How do you know if something is injection molded?

Image: Molded plastic component showing surface artifacts.

Buyer: I just received a sample part from a new supplier. It looks pretty good—but how do you know if something is injection molded?

Engineer (from Prime): Great question. Many clients ask us the same. You can usually tell by checking for certain physical signs.

How to tell if something is injection molded?

Buyer: Okay—so where should I look first?

Engineer: Start with the parting line. That’s where the two halves of the mold come together. If you see a faint seam running across the part—especially around the sides—it’s a strong indicator.

Buyer: Got it. Anything else?

Engineer: Yes—flip the part over. If it’s injection molded, you’ll often find circular marks from ejector pins. These tiny indentations are left behind when the part is pushed out of the mold.

Summary:

Want to know how to tell if something is injection molded? Look for seam lines, ejector marks, and traces of where the plastic entered the mold.

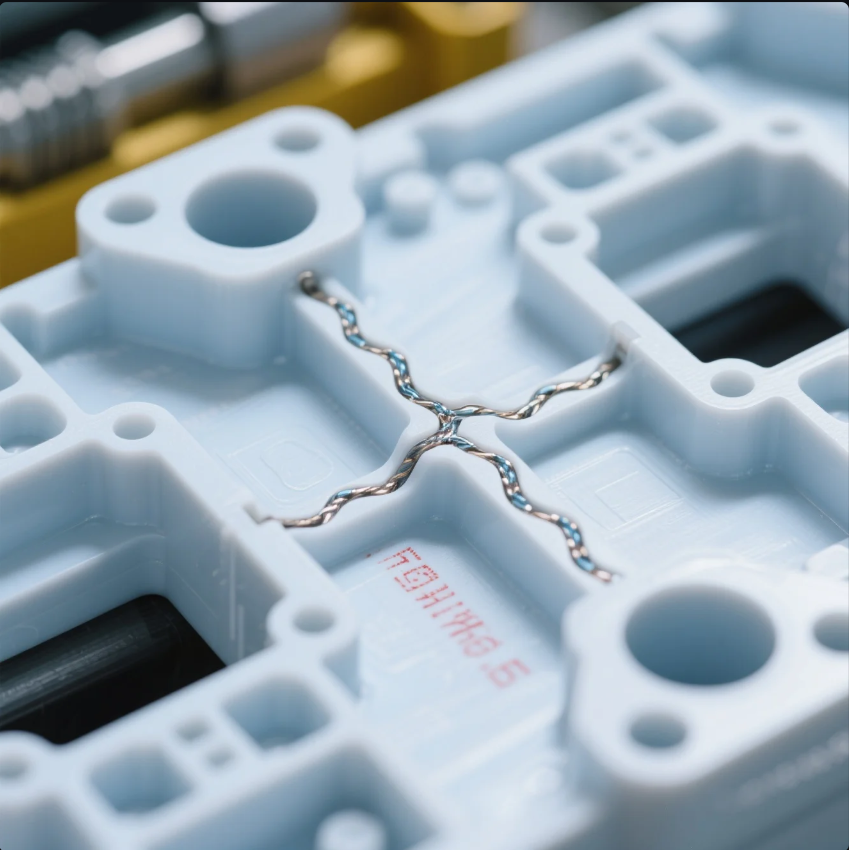

What are injection molded signs?

Buyer: The part I have also has built-in clips and some internal ribs. Are those injection molded signs?

Engineer: Absolutely. Molded parts often include functional design features like:

- Snap-fits

- Mounting bosses

- Draft angles

- Molded-in logos or numbers

These are hard to achieve through other manufacturing methods like CNC or 3D printing.

Buyer: So if I see those, it likely came from a mold?

Engineer: Yes—especially if the details are clean and repeatable.

Summary:

Integrated features like clips, ribs, and molded logos are classic signs of molded parts.

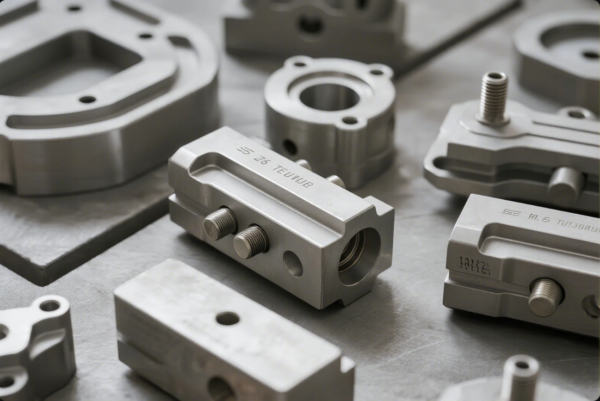

What are the identifying features of injection molding?

Buyer: Some parts have swirl-like lines or tiny ripples on the surface. Are those defects?

Engineer: Not necessarily. Those are called flow lines. They show how the molten plastic filled the mold cavity.

Buyer: So they’re not a problem?

Engineer: Only if they affect function or appearance. At Prime, we optimize mold flow to reduce those patterns and keep surfaces smooth.

| Feature | Description |

|---|---|

| Parting Line | Mold seam—typical but should be minimal |

| Ejector Pin Marks | Circles left by pin ejection |

| Gate Vestige | Tiny leftover plastic at the injection site |

| Flow Lines | Swirls from plastic flow direction |

| Uniform Wall Thickness | Indicates proper design for molding |

Summary:

How do you know if something is injection molded? These surface features—when consistent—are your strongest clues.

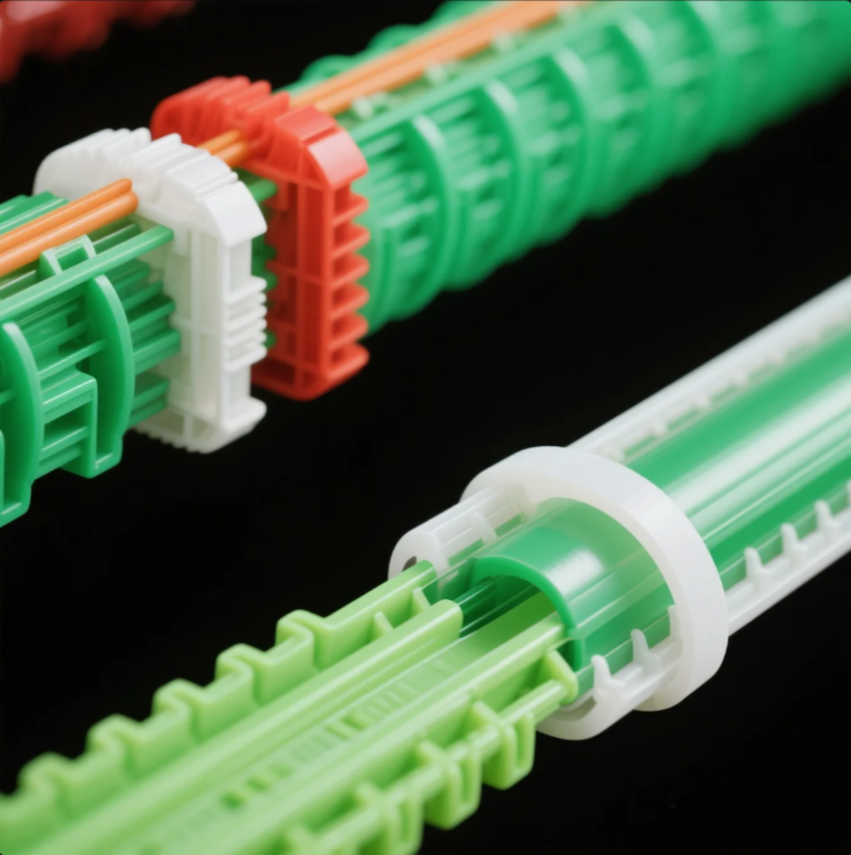

What does injection molding look like?

Buyer: Some parts are glossy, others have a matte finish. Does that mean they weren’t molded?

Engineer: Actually, both can be injection molded. The finish depends on the texture inside the mold.

Buyer: So what should a good molded part look like?

Engineer: It should have:

- Clean surface texture

- No sink marks or warping

- Consistent color and wall thickness

- Optional branding or serial numbers molded in

At Prime, we offer multiple finishes—like EDM matte, VDI grain, or even mirror-polish for cosmetic parts.

Summary:

Molded parts look clean, professional, and consistent—whether textured or glossy.

Frequently Asked Questions (FAQ)

❓ Can 3D printed parts look like molded ones?

Engineer: Sometimes. But 3D prints usually show visible layers and texture inconsistencies.

❓ Are all plastic parts injection molded?

Engineer: No. Some are thermoformed, machined, or blow-molded. We help clients choose the right process at Prime.

❓ How do you know if something is injection molded?

Engineer: Look for parting lines, ejector pin marks, molded-in features, and consistent wall thickness. These are solid indicators.

❓ What materials are commonly molded?

Engineer: ABS, PC, PP, POM, and nylon (PA) are among the most used in industrial applications.

Conclusion

Buyer: Thanks—I feel a lot more confident now. So if I ever wonder, “how do you know if something is injection molded?” I’ll just inspect the surface, structure, and marks.

Engineer: Exactly. And if you need help reviewing a part or preparing a mold-ready design, Prime is here to help.

Looking to validate your part design or quote your next injection molding project?

Contact Prime today for free feedback, DFM suggestions, or sample evaluations. We’ll help you turn ideas into precision-molded reality.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com