stamping metal called?

What is stamping metal called? Stamping metal is more than just pressing—it’s a precise industrial process with many applications. Stamping metal is called metal stamping or press working. It forms metal sheets into parts using dies and presses. In this article, I’ll break down the terminology, processes, tools, and materials used in stamping—plus how Prime […]

What are the four types of metal stamping?

What are the four types of metal stamping? Metal stamping is not one-size-fits-all. Different jobs need different stamping methods. The four main types of metal stamping are progressive die stamping, transfer die stamping, four-slide stamping, and deep draw stamping. Each serves different functions. Choosing the wrong method can waste material and raise costs. In this […]

Can you stamp metal at home?

Can you stamp metal at home? Yes, you can stamp metal at home. But results vary based on tools, materials, and technique. Home metal stamping is possible for soft metals and simple shapes. It requires basic tools, steady hands, and patience. In this article, I’ll explain how home stamping differs from industrial stamping and when […]

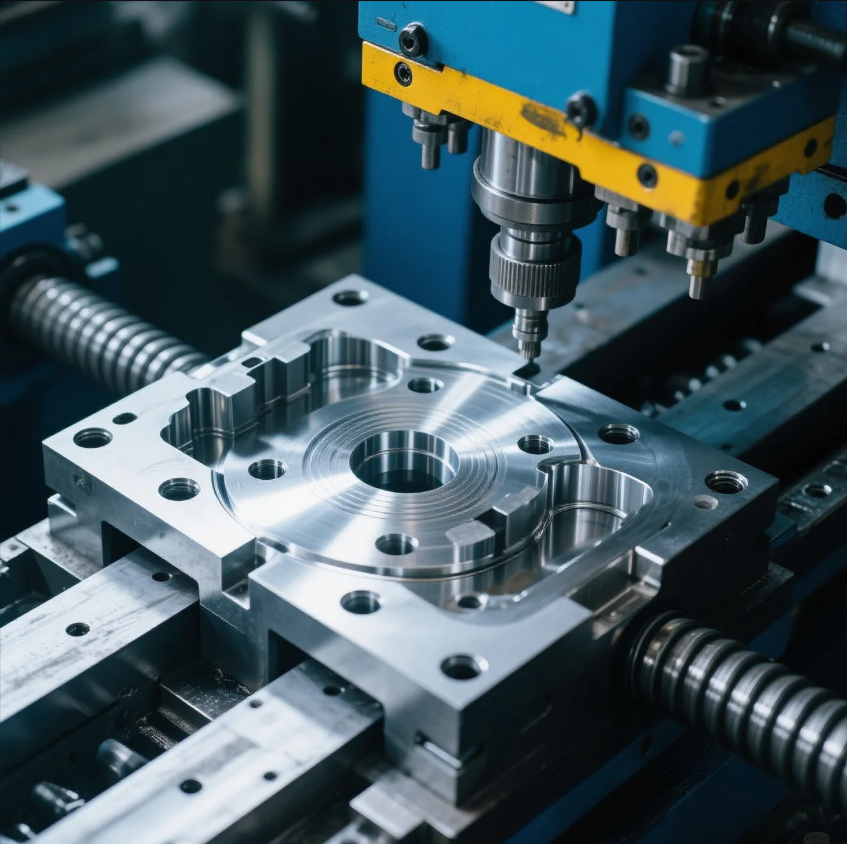

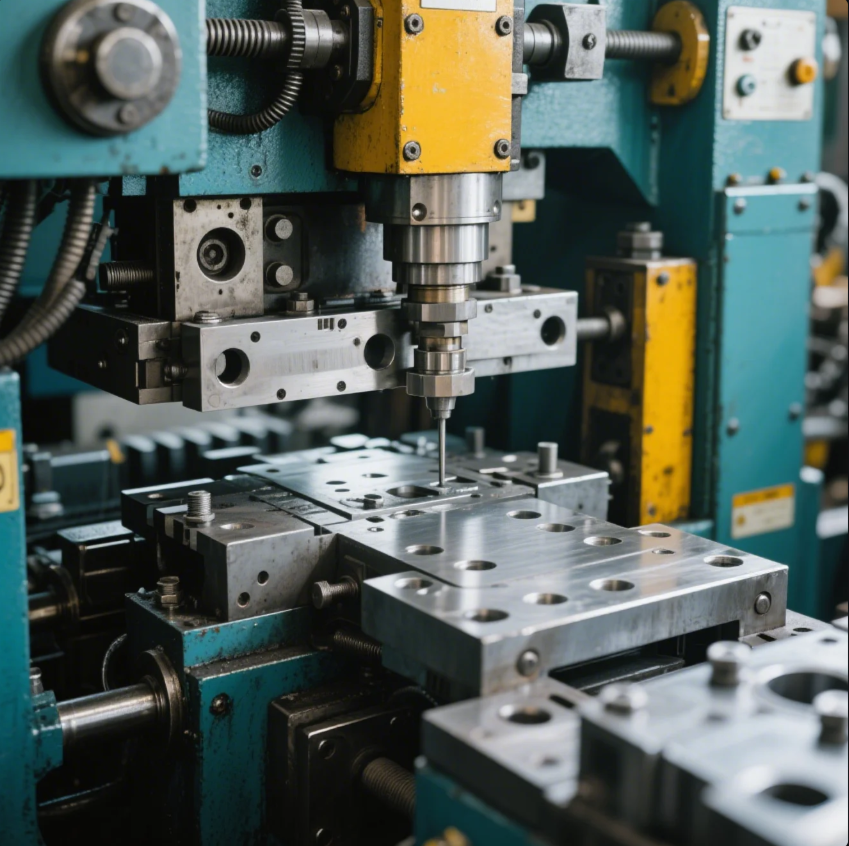

What is a metal stamping machine?

What is a metal stamping machine? Stamping machines shape metal fast and precisely. They’re essential for high-volume industrial parts. A metal stamping machine presses sheet metal into shapes using a die. It’s widely used in mining, automotive, and machinery parts production. Using the right stamping method saves time, cost, and boosts part consistency. In this […]

What is the process of forming and stamping?

What is the process of forming and stamping? Raw metal sheets need force and accuracy to become usable parts. Forming and stamping are industrial processes that shape flat metal sheets into precise components using mechanical or hydraulic presses and custom dies. These methods are fast, repeatable, and ideal for high-volume manufacturing. What is the process […]

What are the steps in stamping?

What are the steps in stamping? Stamping turns raw metal into functional parts—but only if the process is precise. The stamping process involves a sequence of operations such as blanking, piercing, bending, forming, drawing, trimming, and coining. Each step shapes the sheet metal progressively until the final part is ready. What are the steps in […]

How does a stamping machine work?

How does a stamping machine work? Metal parts don’t shape themselves—precision stamping machines do the heavy work. A stamping machine works by applying controlled force through a die to cut, bend, or shape metal sheets into desired forms. The process uses mechanical or hydraulic power, depending on the application and part complexity. How do stamping […]

What machine is used for stamping?

What machine is used for stamping? Metal stamping requires high precision, force, and speed to shape components effectively. Stamping is typically done using a press machine—most commonly a mechanical press or hydraulic press, depending on material and complexity. Each machine type serves different applications in automotive, electronics, and industrial manufacturing. What is a stamping machine […]

What is the advantage of stamp?

What is the advantage of stamp and why is it valuable in both business and production? From factory parts to official documents, stamps play a bigger role than most realize. Stamps offer fast validation, identity marking, and high-speed manufacturing accuracy—all critical in modern workflows. Let’s explore how stamps add value across industries. LOOP_START What are […]

What is the effect of stamping?

What is the effect of stamping and how does it improve manufacturing outcomes? Manufacturers constantly seek faster, cheaper, and more reliable ways to produce metal components. Stamping improves production speed, consistency, and cost-efficiency by transforming sheet metal into precise parts at scale. Let’s explore the full impact of stamping on modern manufacturing and product performance. […]