High‑Precision CNC Metal Parts: How to Customize for Aerospace and Automotive?

CNC buyers often suffer from miscommunication1 or poor part consistency2. These issues slow down critical programs.

Aerospace and automotive systems depend on high-precision CNC parts1. They require tight tolerances2, certified quality, and traceable workflows.

Without these, parts may fail under stress. Here’s how we help solve this—from idea to delivery.

What Is High‑Precision CNC Metal Parts?

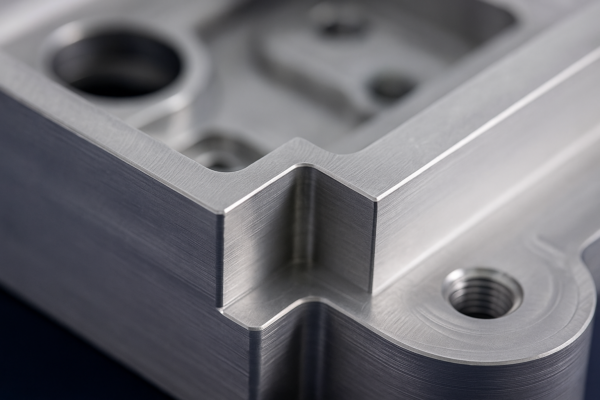

High-precision CNC parts often hold tolerances within ±0.005 mm. Both NASA and Boeing require such precision for mission-critical parts.

These components include aircraft hinges, engine mounts, turbocharger parts, and EV battery fittings. We use 5-axis CNC centers1 and Swiss-type lathes2 to reach these specs consistently.

Key Metrics of Precision CNC Parts:

| Feature | Standard CNC Parts | High‑Precision CNC Parts |

|---|---|---|

| Tolerance Level1 | ±0.1 mm | ±0.005 mm |

| Surface Finish2 | Ra 3.2–6.3 µm | Ra 0.2–0.8 µm |

| Measurement Tools | Calipers | CMM, Optical Profilometers |

| Typical Users | Hardware, Fixtures | Aerospace, Automotive |

According to ASM International, parts with micro-level precision reduce assembly errors by 70%. We consistently deliver that accuracy.

How to Customize CNC Machined Parts?

Customization means working from design to fully inspected components1. Prime streamlines this2.

Our Proven Workflow:

- Design Submission – .STEP, .IGES, .DWG, .PDF

- DFM Optimization1 – Based on SME.org best practices

- Material Selection – From aluminum, steel, titanium to brass

- Tolerance Definition2 – As per ISO 2768-1

- Prototype Delivery – Validated via CMM inspection

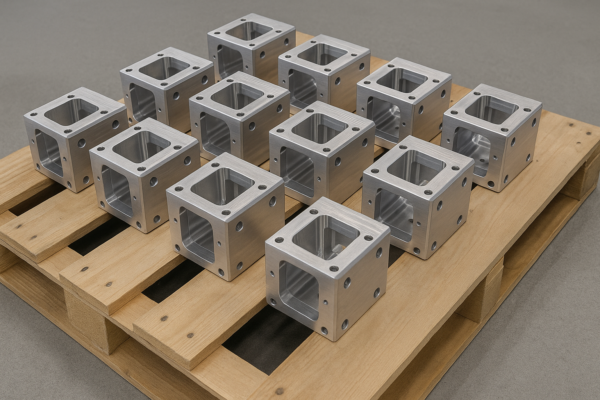

- Batch Production – Up to thousands per order

- QC and Packaging – 100% inspection, export-grade boxes

- Logistics – Air, sea, or express shipping

“Prime handled our aerospace bracket3 with unmatched precision and speed4.”

— Engineering Lead, UK Aerospace OEM

Real-World Applications in Aerospace & Automotive

Our CNC components3 power thousands of mission-critical systems4. Here are key use cases.

Aerospace Use Cases

- Engine Mounts3 – Must withstand vibration and thermal stress

- Valve Housings4 – Require high corrosion resistance

- Flight Control Hinges – Demand micron-level accuracy

- Heat Shield Supports – Must handle extreme temperatures

- Certified by NADCAP-quality auditors

Automotive Use Cases

- Brake Pistons & Discs – Require precise surface hardness3

- Turbocharger Flanges – Thermal cycle resistance

- EV Battery Casings – EMI shielding and exact clearances

- ECU Housings – Fit-for-purpose with tight tolerances

“Their turbine bracket cut our scrap rate by 60%. We saved months.”

— Procurement Manager, German EV Startup

How to Choose High‑Quality CNC Service Providers?

Choosing a reliable CNC partner3 reduces risk4. Here’s what matters most:

Essential Selection Criteria:

- ISO / AS9100 Certification3 – Must be up to date (IAQG)

- Advanced Machinery – Multi-axis CNC, Swiss-type lathes

- Comprehensive Inspection4 – CMM, projector, hardness testers

- Engineering Support – DFM feedback, revision control

- Prototype Capability – Quick samples, low MOQ

- Transparent Communication – Clear updates in English

Why Prime Stands Out

| Requirement | Prime’s Advantage |

|---|---|

| Certification | ISO 9001, AS9100, SGS audits3 |

| Machine Park | 10 CNC lines incl. 5-axis and Swiss lathes |

| QC Tools | Zeiss CMM, profilometers, hardness testers |

| Experience | 20+ years in aerospace and automotive sectors4 |

| Packaging | Rated export crates and ISPM‑15 compliance |

| Logistics | FedEx, DHL, Maersk for global shipping |

“Their DFM feedback early prevented costly reworks later.”

— Project Engineer, US Heavy Equipment Manufacturer

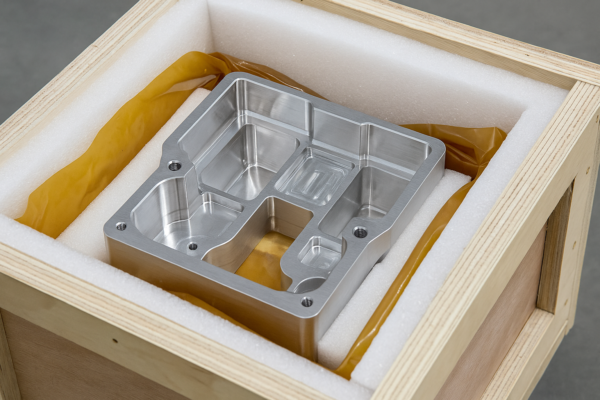

Packing & Shipping: Zero-Damage Delivery

Prime uses best practices to protect your order:

- Moisture-proof vacuum sealing3

- Foam inserts protect delicate shapes

- Bar-coded ISPM-15 wood crates

- HS-coded export labeling

- Secure palletization per freight standards4

- Trusted carriers: FedEx, Maersk, DHL

This safeguards components even in long-haul transit.

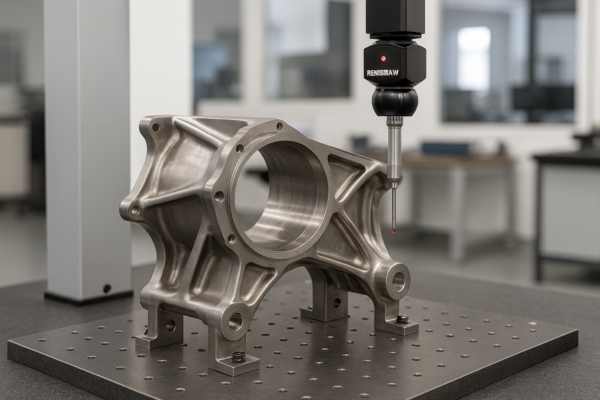

Quality Assurance at Every Step

Prime’s QA procedures include:

- CMM dimensional verification3

- Surface roughness checks4

- Hardness testing for steel parts

- Batch traceability and certifications

- FAI inspection reports

- Conformance to GD\&T standards and ASTM sampling

“Their inspection rigor exceeds many OEM labs.”

— Quality Manager, Canadian Aerospace Supplier

Contact Us & Free Quote

Ready to start your precision CNC project? Contact Prime today:

🌐 primecustomparts.com

📧 [email protected]

Receive a free DFM review, fast quote, and expert guidance. Let’s ensure your parts meet mission-critical needs.

❓ FAQs

1. What materials are supported?

Aluminum, steel, titanium, brass, copper. All with certifications.

2. What’s your MOQ?

From 1 prototype to full production runs.

3. What is the machining tolerance?

±0.005 mm. Tighter tolerances available on request.

4. How long is lead time?

3–7 days for samples; 10–20 days for production.

5. Which files do you accept?

.STEP, .IGES, .DWG, .DXF, .PDF, others by request.

6. Do you provide inspection reports?

Yes: CMM, FAI, material certs, and more.

7. Do you ship internationally?

Yes. We ship worldwide via air, sea, or express.

🏁 Conclusion

Choose Prime for precision CNC parts that meet aerospace and automotive standards. We combine 20+ years of experience, advanced machinery, ISO certification, and global shipping to serve your mission-critical needs.

📩 Please visit primecustomparts.com or email [email protected] to request your free quote and design review today.

Ready to elevate your CNC sourcing? Let’s get started.