How Die Forging Powers Aerospace & Automotive Manufacturing?

Die forging is a manufacturing technique that shapes metal into precise parts using high-pressure equipment1. Imagine you have a metal piece and a mold; a big press applies force to shape the metal exactly as needed. This method ensures strength2 and uniformity, making it essential in aerospace and automotive industries.

What Is Die Forging? – Definition, process flow, use of press/molds.

Die forging1 is a process where metal is heated and placed into a mold2, then shaped using a powerful press. The process starts by heating the metal to a specific temperature to make it malleable. Next, the heated metal is placed into a mold2, which is then squeezed by a press. The die, or mold2, gives the metal its final shape, ensuring precision and reliability.

Engine Parts

Engine parts like pistons and crankshafts need to be perfectly shaped for optimal performance. The high precision1 and strength required in aerospace and automotive engines mean die forging2 is a preferred method.

Engine parts made through die forging

Turbine Blades

Turbine blades in aircraft engines must withstand high temperatures and intense stresses. Die forging1 ensures that these blades are precisely formed, which is critical for safety and efficiency.

Turbine blades made through die forging

Structural Components

Structural components in aircraft, like wings and fuselage parts, need to be lightweight but strong1. Die forging2 helps manufacture these components with the necessary properties.

Structural components made through die forging

Aerospace Applications – Engine parts, turbine blades, structural components.

Die forging plays a crucial role in making aerospace components1 like engine parts, turbine blades2, and structural components. Engine parts need precise dimensions and materials to ensure efficient operation. Turbine blades must be strong enough to withstand high temperatures and stress. Structural components must be lightweight yet robust to ensure aircraft safety.

Engine parts made through die forging

Engine Parts

Engine parts like pistons and crankshafts require high precision and strength. Die forging1 ensures these parts are manufactured correctly, leading to better engine performance2.

Turbine Blades

Turbine blades need to be formed to precise specifications to withstand the high temperatures and stress of aircraft engines. Die forging1 ensures these parts are formed accurately.

Structural Components

Structural components need to be lightweight yet strong1. Die forging2 allows for the manufacture of these components with the right properties for safety and efficiency.

Structural components made through die forging

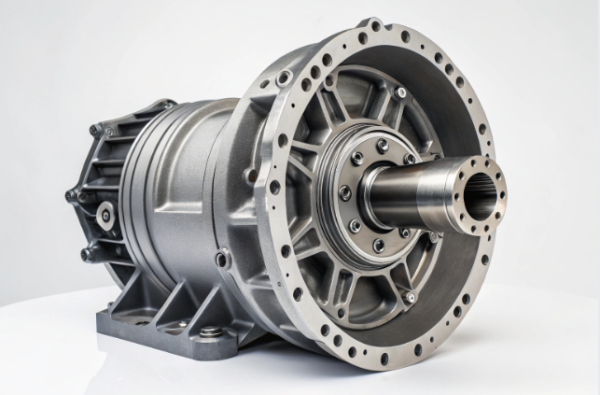

Automotive Applications – Gears, shafts, high-strength engine parts.

Die forging is also vital in the automotive industry for creating gears, shafts, and high-strength engine parts1. Gears need to operate smoothly and efficiently. Shafts must be robust and durable. High-strength engine parts like cylinder heads and connecting rods require materials that can withstand extreme pressures and temperatures.

Automotive parts made through die forging

Gears

Gears in automobiles must operate smoothly to ensure a seamless driving experience. Die forging1 ensures that gears are precision-machined2 for optimal performance.

Gears made through die forging

Shafts

Shafts in engines and transmissions need to be sturdy and durable1. Die forging2 ensures that these components are formed with the right materials and dimensions.

Shafts made through die forging

High-Strength Engine Parts

High-strength engine parts1 like cylinder heads and connecting rods require materials that can withstand extreme pressures and temperatures. Die forging2 ensures these parts are made with the necessary strength and durability.

High-strength engine parts made through die forging

Case Study: Real-World Examples – Showcase successful die forging projects.

One real-world example of successful die forging1 is a company that used the process to create a new type of piston for an automotive engine2. The company heated the metal to the right temperature, placed it into a mold, and used a press to shape it. The result was a piston with improved durability and a longer lifespan.

Conclusion

Die forging is a critical process in the aerospace and automotive industries1, ensuring that parts are made with the necessary precision and strength. From engine parts to turbine blades and gears, die forging2 plays a vital role in creating reliable and efficient components for aircraft and vehicles.

-

Discover how these industries leverage die forging for manufacturing high-quality parts essential for performance and safety. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Explore this link to understand die forging’s significance and its applications in creating strong, precise components. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩