5 Common Metal Stamping Parts and Where They’re Used

Metal stamping transforms flat sheets into high-strength parts with perfect repeatability. At Prime, our 12 stamping presses produce over 2 million parts monthly for global industries.

The five most stamped metal parts are brackets (50% automotive use), electrical contacts (gold/nickel-plated), shielding cans (EMI protection), washers (M6-M24 sizes), and hinges (300,000-cycle durability). Each serves critical functions in electronics, vehicles, and machinery.

Let’s examine these workhorse components:

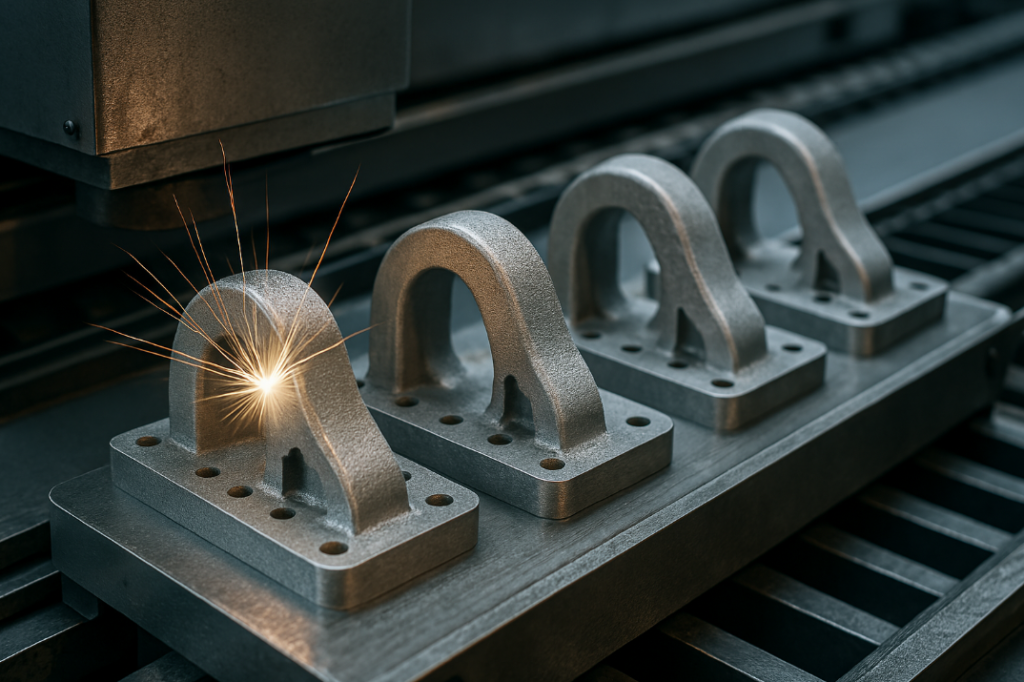

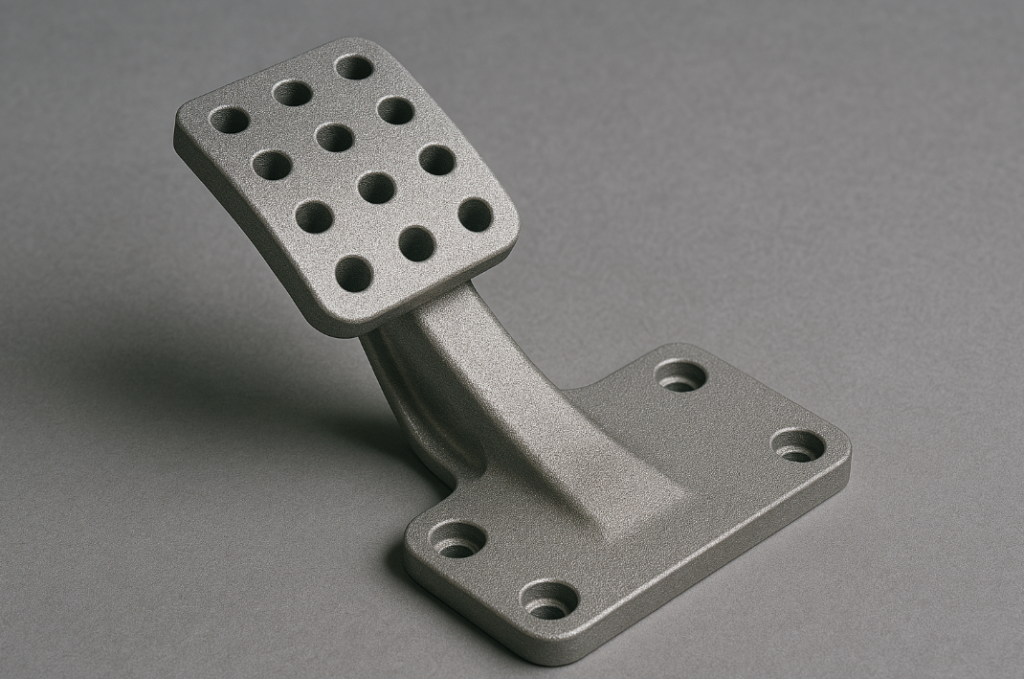

1. Mounting Brackets – The Automotive Backbone

Every car contains 120-200 stamped brackets for structural support.

**Prime’s stamping data shows:

- 2mm cold-rolled steel most common

- ±0.1mm tolerance ensures proper fit

- Powder coating prevents rust

Used for engine mounts, seat frames, and sensor holders**

Bracket Specifications

| Feature | Typical Value |

|---|---|

| Thickness | 1.5–4mm |

| Material | SPCC steel, 5052 aluminum |

| Finish | Zinc plating, powder coat |

| Production Speed | 800–1,200 pieces/hour |

2. Electrical Contacts – Powering Modern Devices

Precision-stamped contacts ensure reliable current flow.

**Our medical device clients require:

- 0.3mm beryllium copper springs

- Gold plating (0.5–1.5μm) for conductivity

- 10-million-cycle durability

Found in switches, relays, and battery terminals**

Contact Material Comparison

| Material | Conductivity | Cost | Common Use |

|---|---|---|---|

| C1100 Copper | 100% IACS | $$ | Home appliances |

| Beryllium Copper | 22% IACS | $$$$ | Aerospace connectors |

| Nickel Silver | 15% IACS | $$$ | Audio equipment |

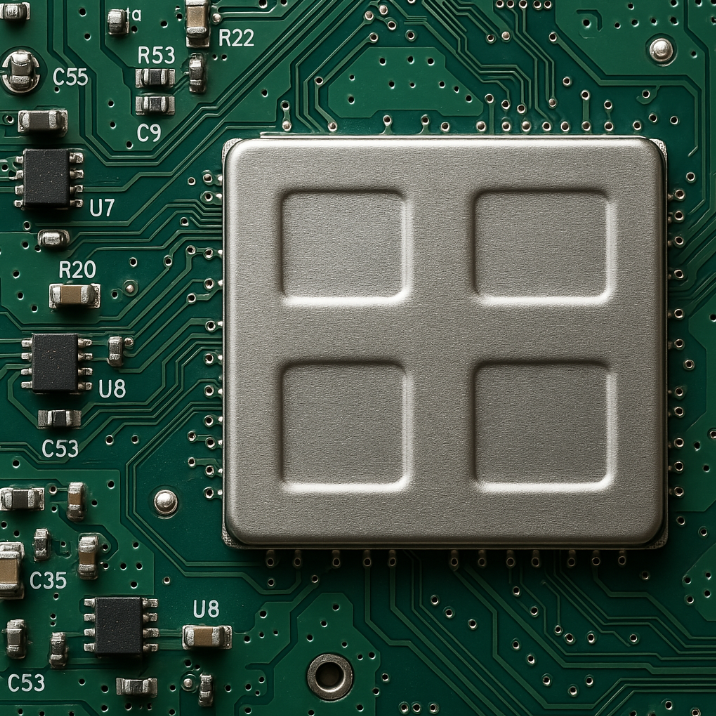

3. EMI Shielding Cans – Protecting Electronics

These Faraday cages block electromagnetic interference.

**Smartphone manufacturers demand:

- 0.2mm stainless steel cases

- Laser-cut ventilation slots

- Snap-fit designs for easy assembly

Critical for 5G modules and IoT devices**

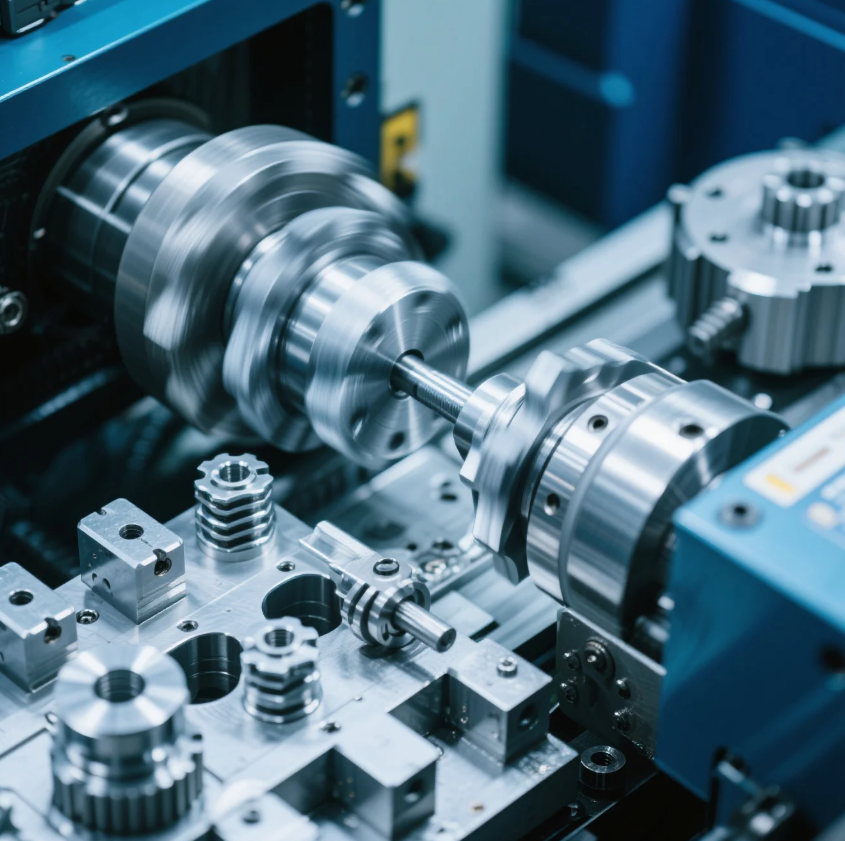

4. Washers – The Unsung Heroes

Stampings prevent bolt loosening and surface damage.

**Industrial equipment uses:

- M6-M24 standard sizes

- Hardened 65Mn steel for heavy loads

- Blue-dyed lock washers

Essential in construction and machinery**

Washer Types Breakdown

| Type | Function | Thickness |

|---|---|---|

| Flat | Distribute load | 0.5–3mm |

| Spring | Prevent loosening | 0.8–2mm |

| Shoulder | Align components | 1–5mm |

5. Hinges – Smooth Motion, Every Time

Stamped hinges outperform cast versions in cost and weight.

**Our best-selling designs:

- 1.2mm 304 stainless steel

- Self-lubricating bushings

- 180° rotation without sagging

Used in industrial cabinets and medical devices**

Conclusion

From car frames to smartphones, these five stampings — brackets, contacts, shields, washers, and hinges — form hidden infrastructures across industries. Prime’s ISO-certified stamping lines deliver these components with <0.2% defect rates to 37 countries. Need durable, precision metal parts? We stamp success.