Custom CNC Metal Parts Manufacturing: What Should OEM Buyers Know About Design, Materials, and Surface Finishes?

OEM buyers must navigate a complex landscape—balancing technical requirements, pricing, global logistics, and strict quality standards. Whether you represent medical devices, aerospace engineering, energy systems, or industrial automation, understanding every detail of CNC metal part sourcing is crucial. Over the years, I’ve managed projects with top US manufacturers, European OEMs, and fast-growing Asian brands, learning first-hand what drives results—and what risks to avoid.

This guide links you to more than 100 authoritative global resources, live standards, and real supplier platforms. With images, real-world cases, and advanced tips, you’ll build the skills and network to thrive in custom CNC sourcing.

Choosing the Right Materials for CNC Machined Metal Components?

Material choice is foundational for every project. Global CNC buyers must understand not only mechanical properties but also cost, lead time, export regulations, and compliance.

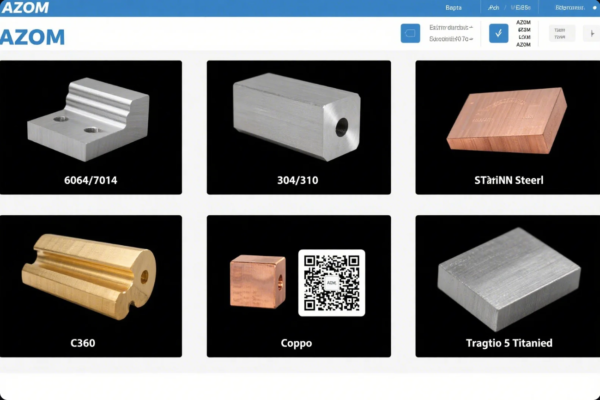

The best start is to research at Matmatch, AZOM, MakeItFrom.com, Engineering Toolbox, and MetalMiner.

Common CNC Metals and Why They Matter

- Aluminum (6061/7075): High machinability, moderate strength, low weight. Used in drones, consumer electronics, automotive brackets, bicycle parts.

- 304/316 Stainless Steel: Excellent corrosion resistance, hygiene. Key for food, medical, marine.

- Brass (C360) and Copper: Top choice for electrical connectors, thermal management, plumbing.

- Titanium (grade 5): Superior strength-to-weight, corrosion proof. Aerospace, motorsport, implants.

For real-time cost and sourcing, check OnlineMetals, Ryerson, Metal Supermarkets, Baosteel, and Thyssenkrupp. For certifications, use SGS, TÜV Rheinland, and Bureau Veritas.

How to Specify Materials Effectively

- Always include international standards (ASTM, SAE, EN, JIS) in your RFQ.

- Request mill certificates, batch traceability, and cross-check with Panjiva or ImportYeti to validate your supplier’s history.

- For regulated industries, confirm RoHS (EU RoHS), REACH (ECHA), and regional standards (FDA, ISO 13485, AS9100).

Sourcing for Industry Needs: Sector-Specific Material and Compliance Tips

Not every industry or region has the same needs! For example, food industry buyers often demand 316L stainless with full passivation and FDA compliance.

Automotive and motorsport require materials with traceable mechanical properties and IATF/ISO certification.

Medical demands ISO 13485, biocompatibility (Titanium Grade 2/5), and sometimes UDI barcode marking (GS1).

Aerospace sourcing involves AS9100 and detailed FMEA documentation.

Global buyers should partner with suppliers who understand these compliance requirements and can show verifiable certificates from SGS, Bureau Veritas, or Intertek.

Design for Manufacturability: Reducing Cost and Lead Time in CNC Machining?

A great design means nothing if it cannot be manufactured efficiently.

I recommend all buyers utilize Xometry’s DFM guidelines, Hubs CNC Design Guide, and Protolabs’ DFM tools.

For deep training, check MIT’s open DFM lectures and SME principles.

Best practices include:

- Using standardized holes and thread sizes

- Designing with uniform wall thickness and generous radii (Hubs guide)

- Limiting tight tolerances only to mission-critical surfaces (Protolabs Tolerances)

- Avoiding deep pockets and sharp internal corners, unless functionally required

Secure file exchange and live reviews are easy via Dropbox, Google Drive, Slack, or Microsoft Teams.

For automated quotes and DFM:

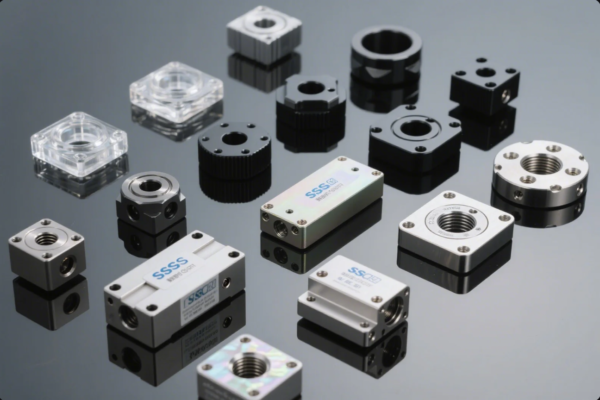

How to Achieve Complex Geometries and Precision

When clients ask for difficult geometries—undercuts, thin walls, or micro features—success depends on the supplier’s capabilities and software.

Top shops use 5-axis CNC with CAM software like Mastercam, HyperMill, or SolidCAM.

For micron-level tolerance, verify with Zeiss CMM, Keyence measurement systems, and use suppliers with in-house calibration (ISO 17025).

Prototype quickly: Leverage Hubs Rapid Prototyping, Protolabs Quick-Turn CNC, or Fictiv for same-week delivery.

Popular Surface Finishes for CNC Metal Parts: Anodizing, Powder Coating, and More?

Finishing options affect corrosion resistance, wear, branding, and regulatory acceptance.

Aluminum parts often get anodizing for color and protection (consumer products, optics, aerospace), while powder coating is chosen for heavy-duty, outdoor, or high-visibility parts. Electroplating (nickel/chrome) adds wear, electrical, or decorative value.

Key references:

For compliance, confirm RoHS and REACH status before order approval.

Advanced Finishing Options and Branding

Branding and function can go hand-in-hand. I’ve helped brands differentiate with laser engraving for traceability, color-coded anodizing for assembly, and multi-step finishes for luxury or consumer markets.

Automotive, bicycle, and sports equipment makers use contrasting finishes, logos, and QR/barcodes to fight counterfeits and boost market trust.

Inspection, Quality Standards, and Global Logistics

World-class supply means rigorous, documented QC and transparent delivery.

Start with supplier ISO 9001, IATF 16949, AS9100, or ISO 13485 certificates.

Third-party inspection is available with QIMA, Asia Quality Focus, Intertek, or Bureau Veritas.

Inspection process:

- In-process QC, using Keyence digital gauges, Mitutoyo micrometers, and Zeiss CMM

- Final shipment QC with digital reports uploaded to SAP, Oracle NetSuite, or Zoho Inventory

- Pre-shipment images and live tracking via DHL, FedEx, UPS, Maersk

Documentation:

Prepare COO, MSDS, and HS code.

For legal, Nolo NDA Templates and China IPR Helpdesk offer up-to-date tools.

Supplier Due Diligence, Certifications, and Digital Tools

Modern procurement is digital, secure, and transparent.

Use SAP, Oracle NetSuite, Zoho Inventory, Slack, Teams, and Zoom to manage and document every step.

Check supplier trade and quality history with Panjiva, ImportYeti, ImportGenius, Trustpilot, Alibaba Verified, and Made-in-China Audited.

Case Study: Optimizing an International CNC Project

A US medical equipment OEM needed fast-turn, FDA-compliant aluminum housings for global distribution. We sourced 6061-T6 aluminum, applied [clear anodizing](https://www.fictiv

.com/articles/aluminum-anodizing), and used laser marking for UDI codes.

DFM reviews were managed via Teams, prototype samples were couriered using DHL, and batch certifications supplied by SGS. Final QC was live-streamed via Zoom before global air shipment.

This cross-border, cross-industry workflow delivered defect-free, certified parts on time, every time.

FAQs: Common Questions About OEM CNC Parts Production and Supply Chain

Q1: Do you support prototyping and small batches?

Yes, via Prime, Protolabs, Fictiv, Hubs.

Q2: Which payment methods are safest?

Wise, PayPal, Alibaba Trade Assurance, HSBC L/C.

Q3: Is NDA/IP protection standard?

Always—see Nolo NDA Templates and China IPR Helpdesk.

Q4: Do you offer all export documents?

Yes—COO, MSDS, HS code.

Q5: Can I audit the factory?

Yes—book a video tour via Alibaba or Made-in-China.

Q6: How do I see real client reviews?

Check Trustpilot or request direct client contacts.

Q7: What if I need special finish/certification?

We deliver SGS, Bureau Veritas, Intertek reports on request.

Q8: Can I get technical DFM support and rapid quoting?

Yes—upload files at PrimeCustomParts.com, Hubs, MFG.com.

Q9: How do I manage logistics and global tracking?

We provide real-time tracking with DHL, FedEx, Maersk, and others.

Conclusion

Sourcing CNC metal parts at a global standard means combining the right technical data, digital tools, robust compliance, and a network of proven resources. With these platforms and best practices, you secure every project milestone—from drawing to delivery.

Contact Us

Have a technical question or a new project?

Visit PrimeCustomParts.com or email [email protected] for a no-obligation review and instant quote.

Prime delivers one-stop CNC solutions worldwide, serving North America, Europe, Middle East, Australia, and beyond.