What is stamped used for?

What Are Stamped Parts Used For? The Hidden World of Pressed Metal Modern manufacturers deploy stamped metal parts in 93% of durable goods – our Prime facility alone produces over 500 distinct components daily, from micro-battery contacts to truck chassis beams, demonstrating stamping’s unmatched versatility across industries. Snippet paragraph: Stamped parts serve critical functions in […]

What do you mean by stamped?

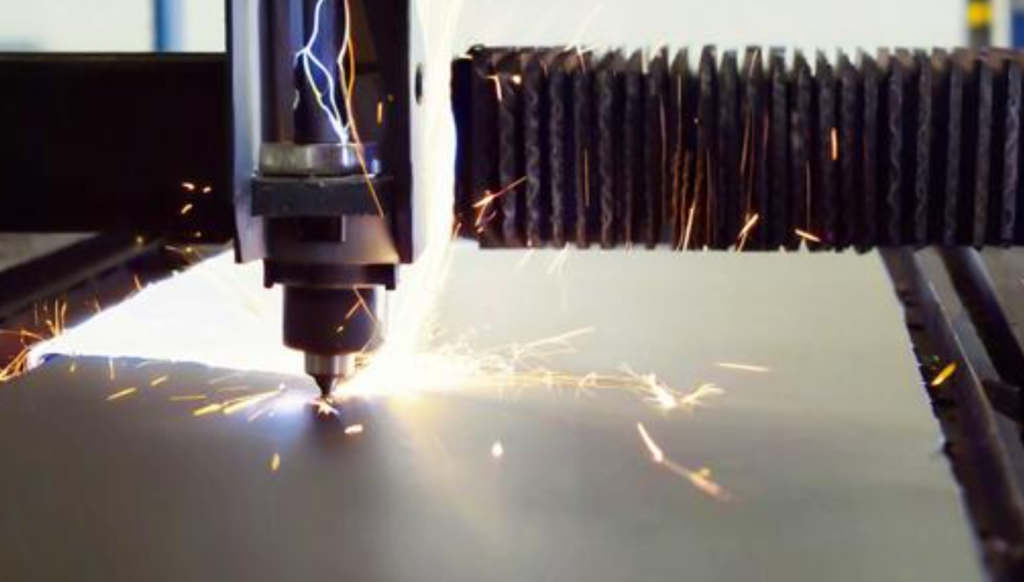

What Does "Stamped" Mean? The Science Behind Metal Stamping When manufacturers say a part is "stamped," they mean it was shaped using 8-20 tons of force per square inch to transform flat metal stock into precise components – our Prime facility stamps over 15 million parts monthly with tolerances as tight as human hair (0.05mm). […]

What equipment is used for stamping?

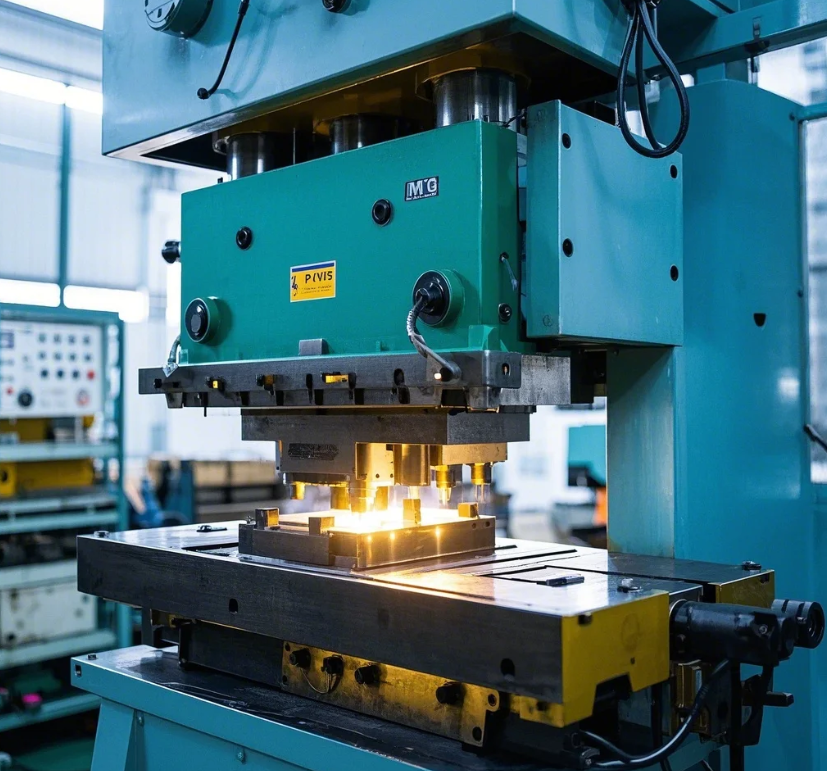

What Equipment is Used for Stamping? The Complete Machinery Guide Modern stamping facilities deploy 15+ specialized machines working in tandem to transform coils of metal into precision parts at rates exceeding 1,500 strokes per minute – our Prime facility alone operates 62 presses ranging from 5 to 2,500 tons. Snippet paragraph: Core stamping equipment includes […]

Why is stamping used?

Why is Stamping Used? The Manufacturing Advantages of Metal Stamping Stamping dominates metal forming because it achieves 95% material utilization at rates exceeding 1,500 parts per minute – 70% faster than CNC machining and 90% cheaper than 3D printing for mass production. Snippet paragraph: Metal stamping creates net-shape parts with tolerances to ±0.025mm at unit […]

What is a stamping tool?

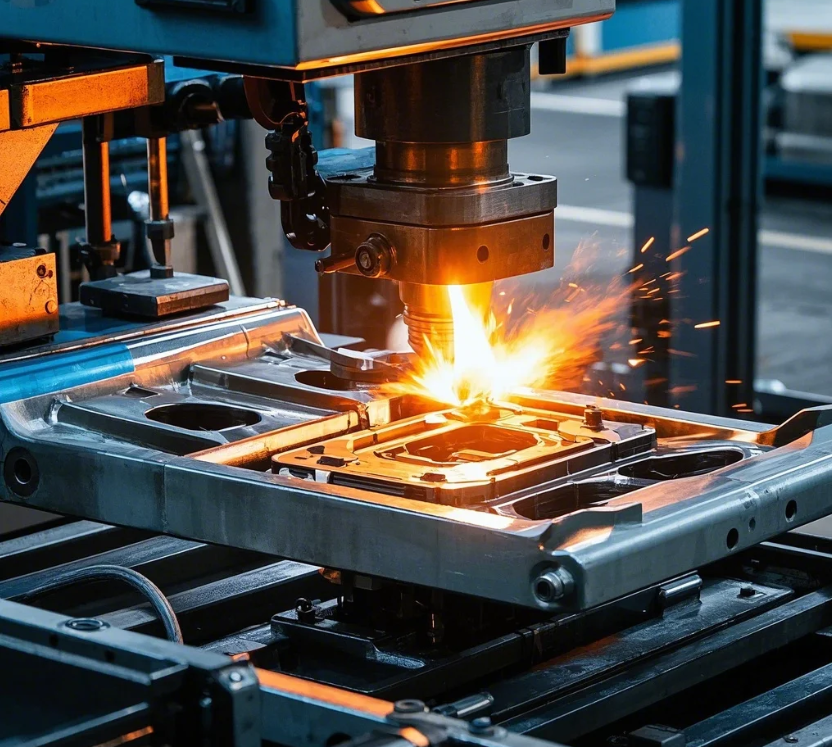

What is a Stamping Tool? The Essential Guide to Metal Forming Instruments Stamping tools transform flat metal into complex 3D shapes at production speeds exceeding 1,200 parts per minute. These specialized tools account for 70% of total stamping system costs but enable per-part costs under $0.01 in high-volume runs. Snippet paragraph: A stamping tool (also […]

How to stamp metal parts?

How to Stamp Metal Parts? The Complete Guide for Precision Fabrication Metal stamping transforms flat stock into complex shapes with up to ±0.025mm accuracy at 300+ strokes per minute. Poor setup causes 70% of dimensional defects in formed parts. Snippet paragraph: To stamp metal, first choose a press (mechanical for speed, hydraulic for force), design […]

What are the 94 types of metals?

What Are the 94 Types of Metals and Why Are They Important? A periodic table showing the 94 metal elements used in modern industries. From smartphones and satellites to structural beams and surgical tools, metals are everywhere. But how many types of metal are there? The answer lies in one essential question: what are the […]

What is the difference between embossing and stamping metal?

What Is the Difference Between Embossing and Stamping Metal? Embossing and stamping are both metalworking techniques, but they serve different purposes and achieve distinct results. Snippet paragraph: Embossing raises a design on metal surfaces, creating a 3D effect, while stamping involves cutting or shaping metal using dies. Understanding these differences is crucial for selecting the […]

What are the four types of metal stamping?

What Are the Four Types of Metal Stamping? Metal stamping is a vital manufacturing process that shapes metal sheets into desired forms. Understanding the four primary types of metal stamping—progressive die stamping, transfer die stamping, compound stamping, and four-slide stamping—is essential for selecting the appropriate method for specific applications. Snippet paragraph: The four main types […]

What Do You Mean by Stamping?

What Does Stamping Really Mean? Prime Custom Parts factory: high-speed metal forming underway. "Stamping" is a versatile word. In some contexts, it suggests identity or authority; in others, it refers to a highly technical manufacturing method used to shape metal parts with precision and speed. This guide breaks down its meanings—from figurative language to practical […]